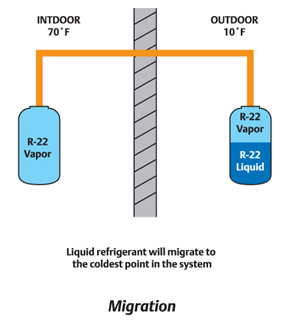

Migration

What is migration?Migration is the term used to describe when refrigerant moves some place in the system where it is not supposed to be, such as when liquid "migrates" to the compressor sump. This phenomenon occurs because refrigerant will always migrate to the coldest part of a system.

As an example, in a split air conditioning system with the compressor/condenser outside, liquid refrigerant from the evaporator will migrate to the compressor during winter months due to the compressor being colder than the indoor (evaporator) temperature. If this is not prevented, then upon startup in the spring, compressor slugging and damage may occur.

How can I prevent migration?

There are two common methods used to prevent migration:

1. Use of a pump down system.

2. Use of a crankcase heater to "drive off" any liquid refrigerant.

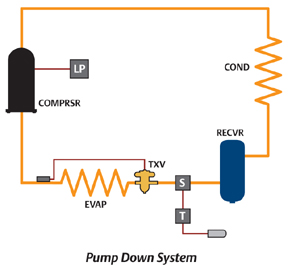

Pump Down Systems

What is a pump down system and when should it be used?A pump-down system consists of a normally closed solenoid valve installed in the liquid line and a low-pressure control that senses suction pressure.

The system operation is as follows: A thermostat is wired to the liquid line solenoid valve. On a call for cooling, the thermostat contacts close. This causes the solenoid coil to be energized, opening the valve. Liquid refrigerant flows into the evaporator and the suction pressure rises above the low-pressure control setpoint. The contacts on the low-pressure control close and the compressor begins to run.

When the thermostat is satisfied, its contacts open, causing the solenoid valve to close. This stops refrigerant flow into the evaporator. As the compressor continues to run, refrigerant is pumped out of the evaporator coil and suction pressure falls. When the suction pressure reaches the cut-out setting on the low-pressure control, its contacts open, stopping the compressor. This removes all refrigerant from the low side of the system during the off-cycle.

What is the advantage of a pump down system?

The advantage of a pump down system is that all of the liquid refrigerant is stored in the receiver and condenser when the compressor is not operating. This prevents liquid migrating to the compressor crankcase during the off-cycle and the ensuing possibility of liquid slugging at compressor startup.

Quick Facts is courtesy of the Flow Controls Division of Emerson Climate Technologies (formerly Alco Controls). For more information, visit www.emersonclimatecontractor.com.

Publication date: 10/03/2005

Report Abusive Comment