Putney Central School has three wings heated by three hot water boilers. Dataloggers were deployed on each boiler’s oil burner to determine daily operating time.

PUTNEY, Vt. - Putney Central School, K-8 grades, has three wings, which were constructed in 1955-64, 1974, and 1996. They are heated by three hot water boilers. Each wing is a separate heating zone identified as zones A, B, and C.

Dataloggers were deployed on each boiler’s oil burner to determine daily operating time. Fuel splits were calculated by multiplying the burner operating time by the burner nozzle throughput and the heating value of fuel oil. This fuel split was then converted to Btu per square foot-year to determine the relative heating efficiency and fuel consumption in each of the three zones.

The fuel split was further converted to Btu per square foot-year-heating degree day. This calculation showed the relative efficiency of heating adjusted for heating degree day. If the number found by this calculation is less than five, then the building heating efficiency and envelope thermal efficiency are good. If the number is greater than five, there is room for improvement. Further investigation, however, is needed to determine the contributing factors to higher numbers.

An energy audit was performed on the Putney Central School in 2008. The building energy performance was computer-modeled using Trane Trace 700 software. The zone energy splits between the computer model and those determined by dataloggers were compared. The computer model used with the associated assumptions was found to inaccurately predict building performance. The computer model varied from the datalogger energy use by 7-42 percent.

DATALOGGER DEPLOYMENT

Motor run time dataloggers were deployed on boilers serving heating zones A, B, and C at Putney Central School on April 1. Dataloggers were removed on May 7.Boiler A serves the gym and a front wing built in 1957 and 1964. Boiler B serves a middle school built in 1974. Boiler C serves a wing built in 1994. Boiler A has a 1-minute purge cycle at the end of firing, which was subtracted from each burner cycle time.

Analysis of the data was done for the coldest day during the period, April 13. The day had a high temperature of 39.3°F and a low temperature of 31°.

The use of oil for April 13 is given in Table 1; extrapolated over the year with annual oil consumption of 14,500 gallons, the fuel oil split and heat loading by school zone is given in Table 2.

Table 1. Fuel splits between heating zones, April 13, 2009.

DATA INTERPRETATION

Boiler B in the middle school had the highest heat load per square foot of floor area at 16.7 Btu per square foot-year-heating degree day. The area served has a high outside wall area for the floor space and contains an entry corridor with a large glass area. The boiler and overall heating efficiency appear low.Boiler A serving the gym and front wing had the next-highest heat load per square foot of floor area at 6.9 Btu per square foot-year-heating degree day. The boiler was oversized for the heat load and replacement should be considered. Insulation, ventilation, and air-handling unit upgrades should be accomplished before the boiler is replaced.

Boiler C serving the new wing had a heat load at 3.6 Btu per square foot-year-heating degree day, which reflects better insulation, thermal pane windows, and a heat recovery ventilation system. This boiler appears to be oversized. Consideration should be given to using Boiler C to provide the heat for the Boiler B area and removing Boiler B. Verification of Boiler C run times during the coldest part of the year should be done before heating system modification.

Table 2. Heat loading by school zone. (Note: Square feet is the area of the heated space served by the boiler; sf is square foot; yr is year; HDD is yearly heating degree days. For Putney HDD is based upon 7,200 annual heating degree days. Btu/sq ft/yr/HDD less than 5 indicates an efficient heating system. Btu/sq ft/yr/HDD greater than 5 indicates improvements can be made to the heating and building envelope system.)

COMPARISON TO MODEL

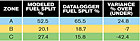

The school was modeled using Trane Trace 700 software. A comparison of actual building performance with the model is given in Table 3 with annual fuel splits in percentage. Variance compares the datalogger actual performance with the modeled performance.As can be seen from Table 3, the modeled building performance by zone varies from actual performance by 7-42 percent. Thus the model as used in this example is an inaccurate tool in predicting building performance. Energy conservation measures based upon the model would not reflect current and future building performance.

Dataloggers were deployed to determine the fuel splits for three heating zones in a local school. Results were converted to a measure of building heating efficiency of Btu per square foot-year-heating degree day. The zones varied from 3.6-16.7 Btu per square foot-year- heating degree day.

Table 3. Comparison of modeled school performance to actual performance.

The actual building heating performance found through dataloggers was compared to computer- modeled building heating performance. The computer model was found to be off by 7-42 percent compared to actual performance.

Dataloggers provide a simple and accurate method to determine actual building performance. They can be used to obtain building performance baseline data. From this baseline data, energy conservation measures (ECMs) can be proposed with real building information. Reductions in energy use from installation of ECMs can then be measured and verified through subsequent datalogger deployment.

Publication date:01/25/2010

Report Abusive Comment