Warmer spring weather was here and Bob was beginning to get calls about units that were not cooling. He just received a call from an old customer who said that her unit cools fine during the morning and daytime, but at night, it stops cooling. She then shuts it off for the evening at bedtime and opens the windows.

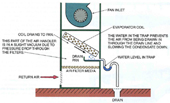

Figure 1. This illustration shows a complete installation, similar to the one discussed in the service call. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (Click on the image for an enlarged view.)

It was 80° outside and the unit was operating. Bob felt the suction line and noticed that it was really cold. He looked in at the compressor and the side of the compressor was sweating. He thought a minute and decided that the unit had too much refrigerant in it and started getting set up to remove some of the refrigerant when Btu Buddy arrived and asked, “What’s up Bob?”

“The unit’s suction line is really cold back to the compressor and it is only 80° outside. It appears to me to have too much refrigerant,” Bob said.

Btu Buddy then told Bob, “Put your gauges on and see what the pressures are running. What do you think they should be running?”

Bob then looked at his temperature and pressure card and said, “The unit uses R-22. I would suspect that the suction pressure would be about 65 psig and the head pressure would be about 260 psig, corresponding to a condensing temperature of about 120° (80° + 40° = 120°). This seems to be a standard efficiency condensing unit and it is about 15 years old. How does that sound?”

Btu Buddy said, “That is some quick thinking on your part. You are getting used to calculating the head pressure. You are about right. Why did you decide on 65 psig for the suction pressure?”

Bob explained, “Well, the home thermostat is set at 70°, which is a little on the cool side, and it is spring. There is not enough humidity in the air to put a humidity load on the coil and the head pressure should be a little below normal because it is not a hot 95° summer day.”

Btu Buddy said, “Those are some good deductions. Now let’s put the gauges on and see what the pressures read.”

Bob fastened his gauges to the gauge ports and noted the pressures to be 51 psig low side and 225 psig high side.

Bob then said, “Well, so much for speculation. Now what?”

Btu Buddy asked, “What would cause a low suction pressure with a low superheat?”

Bob then said, “Well, it looks like there is enough refrigerant in the system. Maybe the coil is dirty, or the filters are dirty. I think I will have a look. The coil is over the furnace in the garage.”

Bob and Btu Buddy went to the coil and Bob felt the suction line at the coil and said, “This line has some ice on it. We either don’t have enough airflow or the coil is dirty.”

Btu Buddy then asked, “What is next for you?”

Bob said, “I am going to check the filter first, then the coil and fan for dirt.”

Btu Buddy said, “That sounds like a good plan.”

Bob turned off the breaker to the furnace, which stopped the whole system, then he removed the cover to the filter and it was clean. The owner had been changing the filter every 60 days and had a record of it written down on a page close by.

Bob said, “Well, I guess we can rule out dirty filters. The owner seems to really keep them clean.”

Bob then removed the cover to the fan housing and took his light and shined it at the fan wheel, and he said, “Look at that fan wheel. It has a lot of dirt caked into the wheel.”

Btu Buddy then said, “If there is that much dirt built up on the fan wheel, you can bet the coil is also dirty. What is going to be your plan of action?”

Figure 2. This coil can be washed slowly and the water should all go down the condensate drain line. Then the drain line should be flushed to push all dirt to the drain. (Click on the image for an enlarged view.)

“That is a good plan, Bob. You are covering all the bases,” said Btu Buddy.

Bob then said, “Now explain to me why the system was not cooling at night.”

Btu Buddy explained, “The system had reduced airflow and the coil was freezing during the running cycle, as you observed. However, the thermostat would satisfy and the coil would thaw between cycles. When evening came, the outdoor air temperature dropped even further, causing the evaporator pressure and temperature to drop to the point that the coil would freeze up all the way. I would suspect that airflow dropped to practically nothing with the coil frozen. There would be no cooling during the evening hours and there would still be some heat load in the house from lighting and other activity. When she shut the system down at bedtime, the coil would thaw overnight and the process would repeat itself the next day. The system seems to have enough refrigerant. Cleaning the fan and coil should solve the problem.”

Bob then asked, “The filters were clean. How did the fan and coil get so dirty?”

Btu Buddy responded, “Typical filters are good for taking out large particles. There is a certain amount of air that goes through a typical hardware store filter. This bypass air is dirty and, over the years, it will build up. Particularly on a wet cooling coil in the summer, it is a super filter. It was a dead giveaway when you found that the fan wheel was dirty. The coil must be dirty also.”

Bob then said, “Well, another day, another lesson.”

Publication date:05/18/2009

Report Abusive Comment