Figure 1. This heat pump does not have enough refrigerant. You can see the various refrigerant circuits in the coils. (Photo courtesy of Bill Johnson.)

He was trying to figure out what was going on when Btu Buddy asked, “What is the question, Bob?”

Bob said, “You always appear when I am confused. You catch me every time.”

“That could be good,” said Btu Buddy.

Bob then said, “I am lucky that I have you to give me help.”

“Well, what is the confusion, Bob?” asked Btu Buddy.

“I am standing here looking at all of these heat pumps and a few of them have a really different frost pattern. It seems to me that they should all look alike. I realize that this kind of weather will really build frost on heat pumps. But it seems like it should be uniform,” said Bob.

Btu Buddy then said, “Like conditions will produce like frost patterns. There are some things that we should consider before we draw conclusions here. One of the variables would be how long it has been since the heat pump has been running after the last defrost. If it had been 30 minutes, for example, since all of them had been through a defrost cycle, they should all have the same frost pattern, if they were all correctly charged. But suppose one of them were to be undercharged, it would have a frost pattern that would show that the coils were not filled to the correct level of refrigerant. The timers for defrost are not all set at the same time. Look at the unit that you are servicing, you can count the actual refrigerant circuits in the unit. All of them are starved of refrigerant. But that may not be the whole story. If it had just come out of the defrost cycle, we should let it run for at least 30 minutes to see if the coils will fill with refrigerant. The defrost cycle redistributes the refrigerant and we must give it time to get in balance.”

“What would I do if I wasn’t prepared to wait 30 minutes?” asked Bob.

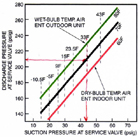

Figure 2. This is a typical charging chart for a heat pump. There are actually two charts, one for the heating cycle and one for the cooling cycle. This one is for the heating cycle. (From Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.)

Bob fastened his gauges to the unit and found the pressures to be low for the conditions. The suction pressure was 30 psig, corresponding to 7°F.

Bob said, “No wonder the coil is freezing. It is running very cold and the humidity is high.”

Btu Buddy said, “Check the charging chart for this unit and see what the suction pressure should be.”

Bob looked at the charging chart in the cover of the unit (Figure 2) and said, “Looks like the suction pressure should be about 42 psig. The outdoor wet bulb is 33° and the indoor dry bulb is 70°. The high pressure should be about 210 psig for these conditions. I think this unit is definitely low on refrigerant charge.”

Figure 3. This is one style of suction line accumulator. Notice that it has a very small orifice in the bottom of the suction tube that allows oil to return to the compressor. It will also allow liquid refrigerant to return to the compressor very slowly so that no damage will be done. (From Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.)

Bob asked, “How am I going to keep the pressure up in my refrigerant cylinder charging vapor in this cold weather?”

Btu Buddy said, “Go to the laundry room with your five-gallon bucket and fill it about two-thirds full of warm water. You should be able to comfortably hold your hand in the water. If it is too hot for your hand, it is too hot. Then, start charging vapor into the system. When the pressure starts to drop, set the cylinder into the water for a few minutes to keep the pressure up. Again, I caution you to just use warm water. You can use a thermometer to check the temperature and don’t let it rise over 105° and you will be safe. Remember all of the days that your refrigerant sat in the back of your truck and it was 100°? The refrigerant cylinder is safe to about 115° so you will be safe.”

Bob charged the system with vapor and the pressures fell in line with the charging chart.

Bob then told Btu Buddy, “That went really smooth. It did take a little time. What other alternatives would I have?”

Btu Buddy explained, “You could have recovered all of the refrigerant and charged it by weighing it in. That is probably the most accurate method. You could also switch the unit to cooling and charge by the superheat method. It has worked well for me. To do that, leave the thermostat in the heating mode and switch the heat pump section over to cooling by removing the four-way coil wire if it is energized in heating or jump it out if it is not energized in heating. Do what it takes to change the four-way valve to cooling and charge using the superheat method. By leaving the unit in heating, the strip heat will start up and will not over-chill the house. The owners will remain comfortable to some extent. This charging method does not take into account the indoor wet bulb temperature, or the load on the evaporator coil, but will get the charge very close.”

Bob then said, “I can’t believe there are so many ways to do a job, and all of them work.”

Btu Buddy responded, “Yes, there are several ways to do many things. It is up to you to use the one that is quickest and keeps the customer comfortable. These decisions will become easier the more you work in the field. You also must ask yourself, where did the refrigerant go. The unit had a low charge. I would suspect that the last service technician did not get the correct charge into the unit.”

Bob said, “The owner said that the unit had not cooled correctly during the last part of the cooling season when it was serviced by another company.”

Btu Buddy then said, “Let’s assume that the charge was not correct and make note of that on your service ticket so the next technician will be aware of what has been done.”

Bob said, “Well, the call is complete now and we have left a paper trail as to what we did. If I am the one to come back, I will be able to review this service ticket. If the charge is low again, I will know to really give the unit a good leak test.”

Publication date:12/21/2009

Report Abusive Comment