Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were on their first service call of the winter season. A customer wanted them to perform service on their furnace to make sure that the unit was in good working order for the winter.

Bob and Tim had arrived and were talking to the customer when he said, “I want you to go over my gas furnace. I have had it for about six years and have never had a service call. It is a high-efficiency furnace and has been giving good service, but I think it’s time to have a professional look it over.”

Bob told the customer, “We are well schooled on this type of furnace. We go to a service refresher class every year. This has been a very popular model of furnace and gives reliable service.”

Bob and Tim went to the basement where the furnace was located and did a visual inspection. They removed the filter and looked at the fan motor which seemed to be in good shape and had no buildup of dust on the fan wheel. They took a flashlight and examined the cooling coil and found it to be clean. They oiled the motor and replaced the filter.

Bob then told Tim to go upstairs to the thermostat and turn it to heat and turn the thermostat up. Meanwhile Bob turned off the disconnect switch at the furnace so that he could control the furnace startup from the furnace location.

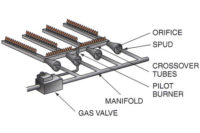

When Tim returned, Bob said, “When we start the furnace look through the glass porthole and watch the burner light from the pilot light. This furnace has a hot surface ignition system and you should see the hot surface igniter start glowing and then the pilot light will light. When the pilot light ignites, the electronics will prove that there is a pilot light burning before allowing gas to the main gas valve.”

Tim flipped on the switch and looked through the sight glass to watch for the hot surface igniter. He said, “I don’t see anything. I don’t hear anything. I don’t think anything is happening in this furnace. What do we do next?”

Bob said, “Turn the power off and let’s remove the burner access panel.”

After they had removed the burner access panel, Bob said, “Look at the hot surface igniter and see what you see.”

Tim took a flashlight and looked at the hot surface igniter and said, “It looks okay, but I can’t get a real good view of it.”

Bob said, “Remove one of the wires from the bottom of the igniter and do a continuity test across the igniter.”

Tim removed a wire from the bottom of the igniter and used his Ohmmeter to see how much resistance the hot surface igniter had and it was open circuit. Tim said, “This igniter is no good. It will have to be replaced. I think we have one on the truck for this model furnace.”

They removed the old igniter and before Tim could take the new one out of the box, Bob said, “Before you remove it from the box remember that you do not touch the igniter surface with your hands. The oil on your hands can affect that delicate metal and may cause a premature failure of the next igniter.”

Tim installed the new igniter and flipped on the switch and looked through the porthole and said, “This one is glowing. I heard a click and the pilot light came on. The burner should ignite next, but it didn’t ignite. What do we do now?”

Bob said, “It looks like the flame rod in the electronic circuit is either not sending the signal or the circuit is not working in the electronics. The first thing we should do is change the flame rod for a new one and try again. If the main gas valve then opens, we will have solved the problem. If it does not open, we will get into the electronics. The circuit board may be bad.”

They changed the flame rod and started the system up again. The pilot ignited in just a few seconds, the main gas valve opened, and the burner ignited from the pilot light.

Bob said, “It looks like the burner section is all working now. Now let’s wait and let the fan motor start up and make sure it starts correctly. Then we will run the furnace a few minutes and measure the temperature rise across the furnace. Then we can turn the furnace off and wait for the fan to shut down after cooling the furnace and we will be good to go.”

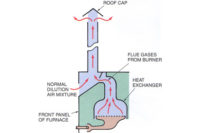

The fan started up on time and they measured the temperature rise across the furnace. The furnace nameplate explained the minimum and maximum temperature rise across the furnace should be between 40° and 70°F.

Tim then asked, “Would you please explain temperature rise across the furnace to me again.”

Bob said, “If there is too much air flowing through the system, it is not good for the furnace and the temperature rise would be low, maybe a 30° rise. If there was not enough airflow across the furnace, the temperature rise would be high, above 70°. So the furnace is designed to operate between a 40° rise and a 70° rise. If it falls outside these bounds, you either have to slow the air down or speed the air up by adjusting the fan speed.”

Tim said, “The temperature rise across the furnace is 60°. This looks well within range.”

Bob agreed and they removed their instruments and turned the thermostat back to normal and waited for the fan to shut off.

Bob said, “This furnace system is working just as it should.”

While riding away from the job, Tim said, “That was a good exercise. The system had two problems, the defective igniter and the defective flame sensing rod. We don’t see very many systems that have two problems. Most of the systems we have worked on have had only one problem to solve. I guess that would be called a good learning lesson.”

Publication date: 10/19/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!