Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were at a customer’s house doing a seasonal checkup on a condensing gas furnace. This was routine service carried out every year on this customer’s equipment per a service agreement.

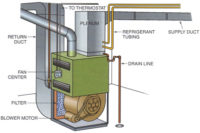

They changed the filter, oiled the indoor fan motor, and generally looked the furnace over for any problems, and everything looked good. The fan wheel was not dirty because the filters had been maintained through the years on this furnace. They went through the house and checked all of the air outlets to make sure they were all open like they should be. They had made sure that there was no blockage across the return air so they would get good airflow. They often found that if the return air grille is in the vicinity of furniture people will push the furniture up against the return air grille or sometimes put a block in front of it because it might create a draft to the furniture nearby. Everything on the house side of the system looked good so they decided to start the furnace.

They went to the thermostat and turned it to heat and turned it up about 3°F above the temperature setting of the house and they heard the furnace start, so they went to the basement to see how it was operating. When they got there, the furnace indoor fan was running. It operated off of a time delay rather than temperature. They looked in the sight glass to see what the burner looked like and it wasn’t burning. Tim asked, “What is going on here? If the indoor fan is running, it is bound to be calling for heat but the burner is not burning.”

Bob said, “I don’t know what’s going on. We need to check this out. It’s a good thing we didn’t just drive off and assume this furnace would start when there was a call for heat. We would have gotten a call back that very day. Our responsibility is to make sure the system is operable by making it operate before we leave.”

They removed the front door from the furnace and Tim noted that there was a trouble light blinking on the circuit board. They looked on the inside of the furnace and saw that blinking pattern indicated the furnace was not venting correctly. Bob looked at the vent motor and put his hand on it and said, “It seems to be running. I wonder if we have a control failure here.”

Tim then asked, “What is the control sequence with this furnace?”

Bob said, “The draft has to be proven before the flame will ignite on this furnace. Some of these furnaces have a little airflow switch in the piping that repositions when the airflow starts and closes a switch to allow the burner to come on. Some of the systems have a centrifugal switch in the back of the fan motor that proves that the fan motor is running before the switch will make and allow the burner to start. Let’s get the meter and determine what the method is on this furnace and see if that switch is closing when the fan motor is running. Turn off the furnace switch until we can get set up for this check.”

They found the method to check the switch and started the furnace and determined that the switch was not closing. Bob then said, “Either the switch is defective or there actually is no airflow for venting purposes. I think we should follow this PVC pipe vent to its termination point and see if we can detect any airflow at that point. That would be much easier than troubleshooting the fan motor.”

They went to the outside of the house where the PVC pipe came through the structure. It had a fitting on the outside that was both intake air and outflowing air from the vent (Figure 1). The outflowing air from the vent was just a plain piece of PVC pipe and when Tim looked in there, he said, “Here is our problem. There is an old bird’s nest in the end of it.”

Tim felt at the outlet and could feel no air flowing. He pulled the old bird’s nest out and commented that he could now feel the air flowing. He said, “I’ll bet that furnace is firing now.”

They went inside to the furnace and sure enough they could see and hear that the burner was operating.

Bob then said, “We have solved the problem today, but what is going to prevent it from happening again? That nest looks like the nest of a wren. It is a very small bird and can build in a very tight place. That pipe is about an inch and a half diameter inside which must be big enough for her to build a nest. Let’s drill a small hole on each side of that pipe and run a very small wire from one side to the other which will block the pipe and possibly discourage the bird from building again (Figure 2). The small wire will not be enough to impede the flow of the vent gases. Then each fall we should visually check that outlet to make sure that there is not a bird’s nest in it again, but I believe that this will cure it for a lifetime.”

Tim said, “Well I never thought we would have a service call like this. It seems like it’s something new all the time and the service technician must get creative almost every day. That is one of the things that makes this job so interesting. It constantly changes.”

Bob said, “You are right. I’ve been in this business for quite a while and constantly see new things happening. And about the time we understand this line of equipment, another line of equipment will be developed and we will need to learn again. This happens year after year after year for evermore. Keeping it constantly changing and constantly interesting. Let’s go and explain to the customer what we found and tell him to keep an eye on that vent in the springtime.”

Publication date: 9/19/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!