In the summer, the DOAS dehumidifies the outdoor air before it enters the space. The outdoor air unit is sized to deliver the required amount of outdoor air conditioned to handle the latent load of both the outdoor air and the space. This requires a supply air dewpoint lower than the room air dewpoint, typically 48-50 DPT. Because the outdoor air unit is handling the entire latent load, the space sensible load is decoupled from the latent load, allowing precise humidity control regardless of the space thermal load. This minimizes the humidity control problems often associated with part-load operating conditions. The local HVAC units (parallel VAV systems, water source heat pumps, fan coil units, and induction units) are only responsible for the sensible cooling needed for each space.

OPTIMIZING THE DOAS SYSTEM

There are several considerations to make in order to maximize the savings from a DOAS. Items to evaluate include the use of energy recovery, supply air temperature, supply air delivery location, and the system’s sequence of operation.ENERGY RECOVERY

Since dedicated outdoor air systems are by definition 100 percent outdoor air (OA) systems, energy recovery is required in most cases per ASHRAE 90.1-2004. Section G3.1.2.10: Exhaust Air Energy Recovery. The standard requires the following: “Individual fan systems that have both a design supply air capacity of 5,000 cfm or greater and have a minimum outside air supply of 70 percent or greater of the design supply air quantity shall have an energy recovery system with at least 50 percent recovery effectiveness. Fifty percent energy recovery effectiveness shall mean a change in the enthalpy of the outdoor air supply equal to 50 percent of the difference between the outdoor air and return air at design conditions.”

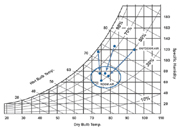

Figure 1. (Click on the image for an enlarged view.)

Energy wheels also ease the burden of dealing with part load conditions. Because the wheel transfers both sensible and latent energy, the energy wheel “compresses” the conditions entering the downstream cooling coil. Instead of having to design a control strategy for that coil to handle all ambient air conditions, the conditions entering the cooling coil are held to a small radius around the room conditions. (See Figure 1.) This is particularly important for DX equipment, where excessive compressor cycling at low load conditions leads to loss of humidity control.

Depending on the climate and the end user preference, plate type heat exchangers can also be implemented into a DOAS. Plate exchangers offer energy recovery through sensible preconditioning of the outdoor air.

OUTDOOR AIR (SUPPLY AIR) TEMPERATURE

The supply air temperature of the DOAS is an important factor in achieving maximum energy savings. As discussed previously, in order to handle the entire latent load, the supply air must be dehumidified to a dewpoint that is lower than the space, which typically means over-cooling the outdoor air. Designers must choose whether to supply air at “space neutral” conditions or at “cold air” conditions (the conditions off the cooling coil). When “space neutral” air is supplied, the dehumidified air is reheated to room conditions to introduce fresh air into the space without affecting the thermal loads. In this case, all of the sensible cooling that was done during dehumidification is wasted. When “cold air” is supplied, the air coming from the unit is not reheated, but instead left at the temperature coming off of the cooling coil. In this case, the outdoor air can handle some of the sensible cooling in the space. By decreasing the sensible loads in the space, the cooling capacity and annual energy consumption of the local HVAC unit are significantly reduced. Analyzing the loads of a typical wing of classrooms in a school, supplying “cold air” to the space reduces the local HVAC unit size by up to 40 percent when compared to supplying “space neutral” air to the space.OUTDOOR AIR DELIVERY LOCATION

Where the outdoor air is delivered impacts the energy efficiency of the system. Designers must choose whether to deliver the outdoor air directly into each space, or into the local HVAC unit.DELIVERING AIR DIRECTLY INTO THE SPACE

This is the most economical option, and the easiest to verify that the required volume of outdoor air is being supplied. Supplying the outdoor air directly into the space also has the greatest effect on the thermal loads. Because the local HVAC unit only needs to be energized on a call for cool or heat from the space, it will not need to be running when there is no call for tempering. This can greatly reduce the fan energy consumption of the local HVAC unit. In addition, the local unit will only need to be sized for the air volume required to satisfy the space sensible load rather than the entire supply air volume, saving on first cost, physical size, and potentially reducing sound levels.DELIVERING AIR INTO LOCAL HVAC UNIT

If it is not possible to deliver the air into the space directly, ducting the outdoor air directly to the local HVAC unit is an option. The cooling capacity of the local HVAC unit can still be decreased, but it will need to be sized to handle the entire supply air volume. If the design requires that the outdoor air be supplied to the local HVAC unit, it is highly recommended that the DOAS unit not reheat the outdoor air to avoid the local unit having to recool the air that has already been cooled once.CONTROL STRATEGIES

Controlling a DOAS is straightforward: when the building is occupied, the DOAS unit is energized and supplying conditioned outdoor air to the space. The local HVAC units are energized upon a call for cool or heat from the space. This system allows the precise volume of outdoor air to be delivered to the space independent of cooling or heating status of each space. In addition, there are several measures that can be implemented to further enhance system performance.Resetting the discharge temperature based on outdoor air is one control strategy that can be implemented. When outdoor air conditions are such that overcooling is likely, the supply air is reheated to a neutral temperature. This can be accomplished using a microprocessor controller (DDC) for discharge air control; the DDC controller monitors the ambient temperature and resets the discharge temperature of the outdoor air unit accordingly. A more advanced approach to this same strategy is to implement a BMS that can monitor multiple spaces and determine the “critical space.” Once the critical space is determined, the BMS can adjust the reheat capacity of the outdoor air unit to prevent the critical space from being overcooled or overheated.

Another controls strategy for saving energy is implementing a dehumidistat in the space to monitor room humidity. If the room becomes too humid, the dehumidistat sends a signal to the microprocessor controller that more dehumidification is needed. The controller then lowers the discharge dewpoint of the outdoor air unit for further dehumidification. Once the room humidity reaches an acceptable level, the dewpoint is reset back to normal operation.

SUMMARY

Dedicated outdoor air systems provide a straightforward, energy efficient approach to handling ventilation air. Considering the use of energy recovery, supply air conditions, delivery location, and the correct sequence of operation will maximize the annual energy savings dollars for the owner and the comfort level for the occupants.Reprinted with permission from the Greenheck Fan Corp. Website. For more information, visit www.greenheck.com.

Publication date:05/04/2009

Report Abusive Comment