Types Of Refrigerants

In the air conditioning and refrigeration industry, virtually all of the refrigerant experience has been limited to single-component ("pure") refrigerants; however, as we search for acceptable replacements for these compounds, refrigerant manufacturers have been unsuccessful in developing single-component replacements that meet all of the required or highly desirable characteristics for a widely used refrigerant.

These requirements include:

Many of the R-22 refrigerant replacements under consideration are not pure, but instead are azeotropes, zeotropes, or near-azeotropes, or of two or more compounds. Fortunately, the commercial refrigeration industry has already had considerable experience with each type.

A mixture's components are chosen based on the final characteristics desired. These characteristics could include vapor pressure, transport properties, lubricant and material compatibility, thermodynamic performance, cost, flammability, toxicity, stability, and environmental properties. The proportions of the components are chosen based on the exact characteristics desired in the final product.

Behavior Of Mixtures

When an azeotrope, near-azeotrope, or zeotrope is in the pure liquid or pure vapor state, the composition is totally mixed, and all properties are uniform throughout; however, when both liquid and vapor are present (such as in the evaporator, condenser, or perhaps receiver), a mixture's behavior depends upon whether it is an azeotrope or zeotrope.

The percentage composition of the liquid and vapor of an azeotrope will always be virtually the same when both liquid and vapor are present. If a leak occurs, there will not be a substantial change in composition of the refrigerant left in the system.

The composition of the vapor and liquid of a zeotrope are different when both liquid and vapor are present. If a leak occurs in this region of a system and only vapor leaks out, there can be a change in the composition of the refrigerant left in the system. Also, if the system uses a flooded evaporator or multiple evaporators, the composition of the liquid can be substantially different from the vapor, resulting in changes in the circulating refrigerant.

Since a near-azeotrope is still a zeotrope, the composition of the vapor and liquid will be different when both liquid and vapor are present, but to a small extent. If a leak occurs in this region and only vapor leaks out, there can be a small change in the composition of the refrigerant left in the system.

Since the composition of the liquid and vapor of a zeotrope (and near-azeotrope) can be different, it is important to charge a system with these types of refrigerants with liquid leaving the cylinder. If vapor is charged from the cylinder, the composition of the refrigerant in the system may not be the same as that in the cylinder because of the fractionation of the refrigerant in the cylinder as vapor alone is removed. Refer to refrigerant manufacturers' guidelines for further details.

Additional information regarding pure compounds, azeotropes, zeotropes, and near-azeotropes can be found in the Emerson publication "Introduction to Refrigerant Mixtures," Publication Number 92-81. It is available for download at EmersonClimateCustomer.com.

Evaluation Of Refrigerant Alternatives

Established by the Air-Conditioning and Refrigeration Institute (ARI), the Alternative Refrigerants Evaluation Program (AREP) was directed by an executive committee comprised of senior executives from ARI member companies and was focused primarily on identifying possible alternatives to R-22 and R-502 refrigerants. As part of the program, tests were conducted with 19 refrigerants identified as potential replacements for R-22. Individual test reports issued included compressor calorimeter, system drop-in, heat transfer, and soft-optimized system tests for most of these refrigerants.

AREP also tested many types of compressors, including reciprocating, rotary, screw, and scroll compressors. In addition, system performance was evaluated across a range of applications, including split-system heat pumps, both air- and water-cooled packaged heat pumps, window units, and condensing units. More than 180 AREP reports were approved and released to the public when the committee completed its testing in 1997.

Of the options identified, several HFC refrigerants have emerged as candidates for R-22 replacement. These HFC alternatives were confirmed as viable options through the AREP studies. A summary of the advantages and disadvantages of each alternative is discussed below.

Safety

As the air conditioning and refrigeration industries move away from the relatively few CFC and HCFC refrigerants still in circulation, the issue of safety naturally arises. Of course, safety of new refrigerants is paramount when considering which HFC refrigerant to adopt.

Refrigeration safety issues typically fall into four major areas, including:

Pressure - Virtually all of the new refrigerants operate at a higher pressure than the refrigerants they replace. In some cases the pressure can be substantially higher, which means that the refrigerant can only be used in equipment designed to use it and not as a retrofit refrigerant.

Material compatibility - The primary safety concern here is with deterioration of materials such as motor insulation, which can lead to electrical shorts, and seals, which can result in leaks.

Flammability - Leakage of a flammable refrigerant could result in fire or explosions. In addition, many of the new refrigerants are zeotropes, which can change composition under certain leakage scenarios. Consequently, it is important to completely understand the flammability of the refrigerant blend, as well as what it can change into under all conditions. Using flammable refrigerants exposes individuals and the environment to unnecessary hazards, and Emerson Climate Technologies does not approve of the use of flammable refrigerants in any of its compressors.

Toxicity - During the course of the transition from HCFCs and CFCs to HFCs, some countries have explored and/or applied toxic refrigerant options such as ammonia. These alternatives may offer system performance benefits, but they can also be highly dangerous. It is Emerson's view that refrigerant options like ammonia should not be used, especially considering that HFCs can deliver the equivalent or better efficiency and overall performance. The major refrigerant manufacturers, equipment manufacturers, and safety-standard-setting agencies, such as UL and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), have extensively studied and then rated the safety aspects of proposed new refrigerants according to each of the factors listed above. The intent is to use only refrigerants that are at least as safe as those being replaced.

Transitional Refrigerants (HCFCs)

R-22 has been successfully applied in refrigeration systems of all sizes and temperatures; however, R-22 is an HCFC that is currently being phased out as part of the Montreal Protocol. Phaseout dates for the production of R-22 vary by country, but in the U.S. and Canada, new equipment can no longer be manufactured using R-22 after 2010. Refrigerant manufacturers believe that an adequate supply of R-22 will be available until that time. Figure 2 shows chlorine-free replacement options for R-22.Chlorine-Free Refrigerants (HFCs)

The selection and approval of acceptable long-term refrigerants is a complex and time-consuming task. Many factors must be taken into consideration. The ever-shifting legislative environment, the phaseout of CFCs and HCFCs, the availability of alternate refrigerants, and numerous other factors are just a few of the issues that must be taken into account.Based on these factors, Emerson has cited the following key criteria for evaluating and approving HFC refrigerants for use in Emerson Climate Technologies products:

Regardless of the specifications of individual manufacturers, a refrigerant must have zero ozone depletion and low GWP to be considered a long-term option. These refrigerants can be grouped into three primary classes, according to their vapor pressure/temperature characteristics:

Most of the currently proposed long-term refrigerants are HFCs. The polarity of HFC refrigerants makes them immiscible with mineral oils. As a result, HFC refrigerants must be used with polyolester oil.

HFCs

HFCs, or hydrofluorocarbons, are chemicals used in air conditioning and refrigeration applications. They are nonflammable, recyclable, highly effective, energy-efficient refrigerants of low toxicity that are being used safely throughout the world. HFCs were developed by the chemical industry as alternatives to ozone-depleting CFCs, which are being phased out under the Montreal Protocol, a landmark environmental agreement. The Montreal Protocol, the United Nations Framework Convention on Climate Change (which led to the formation of the Kyoto Protocol), and the Kyoto Protocol were created in an effort to protect the earth's environment.

Technical and Economic Assessment Panel (TEAP) of the Montreal Protocol on Substances that Deplete the Ozone Layer reported in 1999 that HFCs are critical to the safe and cost-effective phaseout of CFCs and HCFCs and are essential substitutes for these products. Likewise, HFCs are necessary both technically and economically for the phaseout of HCFCs in developing - as well as developed - countries. As replacements for less energy-efficient, older equipment, HFC systems conserve energy and reduce the generation of global warming gases at electric power plants. These systems are being used in accordance with responsible-use principles, which range from recovery and reuse of HFCs to design of HFC-producing plants, with the goal of achieving zero HFC emissions.

HFCs offer potential solutions to global warming concerns, energy efficiency, and energy costs without endangering users or workers or requiring extensive equipment modifications and relocations. With proper maintenance and service, energy-efficient products using HFCs reduce carbon dioxide emissions from power plants. Over the past decade, technology advances using CFC alternatives have reduced the impact of greenhouse gas emissions by 80 percent.

An independent third-party report by Arthur D. Little Inc. released in March 2002 stated that HFCs are emerging as the preferred replacement for CFCs and HCFCs because of their desirable characteristics - low toxicity and nonflammability - and their ability to reduce energy consumption.

HFCs are energy efficient, recyclable, low in toxicity, cost effective, and safe to use. They can be used in a variety of applications, including metered dose inhalers, air conditioning, refrigeration, foam insulation, electronic components, technical aerosols, and fire extinguishers.

HFCs are key to operating energy-efficient refrigeration and air conditioning equipment. The more energy efficient a system is, the less CO2 is emitted by power plants to run the system. HFCs reduce energy consumption in many applications. A household refrigerator using HFCs, for example, consumes 10 percent less energy than a comparable hydrocarbon unit. HFC systems often have a lower overall global warming impact than flammable-refrigerant or foam-insulation systems.

Substituting HFCs for CFCs has actually reduced the impact of greenhouse gas emissions, as HFCs reduce total greenhouse gas release. In fact, current technology has reduced greenhouse gas discharged by more than 80 percent since 1990. Projections show that by 2050, HFC emissions will account for less than two percent of potential future contributions for all greenhouse gases, as identified in the Kyoto Protocol.

The manufacture of HFCs requires longer, more complex processes and more sophisticated technology than the methods for making CFCs. Stringent purity standards are necessary for manufacturing refrigerants. Modern HFC plants have sealed systems and closed loop transfers both for internal transfers and for loading and delivery of bulk shipments to customers. Leaks of HFCs in the process are limited to about 0.1 percent of total production, resulting in negligible environmental impact.

The Arthur D. Little report analyzed the cost savings associated with the use of HFCs. Not only do HFCs provide the most cost-effective combination of superior environmental performance and safety, but they also provide significant cost savings in the range of $15 billion to $35 billion, compared to poor-performing and less safe alternatives such as hydrocarbons.

Depending on the country of use, HFC emissions management is being conducted through mandatory recovery and non-regulatory means, voluntary measures and industry-government partnerships. The latter involves engaging jointly in research, communication, and other activities to find new technologies, designs, and processes to manage HFC emissions and to enhance overall product energy efficiency.

HFCs are included among the Kyoto Protocol's six greenhouse gases, and it is believed that they should not be singled out for regulation or restriction. Instead, HFC emissions should be considered only as part of a comprehensive climate-change plan that fully considers collective emissions reductions of all greenhouse gases.

Several HFC refrigerants became commercial reality in 1994, at least for the commercial refrigeration portion of the HVACR industry. Several chemical manufacturers began full-scale manufacture and distribution of chlorine-free refrigerants to replace those containing chlorine. As a result of the availability of HFCs, OEMs began to design equipment specifically for use with the new refrigerants, while components manufacturers began the production of components that had been optimized for use in these unique, new systems. Few, if any, problems have been reported.

In the air conditioning industry, substantial progress has been made toward the phaseout of HCFC R-22. Data compiled by the AREP has been disseminated to the industry for evaluation. Each system manufacturer will be able to choose from the tested refrigerants and select the one that makes the most sense for the type of application it serves.

The HFCs and equipment being produced for refrigeration appear to be satisfactory for these applications; however, there are several areas in which they differ from the refrigerants they are replacing:

One benefit of the new HFC refrigerants is that several of them have demonstrated better efficiency in the equipment in which they are used, as compared to the old refrigerants that they replace. In addition, some of the new refrigerants have lower compressor-discharge temperatures, which should help improve the compressor's reliability and durability.

A negative aspect of POE oils is that they are higher in cost than the mineral oils they replace. As a result, there is research under way to determine if there is any way of solving the miscibility issue of mineral oils in HFCs, perhaps through the use of additives. It is not known at present if this work will be successful.

In summing up the status of HFC refrigerants, virtually all of the experience to date has been positive. Many system manufacturers have converted their products to HFCs, which seem to be well received by their customers. The viability of the new refrigerants has been proven by several years' history of successful operation in a wide variety of systems.

Mixtures

As mentioned earlier, refrigerant manufacturers have been unsuccessful in developing single-component, high-pressure alternatives to CFCs that have zero-ozone-depletion potential, adequate performance, good reliability, and safety. Consequently, the possibility of using mixtures (also called blends, azeotropes, near-azeotropes, and zeotropes) has gained increased attention.

Mixtures have both advantages and disadvantages when compared to pure substances. Mixtures allow the advantage of tailoring the final refrigerant characteristics for superior efficiency, performance, and reliability. Disadvantages of zeotropic mixtures include the following:

Temperature glide - Because the composition of a zeotrope alters during a phase change, there is a slight change in evaporating and condensing temperature at constant pressure. This phenomenon is known as "glide." Most zeotropic mixtures under consideration exhibit low glide. The magnitude of this phenomenon is a little different from similar effects seen with single-component refrigerants due to normal pressure drop within the heat exchanger. As a result, little or no effect on system performance is expected.

Fractionation - Since the components of a zeotropic mixture possess different vapor pressures, under certain conditions they may leak from a system at different rates. As a result, the refrigerant composition may change over time, with a corresponding change in performance.

Zeotropic mixtures currently available in the marketplace with a glide of less than 6 degrees F (3.3 degrees Kelvin) approximate an azeotrope so closely that fractionation should not be a serious problem. The only exceptions to this are systems that use multiple evaporators or flooded evaporators.

To ensure fractionation does not occur during charging, it is recommended that zeotropic mixtures be liquid charged rather than vapor charged. Liquid must be removed from the refrigerant cylinder. It then can be flashed through a metering device and charged into the system in its vapor state. The refrigerant manufacturers' recommendations should be closely followed.

R-134a

R-134a is the first non-ozone-depleting fluorocarbon refrigerant to be commercialized. Developed more than 20 years ago to have characteristics similar to R-12, it is a viable candidate for use in medium- and high-temperature applications in which R-12 has been used. R-134a has been generally accepted by the automotive air conditioning industry because of its low hose permeability and high critical temperature. Domestic refrigerator producers also find R-134a to be a viable refrigerant for their products. R-134a is available from most refrigerant manufacturers.

R-134a has the benefit of being a single-component refrigerant and, therefore, does not have any glide. In addition, the direct HGWP of R-134a is low relative to other options that have been evaluated.

The disadvantage of R-134a lies in its relatively low capacity compared to R-22. To utilize this refrigerant, all of the tubing within the heat exchangers and between the components of a system would need to be significantly larger to minimize pressure drops and maintain an acceptable operating efficiency. This, combined with the greater compressor displacements required, results in a system that will be more costly than R-22 systems today. The heat-transfer coefficient of R-134a is also lower than that of R-22, and tests show that system performance degrades with its use. In summary, manufacturers would need to invest significant time and capital to redesign refrigeration systems from R-22 to R-134a and ultimately would have a design with inherently lower performance or higher cost; therefore, for residential and smaller commercial systems in which R-22 has traditionally been used, we feel R-134a is the least likely HFC candidate.

This may not be the case in larger commercial systems, in which large screw or centrifugal systems have been traditionally used, and refrigerants like R-11 and R-12 were common. Here, R-134a may offer the best solution for a relatively low-investment, simple redesign to HFCs.

Emerson's laboratory and field trials show that the refrigeration capacity and energy efficiency of R-134a are similar to R-12 for medium- and high-temperature applications. At evaporating temperatures below -10 degrees F (-23 degrees Celsius), R-134a loses its attractiveness for several reasons:

With the exception of ozone-depletion potential, Emerson believes that R-134a possesses the same deficiencies as R-12 and represents a step backward for most commercial refrigeration and air conditioning applications. These deficiencies include larger-displacement compressors and larger-diameter tubing compared to that required for use with high-pressure refrigerants.

For customers planning to use R-134a, Emerson has developed product lines for applications above -10 degrees F (-23 degrees Celsius) evaporator temperatures. The expectation is that this refrigerant will not be widely used, except in applications in which the benefits of high-pressure refrigerants cannot be practically achieved, primarily fractional-horsepower and auto air conditioning.

R-404A

HFC refrigerant R-404A has been chosen by equipment manufacturers as the long-term replacement for R-502. R-404A is an excellent low- and medium-temperature refrigerant, due to high energy efficiency and zero-ozone-depletion potential. R-404A is a near-azeotropic blend of HFC refrigerants R-125, R-143a, and R-134a. It is commercially available from numerous sources and is becoming the most popular refrigerant of its class.

R-507

This refrigerant is an azeotropic mixture of R-143a and R-125, with characteristics also very similar to R-502. Emerson compressors developed for R-404A (except for a few hermetic reciprocating models) are also approved for R-507. Both HFCs R-404A and R-507 operate at slightly higher pressures and slightly lower discharge temperatures than R-502.

R-407C

R-407C is a blend of R-32, R-125, and R-134a. Of the higher-temperature HFC options, R-407C was designed to have operating characteristics similar to R-22. The major concerns surrounding R-407C are in its relatively high glide (approximately 10 degrees F) and the efficiency degradation when compared to R-22; however, the use of this refrigerant provides the simplest conversion of the HFC alternatives. We believe that in systems where glide is acceptable, R-407C will become a popular option for manufacturers who want to quickly move to an HFC alternative. In the long run, however, the lower-efficiency performance of this refrigerant may make it a less attractive alternative when compared to R-410A for medium- and high-temperature applications.

Care should be taken when applying R-407C in any applications in which glide can impact system performance by fractionation in flooded-evaporator or multi-evaporator designs. Also, R-407C should not be viewed as a drop-in for R-22 systems or applications. Like all HFCs, R-407C requires the use of POE lubricants, and other system design modifications may be required for R-407C to operate acceptably in R-22 systems.

R-410A

R-410A is one of the most important HFC refrigerants helping the industry meet the 2010 deadline.

Ample research has shown that R-410A is the best replacement for R-22 refrigerants in high-temperature systems - and manufacturers agree. Most major residential air conditioning manufacturers already offer R-410A product lines. With new residential energy-efficiency regulations going into effect in 2006, significantly more air conditioning manufacturers will have implemented the transition to more energy-efficient units, using R-410A.

R-410A has quickly become the refrigerant of choice for use in residential air conditioning applications, because the refrigerant delivers higher efficiency and better TEWI than other choices. The refrigerant also has many benefits that make it an ideal refrigerant for use in commercial refrigeration applications.

There are several distinct operational differences between R-22 and R-410A refrigerants. R-410A operates at 50 percent higher pressure than R-22; however, the higher pressure allows the system to actually run at a lower temperature. Because of these differences, anyone handling these units should receive training on the technical aspects of the new R-410A systems, where they can learn proper joint brazing and critical maintenance tips for this new refrigerant.

R-410A is a near-azeotrope composition of 50 percent R-32 and 50 percent R-125. To date, optimized system testing has shown that R-410A delivers higher system efficiency than R-22. R-410A evaporates with a 35 percent higher heat-transfer coefficient and 28 percent lower pressure drop compared to R-22.

Additional system performance enhancements have been gained by sizing for equal pressure drop and reducing the number of coil circuits needed to increase the mass flux. The higher density and pressure also permit the use of smaller-diameter tubing, while maintaining reasonable pressure drops.

Because systems that use R-410A have been specially designed to use less tubing and fewer coils, R-410A has emerged as a very cost-effective refrigerant. Fewer materials, along with reduced refrigerant charge and better cyclic performance, also contribute to the affordability of R-410A.

R-410A is considered a very high-pressure refrigerant. Very high-pressure refrigerants operate at pressures significantly higher than those normally seen with refrigerants such as R-22 and R-502. They cannot be used as retrofit refrigerants with existing equipment, but only in new equipment (including compressors) specifically designed for them. Existing R-22 compressors cannot meet UL and industry design standards with these higher pressures.

R-152a

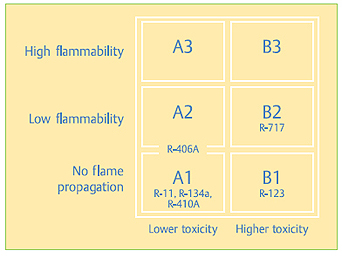

R-152a is thermodynamically similar to R-134aR-152a is chemically very similar to R-134a, but it is very different environmentally. R-152a has a much lower GWP (120 versus 1,300) than R-134a, but is considered ASHRAE A2 – flammable (Figure 3).

R-152a is being considered as an option to replace R-134a in automobile air conditioning; however, due to its flammability, R-152a is not a serious alternative for commercial refrigeration systems.

Halogen-Free Refrigerants

AmmoniaAmmonia (NH3) is widely used as a refrigerant in very large industrial refrigeration plants. As a halogen-free refrigerant, ammonia has the benefit of zero-ozone-depletion potential and no direct GWP; however, its high toxicity generally limits its application to industrial refrigeration applications. In very large ammonia systems, the efficiency is comparable to similar systems with R-22 refrigerant.

Although ammonia is widely available and is a low-cost substance, there are significant challenges to applying ammonia as a refrigerant in commercial refrigeration systems. Ammonia systems have higher discharge pressures than R-22. Oil management becomes a major issue in ammonia systems, since the oils used are typically not soluble in ammonia. The very low-mass flow of ammonia compared to R-22 is an advantage for large ammonia plants, but becomes a challenge in smaller commercial systems. Additionally, ammonia is highly corrosive on copper materials, so refrigerant lines must be steel, and the copper in the compressor-motor windings must be insulated from the gas.

The major drawback of using ammonia in commercial refrigeration applications is its high toxicity and flammability levels. This alone requires unique safety measures that are well beyond the scope of most commercial installations.

Due to its system chemistry challenges, ammonia was not a serious R-22 alternative candidate in the AREP program.

Carbon Dioxide

The use of carbon dioxide (CO2) as a refrigerant has been considered for various refrigeration applications, especially smaller systems. CO2 is given the designation R-744. CO2 is environmentally benign versus other refrigerants, is nonflammable, has low toxicity, is widely available, and is a low-first-cost substance. These are the reasons it was one of the original refrigerants, used nearly 100 years ago. Although thermodynamic performance of a simple CO2 cycle is very poor - 30 to 50 percent worse than HFCs - "poor" refrigerants such as CO2 tend to have very good heat-transfer characteristics and respond well to cycle modifications.

Achieving decent CO2 system performance depends on CO2's substantially higher heat-transfer coefficient (two to five times that of R-22) and the addition of a high-to-low side auxiliary gas heat exchanger or expander. The performance benefits of these factors offset some of the poor cycle efficiency of CO2.

But the higher pressure ratios of CO2, compared to common refrigeration processes, result in special demands on components and compressors. The challenges in using CO2 as a refrigerant revolve around system cost, efficiency, and size.

The pressures created by CO2 present significant challenges in its usage. High side pressures are about 2,500 psi, and excursions can go to 4,000 psi. This is a technical and cost challenge not only for the compressor, but also for the heat exchangers (typically microchannel).

The large pressure ratio creates a challenge in the application of static and dynamic seals in the compressor. Also, pressure vessel requirements increase with the higher pressures.

Theoretically, the efficiency of the compressor should be fairly high using CO2; however, in reality the efficiency of the refrigeration cycle is quite low. Typical cycle efficiency is 40 percent of the ideal refrigeration cycle Carnot, where the coefficient of performance (COP) is 2.5, versus 68 percent (COP 4.2) for an R-134a system at high-temperature conditions. Microchannel heat exchangers are nearly a must, and the system requires a cooler/suction heat exchanger (CSHX). All of these additional components lead to more complex and higher-cost systems. In comparing CO2 with other refrigerants in systems, it is important to ensure that compressors of the same isentropic efficiency are used in the tests and analyses.

The cost impact of CO2 on refrigeration systems is substantial. Due to the higher pressure, modifications are required on the compressor shell, valves, rings, terminal, and seals, as well as the pressure-relief valve and microchannel heat exchanger. Performance implications require CSHX, a discharge-pressure regulator valve, and a low side accumulator to control excess charge. An additional oil separator is required, due to oil circulation and return problems. The bottom line is a 20 to 30 percent higher final cost for performance levels equal to those of an HFC.

In summary, CO2 has many technical and cost challenges. The low efficiency and cycle complexity are the fundamental limitations; however, CO2 may prove to be commercially viable in transport and low-temperature cascade systems, as well as in some heat pump applications.

Hydrocarbons

The push for halogen-free refrigerants has led manufacturers to investigate hydrocarbons as a replacement for R-22. Propane (R-290) is considered as a replacement, because it is a halogen-free substance with no ozone-depletion potential and low direct GWP. Propane is widely available and is a low-cost substance. The operating pressures of a refrigeration system with propane are similar to R-22. Propane has been applied in systems with low charge - less than 150 grams (approximately 10 ounces) - and often outside the U.S.

The disadvantage of propane and all hydrocarbons is that they are highly flammable. System costs increase significantly, due to the required safety measures. Special considerations must be taken for excess pressures and electrical connections, as well as ventilation to prevent flammable gas mixtures. Commercial operators typically do not want to risk the safety-code issues and litigation risks associated with using propane in a refrigeration system.

A "safe" hydrocarbon system would have to be leak proof with special testing, would contain a secondary loop system that would suffer from heat-transfer and pumping losses, and would have to be explosion proof, with special electrical hardware and technician training.

Emerson's policy is one of not developing or selling products for use with flammable or toxic refrigerants for the following reasons:

Key characteristics of these refrigerants are summarized in Figure 4.

Publication date: 12/12/2005

Report Abusive Comment