Bob and Tim are at a new customer’s job site. It’s an older, free-standing restaurant, and the complaint is that the ductwork is dripping water into the customers’ food. They enter the back door through the kitchen and find the owner. He explains to them that the ductwork runs through the area where the customers eat, and the dripping is falling on the customers and in their food. This is not satisfactory, and something has to be done.

“You have a 20-ton unit that serves the entire restaurant. Is all of the other equipment working correctly?” Bob asked

The owner then explained that the exhaust fan in the kitchen is not working, and the kitchen is very hot.

Bob and Tim did a walk-through of the entire restaurant, looking to see if they noticed anything different. Then they went to the roof where the 20-ton rooftop unit was located. It was a 90°F day, and the humidity was very high. Tim commented that the air coming out of the top of the condenser was very hot.

Bob told Tim to go to the truck for get gauges and a temperature tester. “We need to check the low pressure side of the system and see what the operating conditions are,” he said. “The duct work has to be running at a temperature below the dew point temperature of the air in the restaurant. This is probably caused by dirty filters, a dirty coil, or a dirty fan. It is obvious that the ductwork surface area temperature is too cold for the conditions. I think there is a possibility that the exhaust fan is not removing the humidity from the air in the kitchen, causing it to drift into the dining room and raise the humidity. The first action that we will take is to tell the owner we’re going to repair the exhaust fan to get that humidity out of the building.”

They explained to the owner what they were going to do and went to the exhaust fan which was outside. Tim reached up and touched the motor. “Man this motor is red hot,” he said. “It must be sitting at locked rotor amperage and just building up heat.”

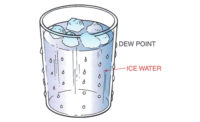

He reached over and turned off the disconnect to the motor. They removed the motor from the fan, and the shaft was locked tight on the motor. They went to a supply house, picked up a new motor, installed it, and turned the fan on. Then they got back to checking the suction pressure and discharge air temperature. The suction pressure showed that the evaporator was operating at 39° — well within range. When they checked the discharge air leaving the evaporator, they discovered that it was running at about 48°. The typical discharge air would be 55°. This meant that the ductwork had a surface temperature of close to 50° in the restaurant (Figure 1). This was a little low, so they went inside the restaurant and took some psychometric readings. They found that the dry bulb temperature was 75°, the relative humidity was 60 pecent, and the dew point temperature was 59° (Figure 2).

“The dew point temperature of the air in the conditioned space is our big concern,” said Bob. “It is 59°, which means that if the ductwork reads anything below that, moisture will begin to form. If it’s much lower than 59°, enough moisture will accumulate that it will start to drip from the ductwork.

“With the exhaust fan running, we need to watch the relative humidity and dew point temperature of the air in the restaurant to see if it starts down,” he continued. “The air leaving the coil is a little too cold — it should be about 55°. We may have an airflow problem, dirty filters, dirty coil, or dirty fan. Let’s examine the filters and fan and coil surface.”

Fortunately, they were working on a package unit on the roof where all of these components are accessible from the rooftop, and they didn’t have to go into the restaurant ceiling to perform this work. They shut the unit down and removed the panel to the fan compartment. They found that the coil was dirty and the fan wheel was dirty. They examined the filter, and it was fresh and clean. They then went down to the owner and explained that they were going to need to perform work on the coil and fan and asked him when would be a good time.

“We open at 7 a.m. and close at 10 p.m. every day of the week. So the work will have to be done after 10 p.m.,” he said.

Bob explained to him that work would have to be done on overtime, and he understood. That night they showed up at 9:30 p.m., shut the unit down, and removed the fan from the housing. They brought the pressure washer to the roof, so they could clean the coil. They applied the detergent to the coil to let it start soaking while they cleaned the fan. The fan had quite a bit of grease on it, and it took several applications of detergent and pressure washing to get the fan clean.

After the detergent had been soaking in the coil for about 45 minutes, they started pressure rinsing and cleaning from the coil discharge side, blowing back to the coil inlet side, backwashing the dirt from the coil.

“I have never seen so much grease and dirt come off of a fan and coil,” Tim said.

“Filters do not stop everything from going through to the coil,” Bob replied. “The smoke in the air is burned grease in suspension. The coil and fan are good surfaces for grease to drop out of the air and deposit on the fan blades and the coil surface. This coil has not been cleaned in many years.”

They got the coil and the fan clean, oiled the motor, and checked the belts. The belts were becoming worn, so they put new belts on the motor and fan. They had it all back together and were ready to start it up. They left the unit ready for the customer to start up first thing in the morning. Then they came to the restaurant around 1 p.m. to have lunch and observe the ductwork. The ductwork was not dripping anymore. Their remedy had worked perfectly. The exhaust fan helped keep kitchen exhaust and moisture from the main restaurant, and cleaning the fan and coil moved more air across the coil, so the dew point temperature in the restaurant showed that there was less moisture in the air after their fix. The owner was very happy and said they would be his service company from now on.

As they were leaving Tim said, “That was a very different job — I’m glad I had you with me because I don’t know if I ever would have figured that out.”

“Sure you would have,” said Bob. “You have to be able to figure these things out without my thinking. The first clue was the exhaust fan not working. The second clue was the discharge air temperature from the coil was a bit too cold. The third clue was the dew point temperature in the restaurant was high, meaning the humidity was high in the restaurant.”

“I like this about this field that we’re in,” said Tim. “It requires a good bit of thinking, but jobs that require thinking offer a better income.”

Publication date: 03/20/2017

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!