The compressor plays a crucial role in the operation and performance of air conditioning or refrigeration systems, because without this vital component, there would be no cooling for products or people. However, end users are increasingly seeking more than just reliable cooling from their systems; they want sustainable equipment with enhanced energy efficiency and environmentally friendly, low-GWP solutions.

Manufacturers have responded to this demand by developing innovative compressors that not only save energy but also employ low-GWP refrigerants. They proudly showcased these cutting-edge solutions at the AHR Expo.

Future-Proof Options

Embraco has been researching and developing compressors to be used with hydrocarbons such as isobutane (R-600a) and propane (R-290) since the early 1990s, said Michel Moreira, commercial refrigeration and aftermarket business director for North America at Nidec Global Appliance. He noted that many scientific studies prove their efficiency and negligible impact on global warming, which is why the company is committed to spreading awareness about the importance of natural refrigerants as the real future-proof solution.

“Today, 70% of our compressors sold globally, in both residential and commercial sectors, are used with natural refrigerants,” he said. “Natural refrigerants are future-proof (climate-friendly), which means they have no or minimal GWP and zero ODP. They are part of natural biogeochemical cycles and do not form persistent wastes in the atmosphere, water, or biosphere.”

At the AHR Expo, Embraco highlighted its efficient and low-noise variable-speed compressors, which include the VEMT, FMF, and VNEX families.

FUTURE PROOF: Michel Moreira said that Embraco’s NT and F Series compressors are future-proof, as they use natural refrigerants. (Staff photo)

“The VEMT is part of the VEM family and is suitable for applications such as glass door merchandisers and food service refrigeration equipment,” said Moreira. “It is the most energy efficient in its range of applications and has a range from 3 to 6 cc, which is suitable for low- and medium-temperature applications. End users will appreciate its energy savings, very low noise, and reliability in high-ambient temperatures.”

The FMF is a versatile portfolio that is designed for commercial refrigeration applications that require strict temperature stability, reliability, energy efficiency, and low noise, such as food retail, food service, and merchandisers (bottle coolers). Moreira said it offers displacements ranging from 6 to 15 cc and uses Embraco’s cutting-edge variable-speed technology, driving the speed according to the system’s thermal load and optimizing performance for energy consumption.

The VNEX was designed to be used in critical applications, such as large food service freezers and wide food retail glass door applications. According to Moreira, this variable-speed platform offers the highest energy efficiency level available in the commercial refrigeration segment for its capacity range. He added that this platform was designed to support customers' upcoming challenges with energy regulations, which impose tough targets for energy consumption while keeping tight limits for food preservation.

Fixed-speed compressors were also displayed, including the newest NTX, which is the next generation of the NT Series. Moreira said these compressors are designed for applications that demand robust cooling, such as multideck reach-ins and ice machines.

“All these products are future-proof being ready for natural refrigerants, such as propane (R-290),” he said. “With our entire portfolio, including compressors, condensing units, and new launches, we want to reinforce Embraco’s strategy to be a single trusted partner, which provides not only the compressor, but different sets to a whole cooling unit.”

Ready for A2Ls

The refrigerant transition was top-of-mind at the LG Component Solutions booth, and Jerry Edwards, senior manager of sales engineering, said LG is doing its part to ensure A2L readiness by developing components that will help customers launch new systems into the market in a timely manner.

“We are a rarity — a compressor manufacturer that provides competitive rotary and scroll compressors to major residential HVAC OEMs,” said Edwards. “At the Expo, we featured all platforms for the unitary market, to equip our OEMs for the upcoming major industry shifts, the HFC refrigerant phasedown, and heat pump electrification.”

To that end, LG highlighted its entire R-454B compressor lineup designed for heat pump applications. Edwards noted that LG’s single- and two-stage scrolls are more efficient than ever, built upon LG’s GEN3 technology, and ideal for entry- to mid-tier applications.

R-454B LINE-UP: LG highlighted its entire R-454B compressor line-up designed for heat pump applications, and Jerry Edwards was on hand to answer questions. (Staff photo)

“LG’s variable-speed rotaries are our most cost-effective variable-speed solutions, perfect for mid- to upper-tier applications,” he said. “LG’s R1 compressors are our most efficient variable-speed solution, perfect for high-tier applications. The R1 reflects LG’s innovativeness in a compact shell. We even upgraded this design with a vapor injection option for enhanced heat pump performance at lower outdoor ambient temperatures.”

Edwards said that the R1 compressor stands out due to its unique design and features. This includes variable-speed operation, which means it can operate across a wide speed range, enabling optimal temperature and humidity control in the conditioned space and adapting to the specific cooling or heating requirements of the environment.

“Another unique feature of the R1 compressor is its scroll mechanism with a pass-through shaft,” said Edwards. “Unlike traditional scroll compressors, the R1 compressor has a shaft that penetrates through the scroll, with bearings on either side. This innovative design reduces the side-loading of the mechanism, enhancing its performance and efficiency in delivering consistent heating or cooling capacity.”

He added that other features of the R1 include the fusion of rotary and high-side scroll technology, which provides enhanced efficiency and reliability; longer run cycles for improved air quality; and simplified structure.

Because A2L refrigerants are mildly flammable, contractors and technicians must receive specialized training on the safe handling of these refrigerants before installing and/or servicing these air conditioning systems, said Edwards.

“However, the behavioral characteristics of R-410A refrigerant (A1) and R-454B refrigerant (A2L) are reasonably similar, so contractors working on these systems will find most steps for service/installation are comparable to those they have become accustomed to,” he said.

Pivotal Year

This is a pivotal year in the refrigerant transition, with January 2024 marking the start of a 40% phasedown in HFC production and consumption, as authorized by the AIM Act, which will likely result in price increases for legacy refrigerants, said Ken Monnier, chief technology officer at Copeland. In addition, the approval of A2Ls in the Environmental Protection Agency’s (EPA’s) Significant New Alternatives Policy (SNAP) Rule 26 is expected any day, and it will formalize the introduction of A2Ls in commercial refrigeration.

“With some of the EPA’s compliance dates now less than a year away, we can expect to see the roll-out of A2L-optimized equipment later this year,” he said. “Copeland has been preparing for this transition and subsequent equipment production changes for many years. We’ve stepped up our domestic manufacturing capabilities to support an increase in A2L, A3- and CO2-optimized compressors, controls, and associated components, and we highlighted many of these solutions at the AHR Expo.”

On the commercial refrigeration side, Copeland displayed the YS*KAU R-290 scroll compressor, which has been optimized to take advantage of the EPA’s proposed R-290 charge limit increase of 300 to 500 grams in stand-alone refrigeration equipment. By using higher refrigerant charges, the compressor can effectively double currently available R-290 system capacities with a single condensing unit, said Monnier.

Copeland is committed to growing its comprehensive CO2 portfolio with the 4MTLS transcritical CO2 semi-hermetic compressor, noted Monnier. Designed to bolster the rising adoption of CO2 refrigeration in U.S. and global food retail markets, the compressor can be specified for medium temperatures and to support supercritical operation in CO2 booster systems.

On the comfort cooling side, Copeland highlighted its all-new oil-free centrifugal compressor that utilizes Aero-lift bearing technology to remove the complexities of oil management in air- or water-cooled chillers, without the costs and challenges of magnetic bearings. According to Monnier, Aero-lift bearing technology eliminates the need for complex electronics, sensors, and redundant backup bearings, enabling rapid restarting and smooth coasting to shut down during power disruptions.

Also featured was the Copeland 15T two-stage scroll compressor, which expands the capacity range for light commercial air conditioning and heat pump use and is optimized for lower-GWP A2L refrigerants to deliver sustainability and energy efficiency. This new line-up of A2L compressors will launch early this year. Additionally, Copeland scroll 40T fixed-speed compressors for commercial applications are engineered with enhanced vapor injection (EVI) technology to deliver higher capacities and improved efficiencies, even in low ambient or cold climate heat pump (CCHP) applications, said Monnier.

In preparation for the 2025 adoption of A2L refrigerants, Copeland’s portfolio of next-generation air conditioning compressors has been A2L-optimized for the addition of R-454B and R-32 refrigerants, said Monnier. This includes two-stage and both variable- and fixed-speed options to be used in air conditioning, heating, and heat pump applications for residential and light commercial sectors.

“Our innovative, single-stage, scroll compressors deliver optimized efficiency at key SEER2 and HSPF2 operating conditions, allowing OEMs to meet stringent Department of Energy (DOE) minimums,” he said. “Copeland’s two-stage scroll compressor — which won the 2023 AHR Innovation Award in the heat pump category — provides affordable comfort and energy efficiency. With its ability to run at lower capacity without stopping, it yields important benefits in humidity reduction and air quality.”

Even with all the regulatory changes this year, Monnier noted that “It’s an exciting time for the entire HVACR industry, and Copeland will continue to support our customers and stakeholders in every way possible.”

At the Front

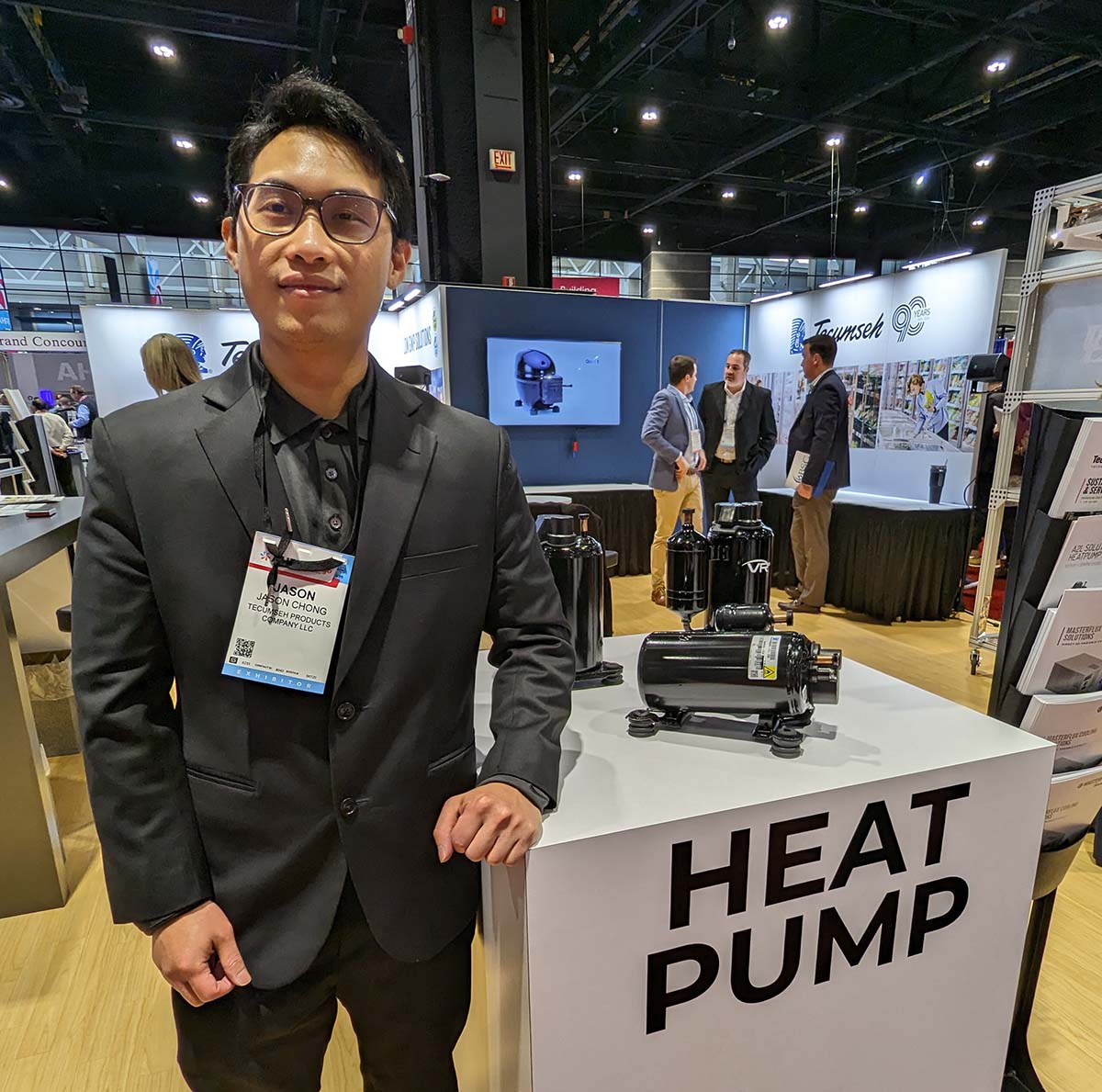

Following the implementation of the AIM Act, Tecumseh has been at the forefront of low-GWP solutions, making them the ideal choice for those who need to prepare for the new equipment that will be required as of January 2026, said Jason Chong, marketing manager – North America at Tecumseh.

“In 2020, Tecumseh was the first manufacturer of reciprocating compressors to adopt A2L refrigerants for commercial refrigeration,” he said. “Since then, Tecumseh has continued to increase its offerings.

Some of those offerings were introduced at the AHR Expo, such as the RG and HG compressor Series, which utilize A2Ls. Currently compatible with R-454B refrigerant, they are also under development for use with R-32 in the near future. These compressors are designed for use with heat pumps, water heaters, and air conditioning applications and are now available for customer sampling in the North American market, said Chong.

A2L READY: Jason Chong stands aside Tecumseh compressors, which utilize the A2L, R-454B. (Staff photo)

“Aside from the reliability and efficiency that Tecumseh’s compressors are known for, these compressors offer versatile mounting options. For example, the RG and HG are traditional vertical form and horizontal low-profile platform compressors, making them ideal for modern heat pump and air conditioning requirements,” said Chong. “It is also worth noting that Tecumseh is the only manufacturer that produces these types of rotary compressors in the western hemisphere. As the supply chain risks from the Asian region remain, the demand from a number of global OEM customers is increasing.”

One of the biggest trends right now is a shift to heat pumps, which have become increasingly popular. Tecumseh has served climate control and heat pump applications for decades, and its rotary compressor technology is getting significant attention in the market, said Chong.

“In addition to the conventional alternate current compressors such as the RG and HG, Tecumseh offers variable-speed, direct current (DC)-powered compressors to meet the demands of innovative heat pump technology,” he said. “Traditionally, DC-based cooling was used in automotive cabin cooling, especially for no-idle applications. In fact, our DC compressors are used in EV cooling applications, and the same technology has increasingly become relevant in heat pumps, chillers, solar, and various forms of commercial cooling applications. Tecumseh’s DC specialist division — Masterflux — has an innovative lineup of compressors and systems, with multi-voltage options, and multi-refrigerant offerings, including R-290.”

Chong noted that 2024 will be a year with continued changes in the industry, with policy and regulation changes rapidly pushing the market towards low-GWP offerings.

“Tecumseh has the widest offerings of compressors and value-added systems, which are ready to help our customers make their transitions.”

general manager

Carlyle Compressor

Alternative Solutions

Carlyle Compressor introduced a full line of CO2 compressors at the AHR Expo, including rotating and reciprocating compression technologies available in fixed- and variable-speed configurations. The latest CO2 product line complements Carlyle’s existing CO2 06V product, said Joel Moseley, general manager of Carlyle Compressor.

NATURAL SOLUTION: Carlyle displayed its CO2 compressors at the AHR Expo, including rotating and reciprocating compression technologies, which are shown here with Joel Moseley. (Staff photo)

“Carlyle is providing alternative compression solutions in support of global regulatory requirements for the application of low-GWP and natural refrigerant solutions, while also contributing to the industry’s effort to improve system energy efficiency,” said Moseley. “In states like California with regulatory requirements, these new units provide end users and contractors with alternate solutions to meet the new requirements.”

The 06V product has an expanded low- and medium-temperature operating envelope, making it an excellent fit for single compressor CO2 sub/transcritical condensing units, said Moseley. Carlyle is also introducing CO2 rotary compression technology to North America this year through its Toshiba Carrier line.

Carlyle also reintroduced its familiar 5H compressors. The newly tooled products include an enhanced bearing design and upgraded capacity modulation technology, and in 2024, the ammonia 5H product line will be expanded to include the largest displacement, said Moseley.

“There is an across-the-globe engineering effort to move to lower-GWP refrigerants, including HFOs and increasingly, natural refrigerants,” said Moseley. “Carlyle will release several new products in 2024 in support of our customer’s needs for expanded system flexibility and alternate compression solutions.”

Report Abusive Comment