The Gold-winning Sporlan S3C series of case control products provide safety, security, and service for remote and self-contained refrigerated display appliances (single or multiple coil). The S3C family of controls includes a case controller, display module, and valve module that all support open protocol communication via BACnet and Modbus. The system is designed to facilitate both installation and integration by the refrigerated appliance OEMs as well as retrofit into existing supermarket refrigeration control installations.

Sporlan developed the series of tools using data gathered through surveys, interviews, and input from existing customers.

When enabled, the controller provides automated configuration and network integration. The S3C Case Control peer-to-peer system is capable of standalone or BAS coordinated control of up to eight refrigerated cases per lineup. This family of controls simplifies and shortens the time required to set up new equipment or retrofit an existing system for more precise control.

Jeremy Brown, foreman for DEEM Mechanical, a commercial and industrial mechanical and electrical company with offices in Lancaster, Missouri, said he found the controls save time for the technicians servicing them. The firm uses them at many of the Walmart stores it services.

“The case control does all the figuring,” Brown said. “Just as long as you have all your sensors in the right place, they are very user-friendly.”

The Sporlan Tech Check App provides a way to connect to the S3C controller to verify settings, change parameters, and troubleshoot the case. The S3C has the ability to connect to RS-485 and Ethernet at the same time.

The Sporlan Superheat Control Systems (SCS) are intended for use on refrigerated display cases, walk-in coolers, and other applications where easy setup and precise superheat control are desired. Control systems utilize either the Sporlan pulse width modulation expansion valve (SCS-PB) or a Sporlan step motor operated electric expansion valve (SCS-SB).

The systems are intended to reside in the refrigerated space and communicate via Bluetooth with the Sporlan Tech Check mobile app. Once the system is installed, configuration is accomplished via Bluetooth. A technician activates the controller’s hall effect switch to establish the Bluetooth connection and select the refrigerant, superheat, and pressure transducer range within the mobile app. On-board LEDs offer system status indication.

“Sporlan has found Bluetooth connectivity to be very successful,” said Heath Schaefer, Sporlan’s controls product manager. “The technician has the ability to connect, investigate, and troubleshoot the case without having the case opened up or dragging their tools into the store.”

If system data is needed, the controller collects data every 20 seconds and stores the last 30 days. That data can be transferred to the mobile device for viewing, graphing, and sharing with others.

Sporlan plans to continue the line by integrating the controls into other applications and cases.

The Cooling and Heating Division of Mitsubishi Electric Trane HVAC US took home the Silver award for its Building Connect+.

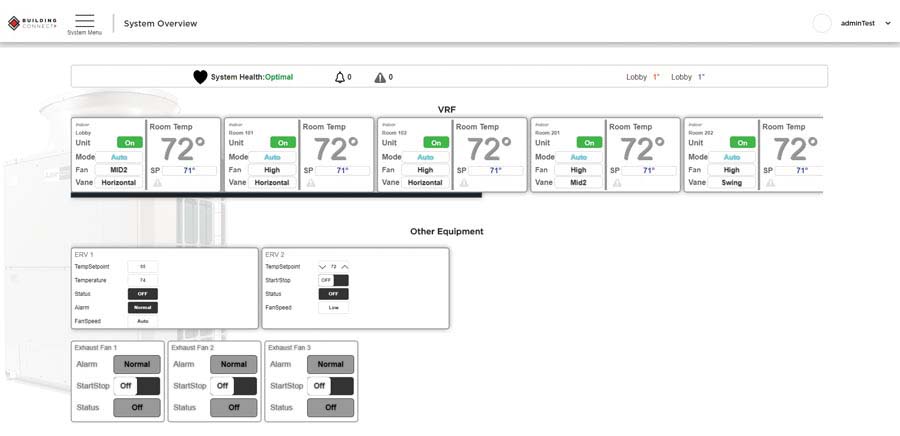

The systems provide a cloud-based controls platform for managing CITY MULTI® VRF systems, third-party BACnet® devices and hardwired equipment from one convenient interface. Using an on-site panel (BCP-50), the platform connects the central controller and third-party equipment to the internet. The panel can auto-discover and connect up to 50 CITY MULTI VRF indoor units, five BACnet devices, and eight hardwired devices using digital input/output, with configuration done through a simple web portal.

“This innovation is an ideal mid-level solution for facility managers who need more than a centralized controller but less than a full building automation system to run their facilities,” said Tom Greco, the company’s director of solutions business development.

Building Connect+ allows account managers to add and manage independent users, giving specific levels of access to approved users through internet-connected devices.

For inspections and service, Building Connect+ makes Maintenance Tool data available in the browser, enabling technicians to easily view performance data and error codes without additional hardware. The technician is empowered to choose which data is important for the user and set permission levels and appropriate alarms based on the use case onsite without any special programming knowledge needed.

The Bronze award went to the Color TEC3000 Series Smart Thermostat from Johnson Controls. A key improvement for this system is increased connections. Available in networked, wireless, or standalone models, this all-new controller is designed for multiple applications with both traditional and smart equipment. It works with building automation and control systems from Johnson Controls, including Verasys®, Metasys®, and Facility Explorer®, two- or four-pipe fan coils, and rooftop units with or without economizers and heat pumps.

The full-color, 4.2-inch LCD touchscreen delivers real-time status in easy-to-read plain text messages. An adjustable backlight brightens during user interaction. All models include a USB port to cut installation time through rapid configuration cloning. Field-selectable BACnet MS/TP or N2 networked communication makes it possible to upgrade from N2 to BACnet without changing hardware. It features automatic service reminders, alarm notifications, and programmable scheduling all in one design.

In researching contractor-oriented features to build into the design, operation, and function of the Color TEC3000 Series Smart Thermostat, Johnson Controls sought feedback on product specs from service technicians and systems specialists in branch offices around the world. The company reviewed customer requests and feedback with existing products. It then conducted surveys and focus groups with potential customers before implementation.

The ultimate goal is improving time efficiency for technicians.

“During the commissioning process, instead of having to go to every single room in a dorm, school, or large office building to test the heating, cooling, and fan on every single unit, now the technician can access the status for every single unit remotely,” said Gary Gavin, director of engineering for thermostats and sensors at Johnson Controls Inc.

Report Abusive Comment