Global demand for comfort cooling is growing, which is contributing to increased carbon emissions and putting a strain on electricity grids around the world and in the U.S. In fact, according to a report from the International Energy Agency (IEA), global energy demand from air conditioners is expected to triple by 2050, with the global stock of air conditioners in buildings growing to 5.6 billion by 2050, up from 1.6 billion today. That amounts to 10 new air conditioners sold every second for the next 30 years, according to the report.

This is a concern, as HVAC systems, as well as commercial refrigeration equipment, consume a significant amount of energy, which leads to increased carbon emissions. To address this problem, manufacturers have been working hard to find solutions, with one of the most promising being the variable-speed compressor.

Fixed vs. Variable

Director of product management of Turbocor® Compressors, Danfoss

Unlike traditional fixed-speed HVAC systems, which are designed to meet peak load requirements on the hottest or coldest days, variable-speed compressors offer a more energy-efficient solution. Using this technology, HVAC systems can adjust their output to precisely meet the specific demands of the building, the local climate, and even to balance loads across multiple compressors or systems, said Frank Ford, director of product management of Turbocor Compressors at Danfoss.

“By doing so, variable-speed compressor systems can deliver energy savings of up to 40% compared to fixed-speed compressor systems,” he said. “This significant reduction in energy usage not only yields cost savings for building owners but also contributes to decarbonization efforts by reducing the need for additional power plants.”

As conventional fixed-speed systems are typically designed to accommodate peak load days, they usually have more capacity than is required for normal everyday usage. Consequently, these systems frequently turn on and off, which can lead to fluctuations in temperature and reduced humidity control, as well as decreases in efficiency due to the starting and stopping, said Vickie Blakey, residential product marketing manager at Emerson.

“Modulating compressors, on the other hand, give systems the ability to adjust capacity to match the load, and this results in longer run times at higher efficiency to maximize both comfort and energy savings,” she said. “The use of modulating compressors in heat pump applications assists with building decarbonization goals for heating and cooling by helping to reduce emissions, as well as energy consumption.”

HVAC OPTIONS: Variable-speed compressors are often used in heat pumps, rooftop units, chillers, and geothermal systems. (Courtesy of LG Electronics Component Solution)

Heat pumps are also increasingly replacing or supplementing fossil fuel-based heating equipment like boilers and furnaces, which can further reduce a building's carbon emissions. Variable-speed heat pumps specifically aim to address space heating needs by offering additional capacity during extremely cold weather conditions when the outdoor temperature falls below freezing, said Jerry Edwards, part leader of sales engineering at LG Electronics Component Solution Business Team.

“Fixed-speed technology cannot adjust, so when the components are sized for high-temperature cooling, they are effectively undersized for low-temperature heating,” he said. “Variable-speed technology allows the ability to compensate on both ends of the spectrum, by reducing compressor output when it's not necessary and increasing it when it is required.”

Applications

Variable-speed compressors can be used in a wide range of HVAC equipment, including heat pumps, rooftop units, chillers, and geothermal systems, but the benefits of the technology will vary depending on the application. As Edwards noted, variable-speed technology makes the most sense in systems that are designed to operate across a wide range of compressor loads and desired output capacities.

“Variable capacity brings higher efficiencies, potentially higher capacities, and lower sound levels when the technology is what the system needs,” he said. “If the system operates at a fairly small range of loads/outputs, a variable-speed compressor would not be needed and would not bring a considerable advantage. It also might be too expensive to use in very large systems, but for residential heat pumps, rooftops, and the like, there could be benefits to utilizing variable-speed technology.”

Variable-speed compressor systems also generally cost more than their fixed-speed counterparts, but as they offer higher energy efficiency, they will provide a lower total cost of ownership when considering the long-term energy cost savings, said Ford.

“To maximize the cost savings, varying load conditions are necessary, and the more the conditions vary, the more the benefit,” he said. “While these varying load conditions are typically present in most buildings, there are certain applications which have more consistent load requirements, so the use of variable-speed compressor technology may result in longer payback times.”

In some cases, variable-speed compressors can be retrofitted into existing HVAC systems to improve energy efficiency. However, it would be more advantageous to install a new system with variable-speed compressors, said Blakey, as it would generally be more efficient and have lower carbon emissions than an existing system with a variable-speed retrofit.

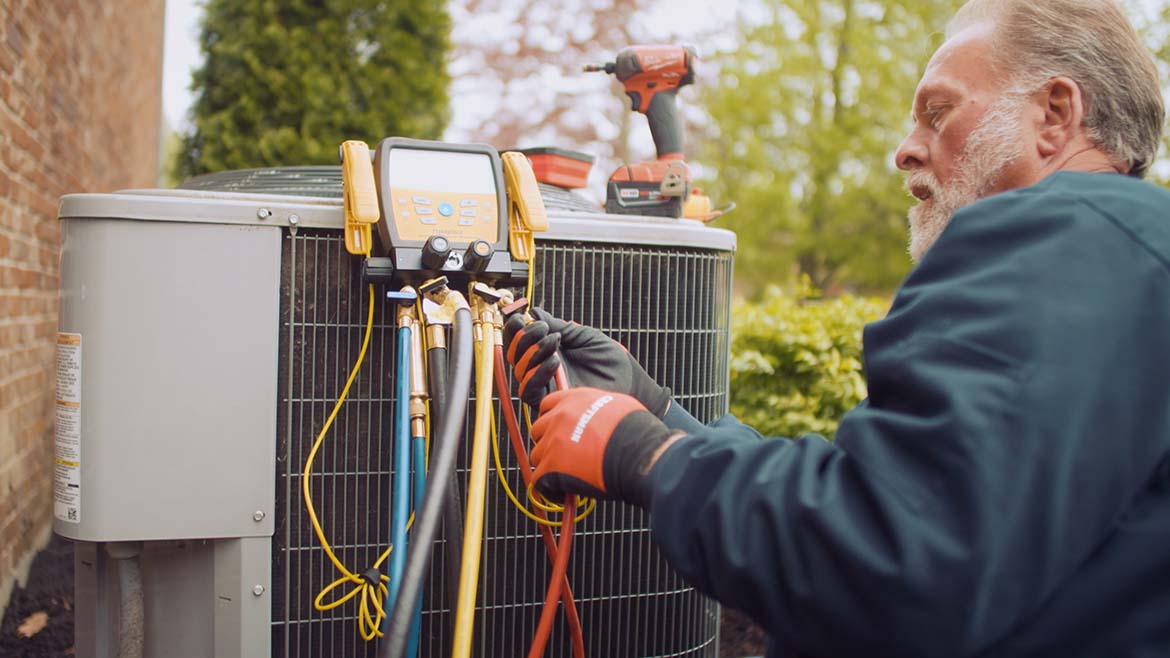

IMPROVED EFFICIENCY: In some cases, variable-speed compressors can be retrofitted into existing HVAC systems to improve energy efficiency. (Courtesy of Emerson)

When retrofitting a system with variable-speed compressors, the primary consideration is the compressor control, said Ford. That’s because, unlike fixed-speed compressors that operate on an on-off basis, variable-speed compressors require a signal or program to control their speed through a VFD or built-in compressor controller.

“It's also important to note that not all types of variable-speed compressor technologies are suitable for retrofitting,” said Ford. “For instance, oil-free compressor technology pioneered by Danfoss with the Turbocor compressors is not recommended for retrofit due to the challenges in fully removing the oil from the system. Leaving oil in the system can cause harm to these types of compressors.”

NO RETROFIT: Retrofitting oil-free Turbocor compressors into an existing system is not recommended due to the challenges of fully removing the oil from the system. (Courtesy of Danfoss)

Benefits

In addition to saving energy, variable-speed compressors can help improve IAQ and comfort by allowing longer run cycles of the HVAC equipment, which will reduce relative humidity and temperature fluctuations, making the space inherently more comfortable, said Blakey.

“The quick pull down of room temperature and swift adjustment to demands are key factors for customer comfort,” she said. “For example, scroll compressors with continuous modulation can adjust from 10% to 100% capacity (or vice versa) instantaneously by varying the relative durations of loaded and unloaded cycle times. This means reacting to changes in system demand much faster, without having to pass through intermediate speed changes. Modulating scroll compressors that utilize digital technology also feature enhanced controls and protection along with tighter humidity control.”

Variable-speed systems essentially match their output to the demand of the conditioned space, which leads to a tighter control of indoor temperature, said Edwards. In addition, variable-speed systems can be designed to operate specifically for dehumidification, which can be a key variable in defining the comfort of an indoor space.

“Dehumidification requires adjusting the compressor speed and the indoor airflow to primarily remove humidity instead of primarily cooling the space, which fixed-speed systems cannot do,” he said. “A fixed-speed system provides dehumidification as a side effect of cooling the space, and when the ambient conditions are mild, the dehumidification can virtually be negligible. A variable-speed system can bring marked improvement in those milder climates.”

Another benefit is longevity. Traditional fixed-speed compressor technologies that cycle on and off frequently can experience excessive wear and tear on their components. This is especially true for oil-based compressors, said Ford.

“By reducing the number of start and stops, variable-speed systems can help extend the life of the compressor and other components, which saves building owners and end users money on maintenance and replacement costs,” he said.

Edwards added that sound levels are also lower with variable-speed systems, as most of the indoor and outdoor components, including compressors, motors, and fans, are quieter when operated at lower speeds.

Refrigeration

Variable-speed compressors are also used in commercial refrigeration applications, where they can effectively tackle two critical components of sustainability: energy efficiency and the transition to lower-GWP refrigerants, said Joe Summers, senior product manager of scrolls and drives for Emerson’s Climate Technologies Business.

“Compared to fixed-speed compressors, variable-speed compression technology typically delivers 20% to 30% energy-efficiency improvements in refrigeration applications,” he said. “Variable-speed compressors are also being qualified for use with lower-GWP refrigerant alternatives, such as CO2, R-290, and emerging A2L refrigerants. Because variable-speed compressors can run at twice the speed of their fixed-speed counterparts — thereby doubling refrigerant mass flow — they can produce up to two times the compressor cooling capacity using smaller charges of lower-GWP alternatives. This means that one low-charge R-290 or A2L variable-speed compressor could potentially deliver the same capacity as two fixed-speed models, eliminating the need for multiple refrigeration circuits in some instances and, in turn, reducing applied costs and equipment footprints.”

Incorporating variable-speed technology in commercial refrigeration systems offers other advantages as well, said Summers, such as reducing compressor cycling by up to 90% when compared to fixed-speed models; eliminating excessive wear and tear on the compressor; lowering maintenance expenses; prolonging the lifespan of the equipment; and operating more quietly.

“The goal of variable-speed compressors is to run at the lowest speed possible for the longest duration possible. One of the operational benefits of this is the improvement in sound quality and compressor harmonics,” he said. “Not only does the continual low-speed operation run quieter than a single-speed fixed compressor, but the sounds of Copeland compressor cycling are replaced with a consistent hum that becomes nearly imperceptible white noise.”

Variable-speed compressors enable precise load matching and improved temperature control and can be used in a wide range of low- and medium-temperature commercial refrigeration applications, including self-contained, reach-in units; remote condensing units; distributed scroll packs; and rack retrofits. They can also be used in both new and retrofit applications, however, Summers cautions that there are retrofit situations where an undersized compressor may never be able to run at part-load capacity (i.e., any capacity other than full), which would defeat the purpose of using variable-speed technology.

When it makes sense, however, retrofitting a variable-speed compressor into an existing fixed-speed compressor rack can be an effective way of enabling variable-capacity modulation, said Summers. He said this strategy involves replacing an aging compressor with a variable-speed compressor to serve as the lead compressor in the rack.

“It’s also possible to simply apply a VFD to a fixed-speed compressor and either configure it to run off the compressor’s suction pressure or tie it into a refrigeration system control,” he said. “The E3 supervisory control from Emerson, for example, has native programming to support these types of installations, and even legacy controllers such as the E2 control can easily be updated with the information required to maximize the benefit of a variable-speed compressor in a retrofit scenario.”

With an increasing number of end users focused on achieving sustainability and decarbonization goals, the need for energy-efficient mechanical systems will only continue to rise. Variable-speed technology provides a viable solution to this challenge by allowing HVACR equipment to operate more efficiently and precisely, resulting in reduced energy consumption and lower carbon emissions. As a result, the future of HVACR equipment appears to be increasingly tied to variable-speed technology.

Report Abusive Comment