The outside temperature was 40°F, not really cold for the season but the humidity was high in the air. Moisture had just seemed to be laying in the air for several days.

Bob and Tim were called to a residence which reported a frozen heat pump. They arrived and talked to the housewife and she said, “My heat pump outdoor unit is a solid block of ice. When I look at my neighbors outdoor heat pumps they don’t look like mine. I think something is not right."

They all went to the window in the dining room and looked down on the heat pump outdoor unit and sure enough it was loaded up with ice.

Bob said, “you’re right, it is 40° outside but the heat pump coil outside has to be much colder than 40° to remove heat from the air. It operates well below freezing but has a defrost cycle to keep the ice from building up on the coils. It is obvious that this unit has a problem and it has been compounded by the high humidity that we’ve had for several days. Heat pumps will normally gather much more ice in very humid weather like we’ve been having and sometimes the defrost cycle will just not take care of it. We will go out and get into the problem. We must first get all the ice off of the coil before we can do any troubleshooting."

As they were going outside Tim asked, “what is the plan, what do we do first?"

Bob said, “most technicians would force the unit through several defrost cycles to remove the ice from the coil. This probably would work and it may take a lot of extra time forcing defrost cycles that may not defrost the ice. If the unit is low on refrigerant, there may not be enough refrigerant for the defrost cycle to be 100 percent effective. I would prefer using a water hose on the unit to remove the ice. Then get into the analytical side and find out why it has accumulated so much ice on it. If a unit is low on refrigerant the defrost cycle may not totally defrost and then the next cycle will build more frost which will not defrost during the defrost cycle and this will go on and on until the coil is a solid bank of ice, like this one. Let’s go to the truck and get a water hose that we know is good and not frozen full of water. It was 20° last night and if we had a hose full of water it would be solid. That is why each time I drain the hose after use."

Tim went to the truck and got the water hose and they connected it to a close by hose bib. Bob then instructed Tim to turn off the power to the unit and remove the top of the unit so that they could get water to the inside of the coil as well as the outside. He also instructed Tim not to allow water to flow on the control panel. They covered the control panel with a piece of plastic to shield it from water. Then they started hosing the coil with water from the house which had a temperature of about 45°. Water in the main in this part of the country would typically be about 45° in the winter.

Bob explained to Tim, “this is not solid block ice like an ice cube which would take a long time to defrost. This is what I would call aeriated ice, it has a lot of air in it because of the way it was developed on the coil and it will defrost very quickly. If you have ever had flake ice in a cold drink versus an ice cube, you probably noticed that flake ice defrosts very quickly where an ice cube lasts a long time. It’s the same concept."

When they had all of the ice off of the coil, they started the unit operating. Bob said, “the coil is wet with water and while it is operating let’s see what kind of ice pattern forms on the coil. I would prefer not to install gauges to prevent altering the charge. Let’s operate the unit and see if we believe the coil is full of refrigerant and if we believe it is, we will declare that the unit does not need refrigerant and move to the electronic circuit and check on the defrost cycle. It won’t take long for this unit to start building ice and we can check the liquid level in the coil without putting on the gauges."

After about 20 minutes of operation they could see the coil frosting from top to bottom which indicated that there was plenty of refrigerant in the unit. They let it continue to operate for a while and then they forced a defrost, the unit went into defrost but only stayed there about 30 seconds and went back to normal operation in the heating cycle.

Bob said, “That’s a sign that the defrost cycle is not functioning correctly. I’m going to suggest that we change the circuit board that controls the defrost cycle and try the operation with the new board."

They changed the circuit board and started the unit back into operation and operated it for about 20 minutes and forced another defrost cycle. The unit ran until the coil was completely defrosted and switched back over to heating again.

Bob said, “I am going to declare this unit fixed. The defrost cycle is acting normal and should continue to act normal and the coil should stay defrosted through all types of weather."

They described to the homeowner the repair that they had made and told her to keep an eye on the unit for a few days to make sure that it was operating correctly. Then they moved on to the next job.

As they were leaving, Tim asked Bob to explain the defrost cycle to him. He had studied the defrost cycle in school but had never been on the job and seen a system that was not functioning correctly.

Bob explained, “The outdoor coil operates as an evaporator during the winter cycle with the condenser being the indoor coil. The outdoor coil absorbs heat by operating below outdoor temperature. Therefore, during a normal cycle frost will gather on the outdoor coil. When the outdoor humidity is operating below normal it will gather an abnormal amount of moisture or ice on the coil in the form of frost, not ice. Defrost cycles are typically set up to occur every 30 minutes 60 minutes or 90 minutes, depending on the location. If the location is a very moist location, such as a lake front property, a 30 minute defrost might be in order. This means that the unit will go into a defrost cycle every 30 minutes."

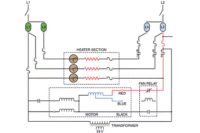

The unit is operating in the air-conditioning cycle during the defrost cycle and is not efficient at that time as it is removing heat from the house and using that heat to defrost the outdoor court. At this time typically the strip heat comes on to keep the house from getting cool from the cold air exhausting from the unit. This normally only happens for a very few minutes until the defrost is terminated. Defrost termination is normally accomplished with a small thermostat located somewhere on the coil or the liquid line leaving the coil that verifies the refrigerant in the coil is well above freezing, 50° is fairly typical of the setting on this thermostat. (Figure 1) When the unit goes into defrost the hot gas moves into the condenser and defrosts the frost on the outside by heating it from the inside with hot gas. The unit is then acting just like an air-conditioning condenser for the duration of the defrost cycle. When it is detected that the coil is warm enough to verify it is ice free, the unit will switch back to heating and the outdoor coil will then be an evaporator again. Remember all of this is accomplished with a heat pump reversing valve located in the heat pump unit (Figure 2)."

Tim said, “I think I have it now. It seems like you understand it in the classroom and in the lab at school but when you’re outside and it’s cold and things are happening quickly, it’s hard to remember your good lessons that you had been taught."

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment