Can the type of ultraviolet light known as UV-C light kill the novel coronavirus?

Manufacturers are not making that claim … yet. UV-C has a proven track record of neutralizing a range of microorganisms. The real question is probably not whether this light can kill this coronavirus as much as when the HVAC industry will get a more precise idea of exactly how.

Carla Cantor recently wrote an article on Columbia University’s website about the university’s research. She reported that ultraviolet light, already having demonstrated effectiveness in killing two coronaviruses that inflict less severe symptoms on humans, is now undergoing testing against the novel coronavirus “with encouraging results.”

DeZiel Heating & AC in Buffalo, Minnesota, tells website visitors that “we presently don’t know specifically the UV-C dose necessary to kill this new novel coronavirus, yet viruses are some of the easiest micro-organisms to kill.”

DeZiel continues that testing will determine the dose of UV-C required to kill the virus, but even short of a firm kill rate, UV-C “will also disrupt its DNA, sterilizing it and rendering the virus harmless even at lower UV-C dosages.”

ASHRAE presently maintains a broader stance regarding the type of light as a disease-fighter, issuing guidance recommending UV-C as a strategy whether it is deployed via upper-room, in-room, or in-airstream equipment.

This unusual set of circumstances presents a rare opportunity with a less-daunting learning curve to HVAC contractors who have already extolled (and installed) in-duct UV-C lighting for its ability to keep coils — and the air that passes by them — clean.

Spike in Ultraviolet Interest

“No question that COVID-19 bumped up interest levels for UV lights,” said Steve Lauten. Lauten is president and CEO of Total Air & Heat, which has installed UV-C equipment in residential and commercial settings.

Lauten said the surge was such that the company lost a little business due to backorders on ultraviolet equipment. With items back in stock now, “we are seeing an increase in UV light sales along with overall sales.”

Aaron Engel, vice president for business development at Fresh-Air UV, noted that over the last 20 years, in-duct UV-C systems have typically served to (among other things) disinfect coils and provide associated efficiency and maintenance benefits.

“COVID-19 changed the rules,” Engel said. The coil-related benefits remain, but in his experience, consumer interest changed not only in volume but in degree of urgency. Now, as some areas begin to step around the corner and into a post-lockdown environment, he sees commercial interest tipping upward.

“As facilities are beginning to reopen, many companies are looking to add UV technology to help address concerns over air quality, reassuring building occupants they are doing the most they can to ensure safety in the workplace,” Engel said.

With interest blooming on the consumer side, one might wonder if UV-C equipment might grow from a relatively familiar add-on to more of a presence in original designs and installations.

Engel, for one, does expect to see more collaborations in this area, especially in the current environment.

“There is no question UV-C manufacturers can find partners within the industry to offer products to the market that provide comfort and security.”

Director, airside sales and marketing UltraViolet Devices Inc.

Encountering UV-C as an Add-On

With many owners already familiar with UV-C as a part of their existing systems, some might naturally wonder if what they have already will suffice to battle a new threat in terms of COVID-19.

That answer will vary from case to case, of course, based on the specs of the current installation and the findings of research into the coronavirus and effective kill rates.

Systems selected and assembled specifically for more traditional coil- and air handler-related purposes may need some augmentation to serve an expanded purpose.

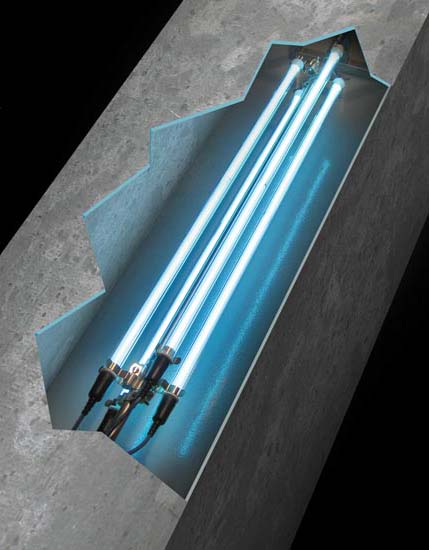

IAQ ATTRACTION: Contractors can use mounting clips if an existing grid system is in place, said David Heidel of UltraViolet Devices Inc. If not, other options include direct mounting to an air handler or using magnetic mounts for lights inside ductwork. This image models what UVDI’s V-MAX product would look like in place. PHOTO COURTESY OF ULTRAVIOLET DEVICES INC.

“Because achieving airstream disinfection simply involves increasing the dosage of UV-C, many are able to use the existing framework that has been installed for coil cleaning, and simply add more rows of UV-C lamps in order to achieve their airstream disinfection targets,” said David Heidel, director, airside sales and marketing for UltraViolet Devices Inc. (UVDI).

Heidel said UVDI has been working with many owners to add ballast and lamps to a previously purchased UVDI scalable product that was originally intended to clean coils, eliminate odors, or reduce volatile organic compounds.

Heidel cited installation options for contractors, including mounting with clips inserted into an existing scalable grid system, direct-mounting to the air handler, or using magnetic mounts to add lights in ductwork.

Engel outlined variables that must play into a proper design for fighting microorganisms.

“These include dosage requirements of the pathogen, dwell time, intensity, and air recirculation rates,” he said.

Knowing that recirculation rate is a key for contractors, Engel emphasized. He used an example of a hospital operating room with no recirculation at all, versus a school space with six air changes per hour.

“As air recirculates within a home or building with every pass by the UV fixtures, more of what is in the air will be disinfected,” he said. “Airborne pathogens that may not have received the lethal UV dosage on the first pass may receive the lethal dose on the subsequent pass by the UV system.”

Engel said that contractors should expect UV manufacturers to be able to provide disinfection reports based on this range of variables, which contractors could offer as needed to the end user even before the system is installed.

The relationship between the objective and system particulars only reinforces that this is not a one-size-fits all situation.

“Coil disinfection, which is the most common type of application, requires less UV energy because there is enough time for the UV-C light to irradiate the stationary coil” and other nearby surfaces, Engel said.

Microorganisms like the coronavirus, far from a sitting target like the coil, will provide a more fleeting opportunity requiring an increased UV-C dosage in the vicinity.

While existing systems designed to keep coils clean may require additional lamps to expand the mission into killing viruses, UVDI’s Heidel explained how all of this can also provide a stroke of good fortune for new construction owners or existing properties installing UV-C for the first time.

“When UV-C systems are sized appropriately for airstream disinfection and installed directly downstream of the coil, the benefits of coil cleaning will be delivered at the same time that airstream disinfection is being achieved.”

Getting Up To Speed in UV-C Technology

“The best installation is the informed installation,” Heidel summed up. A truly comprehensive assessment requires even more information, such as the details of the air handler, duct dimensions, and materials in the space. These, he outlined, can affect UV-C reflectivity.

Contractors should look to the manufacturer (and distributor, presumably) to navigate a project successfully. Some factors would be easy to overlook without experience.

“Being aware of components within close proximity of the UV-C that may be sensitive to UV-C degradation” is one example. In a situation like that, solutions like strategically-mounted foil tapes or deflectors are not difficult but can make a real difference.

Engel concurs that the proper system will deliver results that will complement conventional filtration, tailoring the investment to the case.

“Not every facility or home needs a one-pass 99.9 percent airborne inactivation rate. The contractor, with help from the UV manufacturer, should evaluate the needs of the customer and offer the right solution.”

Heidel pointed out another byproduct of any increase in the adoption of well-done UV-C systems: More contractors will benefit from cleaner working environments and the security of knowing the space has been decontaminated, improving their own safety.

(He added one caveat: Coordination between electrical, controls, and mechanical contractors is needed to establish a proper safety mechanism for contractors entering the space. Heidel said this will ensure disconnection of power when access doors are opened, preventing UV-C direct exposure to human eyes or skin.)

Total Air & Heat’s Lauten relays that his company considers whole-house filtration solutions as “must have’s” with UV-C being the “next step up.”

Lauten observed that while UV-C may not be marketed as a COVID killer yet, the technology is touted against the flu and other airborne illnesses. That option exists alongside, not in place of, what assorted vaccines or treatments can offer.

With COVID-19 likely to survive to some degree beyond the advent of any vaccine, “I feel COVID-19 will be around a while longer,” he said. That likelihood, in Lauten’s opinion, will continue to translate to an opportunity to offer system enhancements.

In the meantime, people are looking for ways to be smart — and minimize a feeling of helplessness — about disease in ways that also won’t upend life as they have known it. Fresh-Aire UV’s Engel sees that as one more potential ace up the technology’s sleeve for helping people through this period.

“Taking control of the air we are breathing,” he said, “can be one of the most empowering things we can do right now.”

Don’t Get the Wrong Bright Idea

ENLIGHTENING INFO: LED notifications, e-alerts, building management system integration, and mounted radiometers can all assist in proper maintenance regimens for installations like this airstream disinfection system. PHOTO COURTESY OF FRESH-AIRE UV

The bulbs don’t last forever. Like most things in life, a UV-C bulb’s microorganism-killing qualities eventually wear out.

The idea of replacement and maintenance, a concept that homeowners and contractors alike generally accept, runs into a couple of hurdles when it comes to UV-C installations.

Unlike the ones in the den or the kitchen, these bulbs are out of sight and thus largely out of mind for the occupant. The effective lifespan of a common bulb in these applications can range from around a year to two years.

Those fairly clean intervals can help contractors turn this hurdle into a little more business.

“My experience is homeowners rarely service UV light systems and leave it up to us,” Steve Lauten of Total Air & Heat said.

“Many of the UV light systems we offer have bulbs good for two years, and we simply include bulb replacement as part of the preventive maintenance services we offer.”

Fresh-Aire UV’s Aaron Engel brought up what may be a more surprising fact for many customers and some contractors.

“The UV lamp will ‘shine’ for years, but the UV effectiveness, which is unrelated to the visible light emitted from the lamp, has diminished to the point of ineffectiveness.”

That’s right — unlike every other light in the building, a UV-C light may essentially be off while it’s on.

Engel lists LED notifications, e-alerts, and building management system integration as notification methods that can overcome this peculiarity. He also expects that installers that may have been more complacent regarding UV lamp replacements will start to do a better job educating their customers about this sort of thing.

Some companies such as UVDI offer a fixed radiometer, UVDI’s Heidel said.

This “can be mounted directly across from the installed UV-C lamps after a roughly 100-hour ‘burn-in’ period and will indicate when the lamps are no longer operating at their designed [effectiveness].” The radiometer’s signal can translate to blinking lights or transmit to building automation.

He encouraged contractors to use these tools and to make “neither the assumption that it is ‘safe’ to be exposed to UV-C lamps or that the UV-C lamps are still generating a sufficient amount” of light to properly disinfect.

UV-C maintenance is critical, he said, much as “filter changes and routine coil cleaning have been important for as long as HVAC systems have existed.”

Contractors just have to know when to change the bulb — and to remember this is one change-out that has to be done with the lights off.

Report Abusive Comment