In December 2020, Congress passed the American Innovation and Manufacturing (AIM) Act, and in 2021, the EPA introduced a rule mandating an 85% nationwide phasedown in high-global warming potential (GWP) hydrofluorocarbon (HFC) refrigerants by 2036. This phasedown will be accomplished in three ways:

- Phasing down production and consumption;

- Maximizing reclamation and minimizing releases from equipment;

- Facilitating the transition to next-generation technologies and low-GWP refrigerants through sector-based restrictions. Many of these lower-GWP refrigerants are considered mildly flammable with an ASHRAE Standard 34 designation of A2L.

The transition to next-generation refrigerant technologies is being aided by the EPA’s Significant New Alternatives Policy (SNAP) program, which approves the use of low-GWP refrigerant for specific uses. Many A2L refrigerants have already been approved by the EPA with many more approvals in the works.

The goal of this paper is to provide information on refrigerant classifications, the differences between refrigerants, and the influences driving the shift away from traditional refrigerants to A2L refrigerants.

Refrigerant Classification

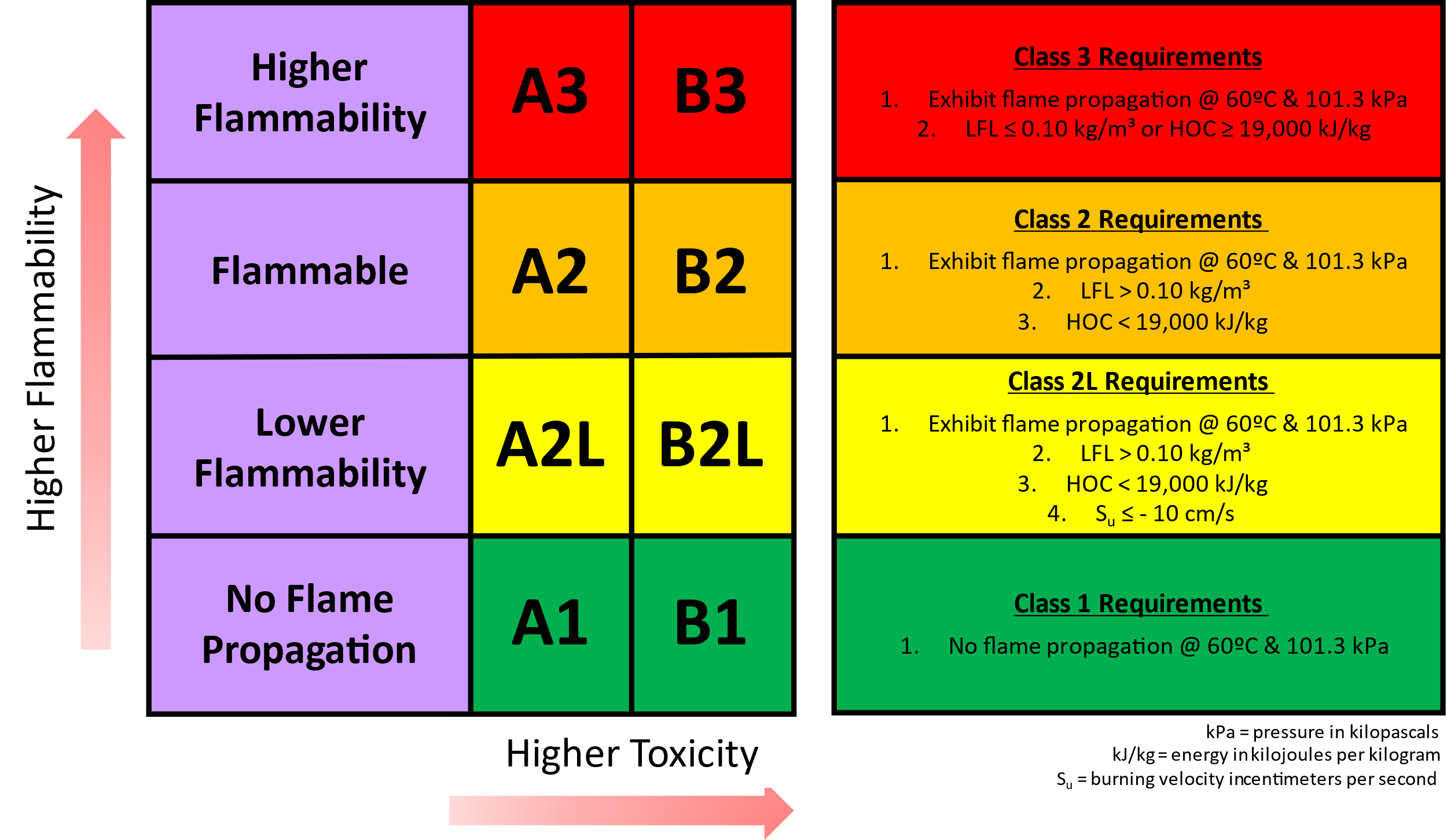

The ASHRAE Standard 34 classification table is designed to categorize refrigerants according to two primary factors: flammability and toxicity. Regarding flammability, refrigerants are tested and categorized by several factors, including how much refrigerant per unit volume of air will support combustion, the amount of energy needed to initiate combustion, the amount of energy released from combustion, and the rate of combustion propagation. Toxicity designated as A or B is defined by the occupational exposure limit (OEL). Lower toxicity refrigerants (A) have an OEL of ≥ 400 ppm, while higher toxicity refrigerants (B) have an OEL of <400 ppm).7

Click chart to enlarge

REFRIGERANT CLASSIFICATION: Toxicity designated as A or B is defined by the occupational exposure limit (OEL). Lower toxicity refrigerants (A) have an OEL of ≥ 400 ppm while higher toxicity refrigerants (B) have an OEL of <400 ppm. (courtesy of fieldpiece)< p> 400>

To give you an example of the classification table use, Table 1 describes various refrigerants and their classifications.

| Class A | Class B |

| A3 refrigerants such as R-290 Propane have a higher flammability and a lower toxicity. | At present there are no known B3 refrigerants. |

| A2 refrigerants such as R141B and R-406A are flammable and have a lower toxicity. | B2 classified refrigerants such as R-30 and R-40 are flammable and have a higher toxicity8. |

| A2L classified refrigerants such as R32, R-454B, and R-1234yf have a lower flammability than A2 and lower toxicity. | B2L classified refrigerants such as R-717 Ammonia8 have lower flammability and higher toxicity. |

| A1 classified refrigerants such as HFC R-407C and HFC R-410A have no flame propagation and low toxicity1. | B1 classified refrigerants such as R-10, R-21 and the rather obscure R-764 sulfur dioxide2 have no flame propagation but higher toxicity. |

Table 1

COMPARE AND CONTRAST: Refrigerants compared by class and flammability. (Courtesy of Fieldpiece)

Flammability

Since A2L refrigerants are mildly flammable, it is important to understand the characteristics of flammability and how they are affected by the HVAC environment. There are three important factors when understanding flammability:

- Lower Flammability Limit (LFL): The concentration in air necessary to generate a flammable mixture.

- inimum ignition energy (MIE): The lowest energy required to ignite the flammable material in air or oxygen found at a certain optimum (stoichiometric) mixture.

- Heat of combustion (HOC): The amount of energy that is obtained from the burning of a volume of gas is measured in Btu.

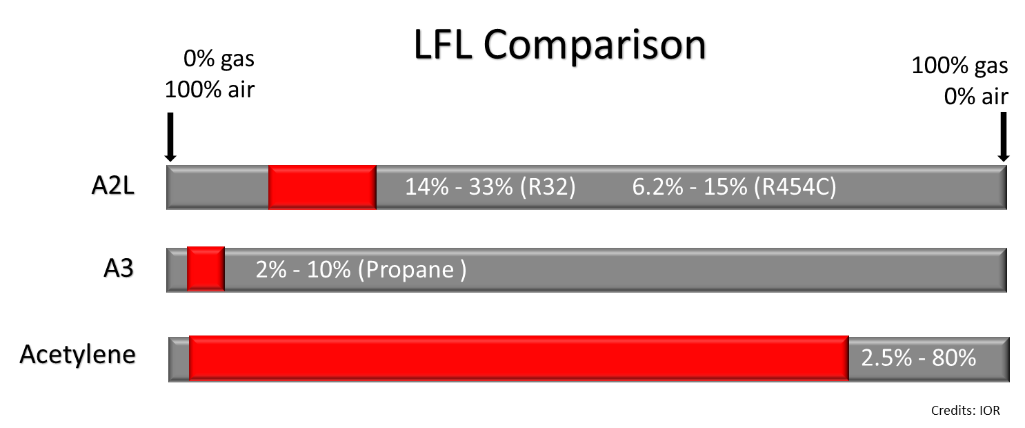

LFL - Lower Flammability Limit

Mildly flammable A2Ls consist of HFCs, hydrofluoroolefins (HFOs), and also blends of these two synthetic refrigerants that have a high LFL, often eight times higher than A3 refrigerants, such as R-290 propane. This means a much larger concentration of A2L must be present to form flammable concentrations. This is important when considering refrigerant leakage, especially in enclosed spaces. While a very low amount of A2 or A3 refrigerant in an enclosed space can be very dangerous, A2L refrigerants require a much larger amount of gas leakage to reach sufficient concentrations necessary for ignition.

Click chart to enlarge

GAS AND AIR: LFL comparison based on percentage of gas and air. (Courtesy of Fieldpiece)

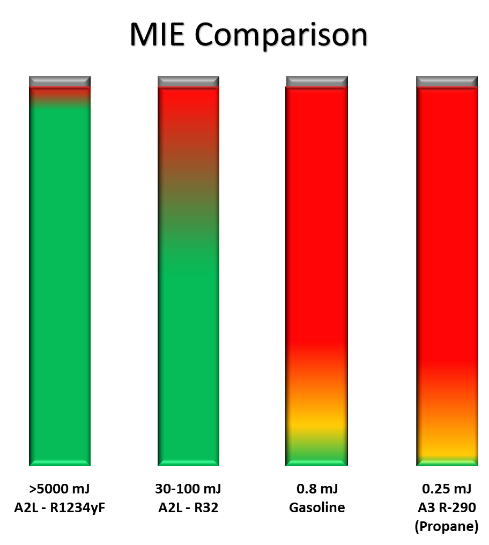

MIE - Minimum Ignition Energy

A2L refrigerants have a significantly higher minimum ignition energy (MIE), which means it is harder to ignite than A3 refrigerants. Hydrocarbon vapors, such as propane (R-290), can be easily ignited by many energy sources, even sometimes by the lower levels produced by static electricity.5 This can be orders of magnitude lower than the levels required to ignite the A2L refrigerants. Even gasoline has a much lower MIE than A2L refrigerants by almost a factor of 10!6

Click chart to enlarge

MINIMUM IGNITION ENERGY: A2L refrigerants have a significantly higher minimum ignition energy (MIE) which means it is harder to ignite than A3 refrigerants. (Courtesy of Fieldpiece)

HOC - Heat of Combustion

Heat of combustion is the amount of energy released during combustion. The units of measure for HOC are expressed either in kilojoules per gram (kJ/g) or Btu/lb. Simply stated, you can think of HOC as the violence of the reaction when a gas ignites. A3 refrigerants, like propane, have a very high HOC on the order of 19,905 Btu/lb. whereas A2 and A2L have much lower values on the order of 2,700-4,400 Btu/lb. This means that while A2 and A2L refrigerants can, under the right circumstances, burn with veracity, they are generally not in the category of explosion hazard like you would find in A3 refrigerants.

What you may find interesting is that the HOC for an A1 refrigerant like R-410A is 2,800 Btu/lb., and a nominal A2L refrigerant, such as R-32, has an HOC of 3,869 Btu/lb. Given a typical residential ducted split unit charge being ~ 15 lbs., there is essentially only about 24,000 Btu difference between the A2L and R-410A. This difference is equivalent in relative comparison to burning 3.4 lbs. of dry wood (about 2.5 feet of dry 2x4) versus burning 1.7 lbs. Duraflame™ wax fire log (about 38% of a single log.)3,9

Flammability Summary

You can summarize refrigerant flammability into the ease of ignition, expansion, or propagation of the flame and the amount of energy release.9

- Class 1 refrigerants have no propagation at 60ºC but may still be flammable at higher temperatures.

- Class 2L refrigerants are “mildly flammable,” difficult to ignite with a relatively low energy release, and low flame propagation speed.

- Class 2 refrigerants ignite easily with a relatively high energy release.

- Class 3 refrigerants ignite very easily and are potentially explosive.

Compared to A1 refrigerants, A2Ls have slightly higher flammability properties, and if burned, produce similar types and amounts of by-products (e.g. HF) and somewhat higher heat of combustion/fuel value. Flammability risks from A2L refrigerants will be mitigated by a variety of equipment design changes, applicable codes and standards, and technician training. The lower flammability limit of A2L refrigerants is very high, which means a high concentration of refrigerant is needed to create a flammable mixture (ASHRAE 34).9, 10

So How Does This Affect Me?

The move to A2L refrigerants is happening now and is likely to accelerate. Even though the EPA has issued their rules to move away from high-GWP refrigerants to low-GWP refrigerants as found in A2Ls, state and local legislation will still need to allow the use of these more flammable refrigerants. There are currently 25 states that allow the use of A2Ls either for air conditioning only or air conditioning and refrigeration. Many more states have legislation under review.

Since each state handles the code-making process differently, it is important to understand your local building codes for A2L allowance. Except for a few, like Illinois and Texas, most states have a statewide code process. For states without codes, legislation needs to pass guaranteeing the acceptance of A2L refrigerants approved by U.S. EPA SNAP throughout the state. Please refer to your state and local building codes for specific information on your situation.

The shift to more flammable refrigerants will require the appropriate equipment for installation and servicing. It is critical to make sure your test equipment is compatible with A2L refrigerants. At Fieldpiece, we have the products you will need to safely navigate this transition. The following Fieldpiece test tools have been deemed compatible for use with A2L refrigerants:

| Product # | Description | Product # | Description |

| MR45 | Recovery Machine | DR58, DR82 | Leak Detectors |

| SM380V, SM480V | Refrigerant Manifolds | MG44 | Vacuum Gauge |

| JL3KH6, JL3KR4, JL3PC, JL3PR, JL3RH | Charge and Air Kit Probes | SR47 | Refrigerant Scale |

| VPX7, VP87, VP67 | Vacuum Pumps |

Table 2

A2L COMPATABILITY: A list of Fieldpiece equipment that’s compatible with A2L refrigerants. (Courtesy of Fieldpiece)

Citations

- An introduction to A2L refrigerants and their use in Refrigeration, Air Conditioning and Heat Pump applications, FETA 2017

- Refrigerants Codes & Standards in Canada 2018

- A2L Terms You Should Know

- A2L and A3: the better you know them, the better you use them.

- What Are A2L Refrigerants and Why Do We Need Them?, C-11869 (7/22), Chemours

- MIE Minimum Ignition Energy, Thorne & Derrick International

- ANSI/ASHRAE Standard 34-2010, Designation and Safety Classification of Refrigerants. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2010-07-01. ISSN 1041-2336

- ANSI/ASHRAE Standard 34-2007, Designation and Safety Classification of Refrigerants. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2008-06-26. ISSN 1041-2336

- AHRI Chapter 2. Chemical, Physical, and Environmental Properties of ASHRAE Standard 34 and ISO 817, chapter 2, pg 3

- http://lifefront.eu/refrigerant-leakage-database/

Report Abusive Comment