Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were doing a routine seasonal service call on a high-efficiency furnace when Bob said, “The furnace that we serviced last was a standard efficiency furnace with an efficiency of about 80 percent. Those furnaces have been around for many years. The more modern high-efficiency furnaces can be as efficient as about 97 percent or slightly more.”

Tim asked, “Why were the older furnaces so inefficient compared to the more modern furnaces?”

Bob explained, “The biggest problem has always been dealing with the products of combustion. The earlier furnaces used the heat from the flue gases to draft the products of combustion up a flue (Figure 1). The fact that hot gases rise was the principle. The hot gases have usable heat in them; about 20 percent of the heat input was used to cause these gases to rise up the flue. When it became more advantageous to extract that additional heat, more equipment had to be added to the furnace. When the flue gases are cooled below about 300°F, the moisture in the flue gases begins to condense, leaving slightly acidic liquid water. This is very hard on any ferrous metals in the furnace or vent system. Ferrous metals are the iron or steel that the furnace is made of. Plastics and stainless steel are not affected.

“Another thing that makes a furnace inefficient is the combustion air used to burn the gas. The combustion air in older furnaces was air that was removed from the structure. When that air was used for combustion air, it pulled a slight vacuum on the structure and the air was replaced with air that infiltrated into the structure from around the doors and windows. As you know, people have been building tighter and tighter houses and that infiltration air was becoming harder to find for combustion.

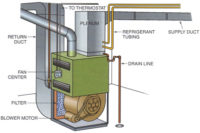

“Furnace manufacturers began to build furnaces that have a closed combustion system that gets the combustion air from an incoming vent from the outside (Figure 2). These gases leaving the furnace are not near as hot as they used to be; they may be as low as 95°. Combustion air that is at that low of a temperature will not rise, so the manufacturers built in a small combustion fan that moves the air. With this low temperature, the flue gases can be vented through certain plastic pipes.”

Tim then said, “Boy, that is a mouthful of words; however, the methods seem easy to understand. I am assuming that this extra equipment is where the extra service comes in.”

Bob said, “Yes, the extra equipment serves to move the flue gases through the system. The blower actually reverses the flow of the flue gases. The natural flow is for the flue gases to rise. That also means that the hottest flue gas is in contact with the hottest leaving furnace air temperature. To get the most out of the flue gases, it is necessary for the gas to be in contact with the return air in the furnace. The last heat exchanger is the one that is in the coolest furnace air stream, the return air. That heat exchanger is called the condensing heat exchanger and is often a coil, similar to a refrigerant coil, made of stainless steel to withstand corrosion (Figure 3). The air leaving that coil is in the 90° range and very humid. Most of the moisture is condensed out of the exhaust, but in cool weather it appears as a fog, much like a clothes dryer vent. The condensing of the moisture gives the furnace more efficiency. Each pound of water that is condensed adds about 970 Btu of capacity to the furnace.”

Tim asked, “What extra things should we look out for with this furnace?”

Bob said, “Most of what we will look for is visual, plus the typical filter change and oiling of motors:

1. Examine the vent piping to make sure it is pitched in the correct direction. The exhaust vent should be slightly uphill leaving the furnace. The intake vent should be slightly downhill towards the furnace.

2. Examine the plastic vent connections for traces of moisture leakage.

3. Examine the vent and intake for any trash, bird nests, or any other obstructions.

4. Examine the furnace condenser coil for signs of moisture leaks.

5. Change the air filter.

6. Check the condenser coil inlet to make sure there is no buildup of dirt or dust that would obstruct inlet air flow.

7. Make sure all supply registers are open.

8. Check the return air for obstructions.

9. Start the furnace and watch the burner startup sequence.

10. Observe the furnace fan startup.

11. Check the condensate drain system for the furnace.

“That is about it. Let’s get started.”

Tim went through the steps and the furnace operated correctly. He then said, “I believe that this furnace is good for another year. It is in good shape.”

Bob agreed and said, “It cost the customer some money to get this done, but it is worth it to know that everything is safe and operating correctly.”

Publication date: 12/22/2014

Report Abusive Comment