The Internet of Things (IoT) is a harvester of connectivity, offering numerous benefits to the built environment and the HVAC equipment designed to keep its occupants comfortable. The IoT is defined by many roles, including data collection, remote accessibility, systems monitoring, air quality sensors, occupancy detection, and much more.

The ACHR NEWS compiled a list of the top 5 benefits IoT technologies can offer contractors based on information provided from a handful of HVACR controls manufacturers.

1. Healthy Indoor Spaces

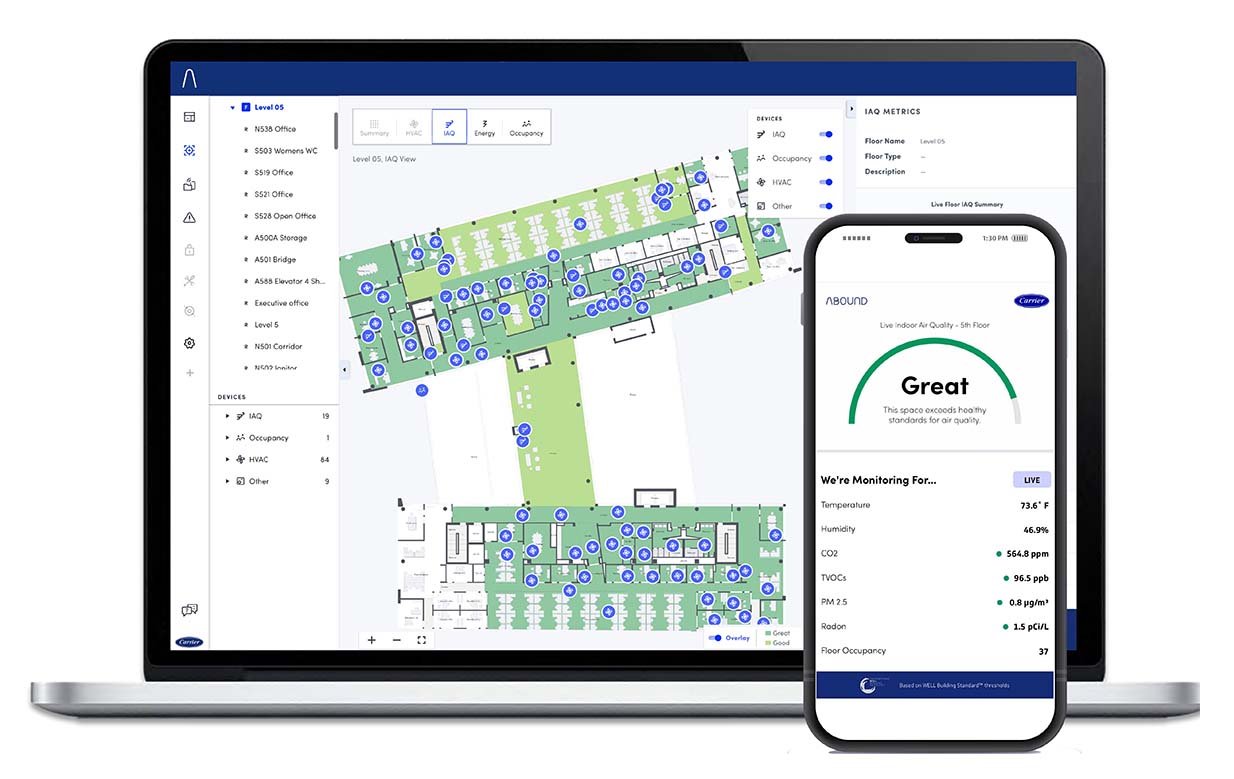

According to Forbes, health and safety are still concerns for 66% of employees returning to the office. IoT devices can help optimize ventilation systems, which has been proven to improve the cognitive function and health of occupants.

“Today’s workforce likes to know if the buildings they enter, work, or live in are safe and good for their wellness,” said Yasir Qureshi, general manager of Abound and digital products, Carrier. “On-demand assets and services can enhance the occupant experience. Monitoring and providing IAQ transparency creates a better understanding of the work environment, and using the IoT allows property owners and developers to reduce tenant concerns.”

To reliably track and continuously optimize IAQ, many building owners opt for IoT-driven systems that allow contractors to review data and provide insights on how to improve performance and provide a healthier indoor environment.

“Even well-managed buildings can experience periods of poor IAQ; and smart, IoT-connected systems dynamically adapt to changing conditions in buildings to maintain healthy air quality,” said Vineet Sinha, vice president, OpenBlue enterprise solutions, Johnson Controls. “When it comes to using IoT for occupant comfort and productivity, packaging demand control ventilation with IAQ improvements delivers a roadmap for healthy spaces and sustainability, enabling contractors to lower energy usage by 10%-15%.”

manager, smart building programs

Siemens Smart Infrastructure USA

2. Connectivity

Remote equipment access, connectivity, and centralized resources can offer contractors immediate paybacks.

Connectivity may mean remote access to a facility — perhaps a phone app to check an alarm or troubleshoot a hot/cold call — or harvesting data off-site that can be used to help identify opportunities for improvement.

(Courtesy of Carrier, click to enlarge.)

“No one, including contractors, benefits from excess windshield time,” said Brian Meyers, system controls portfolio leader – system controls, Trane. “Scheduled maintenance intervals can be difficult to get just right; visiting too frequently is wasteful and time-consuming and visiting too infrequently may cause equipment problems and inefficiencies. IoT connectivity can turn some maintenance into more efficient, on-demand maintenance through usage-based, predictive maintenance. This transition can improve outcomes with less effort. Set points for an entire facility can be sampled without ever leaving the comfort of an office.”

One of the most impactful developments in the IoT space may be the broader acceptance of secure, remote connectivity as a digital enabler both during and after construction.

“Remote, secure connectivity allows controls providers to perform aspects of their work remotely in the form of electronic pre-fabrication and then provide enhanced digital commissioning to streamline operational validation,” said Chris Pelton, P.E., manager, smart building programs, Siemens Smart Infrastructure USA. “Establishing a remote connection early in construction often requires close coordination with the owner’s IT department to select an approved cyber-secure method for network access, so it makes sense to work with someone who can bring cybersecurity expertise to the discussion.”

3. Customer Satisfaction

Connected, IoT technologies truly take off when contractors use them as tools to generate desired customer outcomes.

“Speed to resolution, closing labor shortage gaps, and generating sustainability progress are all of critical interest for customers in our industry,” said Tyler Haak, vice president of sustainability and service at Schneider Electric. “It’s not the technologies themselves that solve these problems, but the way contractors are able to deploy their services around the insights they generate. Improving the occupant productivity and user experience is one benefit that has tangible data available around the business impact of employee retention, tenant satisfaction, and absenteeism.”

When it comes to deploying IoT solutions, contractors should pay close attention to their customers’ needs and desires and act accordingly.

“Customers get excited when partners help them address their business challenges,” said Meyers. “They are looking to achieving sustainability goals, attract and retain employees, and improve system reliability, among others. Once a contractor understands the most important challenges for each individual customer, connected controls can often provide significant return on investment [ROI].”

4. Business Growth

From an ROI standpoint, adding IoT solutions to a contractor’s portfolio of offerings provides an opportunity for business growth.

“Calculating the ROI of IoT technology investment from an end-user standpoint can be complex as, oftentimes, these solutions can deliver multiple use cases that benefit other stakeholders in addition to the facilities manager and staff,” said Pelton. “Encourage clients to involve these stakeholders early to understand the business impact, evaluate costs/benefits more broadly, and ensure IoT solutions garner financial support.”

Productivity has become a primary motivator for many owners and their servicing contractors because it can free up valuable, often scarce, resources, allowing them to work on more valuable tasks.

“It all starts with base information, which provides data about HVAC equipment from its health history with specific recommendations to repairs performed and parts used,” said Qureshi. “When this data is combined with work orders and different events, like customer calls, waiting times for parts, plans for field visits, and validation of work, it creates a timeline of equipment health and all the activities around the equipment’s life cycle. This leads to the ability for contractors to provide predictive maintenance rather than preventative maintenance, saving them time and money.”

5. Sustainability

IoT applications can help building owners achieve sustainability objectives and environmental, social, and governance (ESG) goals through improved visibility, tracking, managing and reporting of metrics like energy efficiency and carbon emissions.

“Globally, there are increasing state and federal laws and mandates for greenhouse gas emissions, and many companies see ESG as a value driver for their customers and sustainable investors,” said Qureshi.

The pressure to decarbonize is coming from several quarters, such as the U.S. Securities and Exchange Commission’s (SEC’s) new rules for ESG reporting and climate disclosures. However, many organizations are having trouble measuring and meeting their decarbonization commitments.

“The IoT can help solve these issues in by the form of enabling low-cost, digitally automated data collection and analytics tools,” said Sinha. “Users can leverage these tools to digitally assess energy consumption, carbon footprints, set emissions targets, manage emissions, and track progress for reporting and apply AI-powered optimizations to meet their goals. This is much more efficient and accurate than manual reporting operations.”

Where to Start

For many contractors, the thought of implementing IoT technologies into their companies can be overwhelming. Numerous HVACR manufacturers insist it doesn’t have to be.

“When a contractor is just getting started, they should incorporate smart building technologies within their own facilities and learn about the benefits they bring or the gaps they fill,” said Haak. “Test to see what fits and improve your acumen. Once comfortable, go speak with customers to understand what issues they might be looking to resolve before determining which connected technologies to deploy. Let real guidance from folks who rely on you the most guide your first steps in deployment.”

Pelton said it’s crucially important for contractors to gain a better understanding of the IoT before trying to sell it.

“Learn how these IoT systems can impact a facility’s BAS architecture and IT dependencies,” he said. “This will help contractors better understand the skills that may be required before they aim to build them into their talent acquisition plans. Contractors can either build up this competency in-house over time or choose industry partners who can serve as an extension to their company’s value delivery.”

Becoming a technological wizard is not going to happen overnight. Rome wasn’t built in a day, and digital infrastructure is no different.

“Specialization with IoT products requires training,” said Qureshi. “Take the time to build a skill set and proactively network with other contractors. Find out what works for them and their IoT use cases and proceed from there.”

Even though adding new technologies may be fun and exciting, Meyers offers one final piece of advice: “Don’t chase technologies, chase outcomes.”

Report Abusive Comment