Home » Keywords: » ERV

Items Tagged with 'ERV'

ARTICLES

Indoor Air Quality Solutions for VRF Systems

OEMs offer ventilation options and upgraded filters to improve indoor air

Read More

Ventilation Safeguards for COVID-19 Should Combine Outside Air With Other IAQ Equipment

When it comes to COVID-19 protection, two (or more) technologies are better than one

Read More

Diagnose, Solve, and Improve Ventilation

Contractors educate homeowners on the role IAQ plays in their health, comfort

Read More

Energy Recovery Ventilator Market Worth $3.39 Billion by 2021

Increasing awareness of benefits, rising demand for improving IAQ are driving growth

August 5, 2016

Baiting the Hook with Energy Recovery Ventilators

Contractors suggest how to upsell ventilation systems to customers

Read More

Drury Hotels Use ERVs to Cost Effectively Treat Outdoor Air

Rotary energy recovery wheels make a difference

April 4, 2016

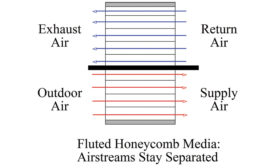

How to Provide the Best-Cost, Not Least-Cost, Option on New and Retrofit ERVs

The wheel potentially makes the difference in performance

Read More

Oct. 10, 2014: Zehnder America Introduces New US-Made HRV/ERV Air Distribution Components

Properly Matched Components Will Provide a Quiet System and Smoother Installation

October 10, 2014

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing