As a kid, one of my favorite holidays was Halloween. There’s something about that time of year that absolutely appealed to me then, and still does today. The leaves changing color and falling off the trees combined with the anticipation of free candy and stories of ghosts and haunted houses drove my love for the season.

Since Halloween is right around the corner, I thought it would be a perfect time to take a look at some of the ghosts in duct systems that are often tracked down by progressive HVAC companies. Some of these issues are directly caused by the duct system itself while others are an indirect result of its influence. Let’s take a look at some of the most common duct-related ghosts that you might be called on to bust.

MYSTERIOUS CLOSING DOORS

No ghost story is complete without the mention of doors closing on their own. Due to the layout of many HVAC systems across the country, this is a very real haunt that many of your customers deal with regularly. It’s often caused on a smaller scale by something invisible, but it’s typically a fan instead of a supernatural occurrence. The two most common places this happens are in homes with central returns and commercial kitchens.

Pressure imbalances created due to depressurization can create some pretty scary airflow situations within a building. When airflow is out of balance and out of control, the stage is set for “airflow competition.”

Central returns combined with interior door closure can cause marginally open doors to shut, simply by the fan in the air-handling equipment coming on. The positive pressure created in these rooms can be enough to close interior doors if the conditions are right.

In a commercial setting, kitchen exhaust and makeup air fans that are out of balance with each other can create a similar situation. In a commercial building, however, the effect isn’t as pronounced on interior doors due to their heavier construction. Instead, exterior doors are impacted so that an airflow imbalance can cause them to be nearly impossible to open to enter the building.

One of the tricks I was taught at my first air-balancing class was to crack the exterior door of a restaurant to see if you could feel air rushing in. If you could, there was an opportunity to bust an invisible problem. If you could barely open the door, the opportunity was that much greater.

By assuring that proper airflow is achieved and pressure imbalances are minimized, this problem can often be taken care of through specific testing, adjustments, and duct renovation work.

WAILING REGISTERS

Just like those scary wails often heard in haunted-house movies, your customers can have mysterious wails coming from their HVAC systems. The most common sort of wail is typically tied to air noises made from the grilles and registers.

Poorly selected grilles and registers can cause excessive velocities at the face of the grille or register. As air passes through the vanes, a wail is produced due to the speed of the air. For many customers, their response can range from being annoyed to feeling like they’re on the brink of insanity.

Pay attention to the desired airflow from a grille or register and make sure it’s within acceptable velocity limits to keep the wailing sound from occurring. Design supply registers for a face velocity under 500 fpm and return grilles in the 300-500 fpm range to keep the system quiet and wail-free.

With registers and grilles being the most visible parts of an HVAC system, you can offer performance-grade grilles and registers to reduce noise issues that drive customers batty. In addition, these performance-grade grilles and registers have excellent visual appeal.

BANGING DUCTS

Loud, unexpected noises are the foundation of any good ghost story. When a duct system is subjected to certain conditions, the noise it makes as it turns on can be startling, too. Many of us have dealt with panned floor joist oil-canning as they are walked on. This problem can often be tracked down with a good ear, but what about those times the banging isn’t as obvious?

One such condition is created when restricted ducts are installed. Excessive static pressure can cause movement in metal duct as the fan in the air-handling equipment is so desperately trying to move air. One of the most common variables in the banging ducts is the condition of the air filter.

When the filter is new, there is more pressure in the return side, causing ducts to bang each time the fan comes on. As the filter starts to load up with dirt, or is replaced with a more restrictive media such as a pleated filter, the problem seems to mysteriously disappear.

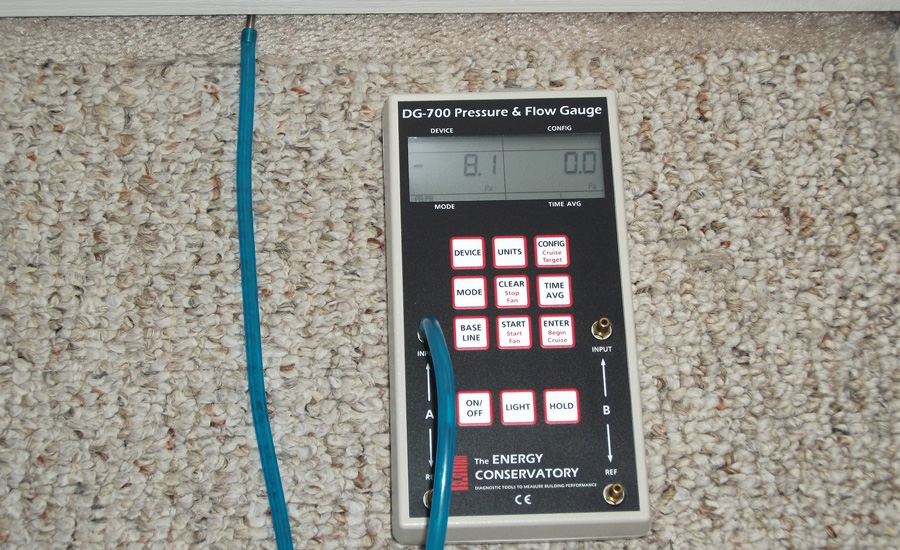

Static pressure testing reveals the answer to this intermittent issue. In our classes, we teach to compare measured static pressures against National Comfort Institute (NCI) static pressure budgets to see which side of a duct system needs the most attention. Keep in mind that this problem could still occur with acceptable static pressures in ducts made of extremely light-gauge metal.

One of the loudest, most abrupt, and hardest to diagnose noises is the sound of a carbon monoxide alarm. Sadly, this is one of the most misdiagnosed ghosts in the system due to lack of proper training, testing, and protocols to follow.

To track down something that’s invisible like carbon monoxide, you must understand it and have the right testing equipment to uncover it. Otherwise, it remains hidden. Unfortunately, this isn’t enough. You also need to know where to test for carbon monoxide. All the test instruments and understanding you can assemble are useless if you look in the wrong place.

To find this invisible killer and determine the reason for the alarm, you have to follow a process that allows you to systematically eliminate potential causes. Once potential causes are eliminated through proper measurements, you’re left with the real issue causing the problem.

HOT AND COLD ROOMS

Another problem that tends to appear and disappear randomly is an uncomfortable room in the home. This room may be comfortable at one point in the day and unbearable at another. Problems of this sort can be difficult to solve because they may go beyond the traditional side and expand into the building side of the duct system.

When confronted with resolving hot and cold rooms, begin by determining the time of day it’s taking place. This can give you a lot of clues regarding the circumstances surrounding the onset of the problem. If you’re lucky, this information will lead you to the source of the complaint.

The two most common issues tied to this problem are related to duct losses and room surface temperatures impacted over the course of the day. In your diagnosis, start with the duct system to assure it isn’t an issue with duct system losses over the course of the day. Expand into building-side issues to explore insulation and infiltration problems as contributing factors next.

As you can see, many issues you encounter are invisible in nature and have to be made visible to customers through testing and diagnostics. Unlike ghost stories and haunted houses, these issues are very real to your customers and they want them solved.

I hope you enjoyed this lighthearted look at some of the issues you encounter on a daily basis and that you take full advantage of busting your customer’s comfort ghosts.

Publication date: 10/26/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!