Modern distributors face a barrage of change on multiple fronts. Refrigerant evolution, technology that presents both opportunities in settings like the warehouse and competition from beyond, shifting customer needs and expectations … it all blends into a challenge to adapt while remaining a familiar and valuable connection for the contractor.

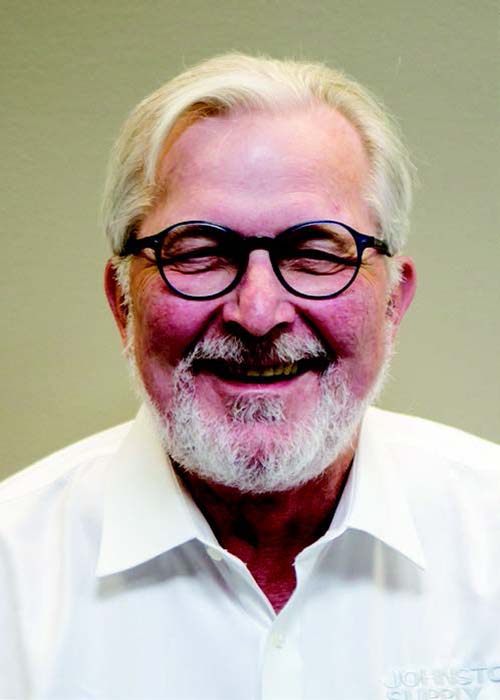

This year’s roundtable participants from around the U.S. and Canada have each tried different solutions and found different paths to success. They are:

Their comments reveal shared themes and individual tactics in this year’s roundtable conversation.

What’s a change your company made in the last year or so to become easier to do business with? Big or small, doesn’t matter.

Hooper: We did a personality assessment of our people, everyone in our organization. This gave me, as the leader, some unbelievable insight into the nature and fundamental flow of each person in our business. Seeing as how our people are the most important and impactful asset, this allowed me to really drill down on the forward-facing customer experience, making sure we had the right people in the right positions for our customers.

Boutette: Over the last year or two, we have implemented a new website and an e-commerce platform to make it easier for customers to check stock, confirm pricing, and place orders electronically from their office computer or remote app.

We have also enhanced our ability to cross-reference a multitude of OEM [original equipment manufacturer] part numbers to our part number. We continue to strive to make it easy to do business by providing easy access to information.

McIlwaine: We continue to invest in our HVAC MobileSales mobile app and our Web Order Entry product to improve the breadth and depth of information. In addition, our company utilizes Lean (continuous improvement) events (kaizens) to identify areas of our business that are not as effective as they can be. These areas might be customer-facing external processes or internal processes that inhibit maximum effectiveness and user-friendliness of the process.

Distributors can find themselves caught between the way manufacturers might naturally think of training (ahead of time, more often in person) and the way contractors often want information (on demand when they need it, more often in the field). How are your training offerings developing?

McIlwaine: Our training team is very flexible and is effective at utilizing Zoom to do remote meetings, or will do it in one of our facilities or at a contractor’s facility. Most of the Zoom meetings are recorded and made available for our customers or staff to view on demand.

We have found that our customers do not want to invest full days on trainings, so we have condensed many of the training topics so we can do two-hour training sessions.

Hooper: In our local market, we have taken the lead on being the training magnet for the contractor. We offer weekly training, every Wednesday, and focus on not only the technical side of the business but also on the basic business acumen needed to ensure our customers are profitable and have the know-how to measure/track their profitability.

We have partnered with industry leaders and third-party trainers who help focus on the critical contractor needs as well. Those critical pieces are consistently centered around the people who answer the phone for the contractor and the people being dispatched to the work or in the home.

Roberts: We are in the process of launching a new LMS to offer more on-demand training of all types in the next few months and have partnered with our major manufacturers to give our contractor customers access to shorter, on-demand training classes and videos in the near term.

Would you ever consider investing in an app for your customers? What would be in one, if you could snap your fingers and have it finished?

Roberts: We launched a contractor-facing mobile app in 2011 to put more helpful information in the palm of technicians, as well as to allow them access to quicker technical support, order placement, and special product discounts.

Hooper: Absolutely. Anything that improves the customer experience would be a wise investment. More specifically, an app that helped our contractors perform a Manual J load calculation on-site, that could ensure proper equipment sizing before quoting, would be a valuable and necessary investment.

McIlwaine: We did it a number of years ago, and sales on our app continue to grow every year.

Alan Beaulieu at ITR Economics has talked about a “basset hound” being something that a business does that it should stop doing. Is there an offering or resource or practice that your business discontinued in order to get stronger by subtraction?

Roberts: One of the things we have considered doing is going completely paperless and thus eliminating mailed documents and materials. We have found that this idea works for a lot of customers but not quite all of them, so we are still in transition mode there.

McIlwaine: Through our continuous improvement process, we have streamlined processes and eliminated many reports and activities that were not bringing value. This has allowed us to look to technology and automation for improvement.

Extended warranty invoicing used to take about 25 hours per week. After a kaizen event and some cooperation between Goodman’s tech people and our technology folks, it is now two to three hours. There are many other examples.

Boutette: Also, as businesses grow and change, some positions may change. We like the analogy of having people on our bus. When a person is hired, they are assigned to a seat on the bus. Over time, the seat might change and the person no longer fits the seat, or the seat is no longer used. In this case, management must decide the right seats for the right people. Things don’t always stay the same.

What changes has your company seen over the last year with regard to the threat of online sales to revenue and customer relationships? Meaningful in your area? Any trends?

Hooper: The online sales threats are real. Amazon is becoming more sourced in our trade by the contractor base, especially from a tooling perspective. This is certainly decentralizing the customer experience to a degree and driving decisions for some of the customer base.

We launched our e-commerce site for our customers, with great success and feedback from each customer who is currently using that platform.

Boutette: It is a reality that there is consumer demand for this. It is a threat. There are some things to consider.

When the consumer buys something online, they need to know what they are ordering. How do they know if they need a capacitor, a motor, or a relay to fix their a/c unit? How do they install it? There are still barriers to this market and services that can only be provided by a certified and qualified technician. In Canada, we have trade license requirements to work on equipment.

As distributors, our challenge is to replicate the kind of service that can be experienced with online ordering. So we need to offer an online presence where a certified contractor with an account can check stock availability, get their pricing, place an order, specify when and where they want the order sent, and expect that all to happen.

McIlwaine: The products that have dollar density (lightweight, small, and cheap to ship) are the most at-risk products, so we pay close attention to them. We are watching the trend but have not seen significant inroads, especially on the equipment side.

Automation, virtual reality, wearables, tracking technology, A2L refrigerants ... these and more are knocking on warehouse and operations doors. How different does your warehouse look from three years ago? How different do you think it might look three years from now?

McIlwaine: We have been barcoding since 2001, and we utilize that in all our branches and CDCs, so we were ahead of the curve regarding that technology. We are looking at wearables, but with our current distribution center constraints, automation is not possible. I am very concerned about the A2L’s and the implications to our industry. The flammability potential will probably impact our insurance for both our warehouses and our trucks.

Roberts: At this point, we are on the verge of transitioning toward implementation of warehouse and automation technologies, so while it looks similar to three years ago right now, it will look drastically different in three more years.

Boutette: Over the past few years, our warehouse has become much more efficient. We have moved from “milk runs” with specific routes on specific days and delivery once or twice a week to daily delivery, overnight delivery, direct-to-job delivery, and emergency direct one- to two-hour delivery and customer rush pickups. This requires a warehouse that is not only efficient but agile. Warehouse design, zone picking, and RF scanners are just a few elements we have implemented.

In the future, we will have to improve inventory accuracy and quicker picking methods using more robotics and efficient computer technology. Maybe even drones!

Share a trend that you would advise other distributors to start getting ahead of (or catching up to) now.

McIlwaine: A2Ls are a real concern for 2023 and beyond. With the potential of the OEM manufacturers having several different refrigerants, our customers could have to service four or five different refrigerants in residential equipment. I think the complexity will have a very negative affect.

On top of the refrigerant change, efficiency minimums are increasing, and we are getting to the point now that the move from 13 to 14 in our Northern Region, and 14 to 15 will not only have a higher price, but payback will not be there in most residential instances. 2023 contains lots of risks for our industry.

Hooper: The price pressure and decentralized customer trend driven by Amazon. Also, the rapid consolidation from manufacturers, which is reducing the number of options we have as distributors to source products. I don’t see anything slowing or stopping this trend.

I imagine there will be a time in the future where the products we buy can all be sourced online, maybe even for next-day delivery, and only from one or two manufacturers. This, as you would see, could be a big threat to distribution. I would encourage any distributor in any segment to look at what their value proposition to the customer base looks like in that scenario, and how they plan to stay profitable when facing that environment.

Roberts: I think there will be a strong upward trend in the use of artificial intelligence and virtual reality in the next five years that will drastically transform the in-store and online shopping experiences as well as training. It’s an exciting time for technological advancements in our industry.

Boutette: I would say the biggest trend distributors need to catch up is technology. E-commerce and B2B solutions are here, and we need to invest to keep ahead of this changing business tool. It is neverending.

We cannot stand still when it comes to technology; we must continue to re-invest. This should be a top priority. I think if a distributor has not started down this path of embracing technology, it may already be too late.

See more articles from this issue here!

Report Abusive Comment