You can compare the operating pressures of the system to its charging charts (when you can find them), but the machine has to have fairly serious problems for this method to be helpful. There is a definitive way to determine the performance of a heat pump in heating which involves measuring its total airflow, which allows you to calculate the actual heat output of the system and then compare it to its published performance data.

While this is the most accurate way to evaluate a heat pump’s performance, it really is impractical for the average situation. Usually this procedure is reserved for those situations that justify the extra time and expense.

So the question is, how can we do our best to evaluate a machine in heating with the circumstances presented to us?

USING FEEDBACK: TEMP SPLIT

Well, we have to use all of the feedback the system is giving us, including the values mentioned above, but we have to keep in mind the limitations of this feedback.One of the indicators of performance for the system in heating is the temperature differential between the return air and the supply air, also known as temperature split or delta T. I recommend you use temp split as a performance indicator.

It makes me uncomfortable discussing this topic with you; each year I spend the whole cooling season discouraging people from using temperature split as a cooling performance indicator. In cooling mode, the temperature split is a terrible performance indicator. But in heating, it is somewhat less terrible.

The reason temperature split is a poor performance indicator is because there are so many variables besides system capacity that affect it, such as airflow, coil cleanliness, indoor humidity, and system design variables. But in the heating mode, there is one less variable to contend with: indoor humidity (the machine is not making condensate). So in heating, although the other information we are getting from the system is so vague, temperature split is a slightly more valuable tool.

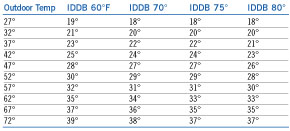

To help you get a general idea of what the temperature split could look like on a system in heating, I’ve generated a chart from some performance data of a 3-ton package heat pump (Table 1). This chart can give you a general idea what a pump’s split should be, but it’s important to remember that all pumps have their own unique performance curve, so use this information judiciously.

The chart is based on a system total airflow of 400 cfm per ton, so if the system you’re evaluating has low airflow, its split will be abnormally high; if its airflow is above normal, its split will be abnormally low.

Of course, when using temperature split, you must take into consideration that if the indoor coil is dirty, the split will be higher than normal. If the outdoor coil is dirty, the split will be lower than normal.

TIPS FOR THE BEST EVALUATION

Here are some tips for maximizing your effectiveness while evaluating heat pumps in the heating season.Because of the low rate of refrigerant flow in heating, it takes a long time for a heat pump’s refrigerant system to reach equilibrium after starting. Equilibrium means that all of the refrigerant has returned to the place it’s supposed to be during operation. Because of this, you will need to allow the system to operate longer before taking the performance measurements seriously.

I can’t give you a certain time interval because it changes with the load conditions under which the system is operating. The colder the weather, the longer it takes. One way to tell if a system has reached equilibrium is to monitor its pressures and temp split from the beginning of the cycle and wait to begin your evaluation until these indicators have stabilized.

During the heating season, the only way to ensure that a pump has the correct refrigerant charge is to weigh it in. Attempting to charge or adjust the charge by any other method is futile. You can prove this to yourself by trimming the charge of a package system that appears to be low; when you have finished, remove the charge, weigh it, and compare its weight to the factory charge listed on the name plate. This can be a humbling experience.

Always measure the temperature split temps just entering and leaving the machine, as well as at the registers. The temperature split at the machine tells you how the pump is performing. Taking the temp split at the registers includes the ductwork heat loss in the reading, which can distort your interpretation of how the heat pump is operating.

The extra bonus for taking the split at the registers and the machine is that comparing the two sets of readings can quickly reveal ductwork heat gain or heat loss problems.

It’s not easy to determine if a heat pump is operating properly in heating; it’s almost an art form.

Publication date: 01/14/2002

Report Abusive Comment