The day was scorching hot and Bob got a call to go to an office building because the air conditioning system was off. It was a water-cooled chiller located in the basement with the water tower on the roof of the building. The refrigerant was R-22.

When Bob arrived, he was met by the building manager who said, “We have been using another service company for several years and they say they cannot get to our call for three days, and we are without cooling. Everybody in the building is hot and irritable.”

Bob said that he would do what he can to get the system back on-line as soon as possible. He explained that all local service companies were busy because of the heat wave, then he went to the equipment room where he found a 100-ton reciprocating chiller that was not running. He looked the system over and saw that the flag on the high-pressure control was out, signaling that the unit was off because of high pressure.

Bob was about to reset the control when Btu Buddy showed up and said, “Why don’t you look at the tower before you reset the control. You may find the problem there.”

Bob said, “I should have known that I was headed in the wrong direction when you showed up.”

They went to the roof and looked at the water tower. The condenser water pump was running and the tower looked clean with clean water running through the tower.

Figure 1. This condenser has dirty tubes. The water returning to the tower from the condenser should be about 95°F. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.)

Btu Buddy said, “That was a good observation. The motor starter for the tower fan is over there. Turn the starter to “manual on” and see if the fan will start.”

Bob turned the fan to on and the fan started so he said, “Well, the fan will run, but it has to be controlled by a water temperature thermostat. I wonder if it is starting the fan. I am going to set the starter back to the automatic position and start the chiller and see what happens.”

Btu Buddy then said, “That is the next logical step.”

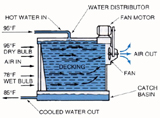

Bob pushed the button and the chiller started up. It had its own gauges for the operator to watch. As they were standing watching the chiller run, all seemed normal. Btu Buddy said, “Watch the thermometers in the condenser water lines. The water from the tower is showing 85°F in and 90° out (Figure 1). What does that tell you?”

Figure 2. This cooling tower is operating at full load, 95°F water in and 85° water out. The condenser for this tower is operating correctly.

Btu Buddy then said, “What is the chilled water side of the system doing?”

Bob looked at the thermometers in the chilled water circuit and said, “The inlet water is 70° and the outlet water is 60°. The chiller seems to have a 10° drop, which is normal, but the condenser only has a 5° rise. It seems that the evaporator is operating at 100 percent and the condenser is only operating at 50 percent capacity.”

Btu Buddy said, “Great observation. You are really catching on.”

Bob said, “Thanks, experience is teaching me how.”

Btu Buddy then said, “Feel the liquid line going to the expansion valve and tell me what you feel.”

Bob felt the liquid line and said, “This line is hot, and it should only be warm.”

Btu Buddy then explained, “The system has a condenser water temperature of 85° entering the condenser and should condense the refrigerant at about 105° with 95° leaving water. It should have about 10° of subcooling, so the liquid line temperature should be about 95° when it is operating normally. What is your observation at this point?”

Bob said, “It looks like the condenser tubes are dirty and not taking the heat out of the refrigerant. Look, the head pressure is up to 260 psig. The high-pressure control is going to shut the chiller off. I think it should be set at about 275 psig. We need to get set up to clean the condenser tubes as soon as possible. I am going to call the shop and ask for someone to bring me the condenser tube cleaning machine and someone to help me clean the tubes.”

Bob called the office and got equipment and help on the way. Then he told Btu Buddy, “I am going to start removing heads from the condenser and maybe we can have this system back on in a few hours.”

Btu Buddy then said, “You are really organizing this job to save the customer downtime. They will thank you for that.”

Figure 3. The man above is cleaning the condenser tubes on a large chiller using a machine that turns a nylon brush and flushes the tube with water at the same time.

Bob said, “In about five minutes we will be ready to start the chiller back up.”

The manager said, “I was afraid you were going to say sometime tomorrow.”

Bob opened the valves and let the water fill the condenser, then he started the condenser water pump and, assured that water was flowing, he started the chiller.

He watched the high-pressure gauge and it settled down at 210 psig. The system was working correctly. He kept observing as he cleaned up the equipment room and picked up all of his tools. In about 30 minutes, the chiller was putting out 45° water and the head pressure was still 210 psig. The system was performing normally.

The manager came back to the equipment room again and said, “Thanks for getting this job done in a reasonable time. I noticed that you worked right through the lunch hour to provide service for us. I called the restaurant down on the corner and you and your helper have the lunch of your choice on us. Thanks for doing such a good job.”

As Bob got in his truck and the helper got in his truck to leave for lunch, Btu Buddy said, “You really did a great job here today. It will be noticed by management and they will reward you for doing good work.”

Bob then said, “Thanks for all of your help. It feels good when a job goes as good as this one.”

Then Bob remarked, “I wonder why those condenser tubes were dirty? The tower had a water bleed off system and the water was clean.”

Btu Buddy said, “You don’t know if the other company did regular maintenance on the system. The water could have been really dirty for a long time, then the other service company could have cleaned up the tower and not checked to see if the condenser was performing correctly.”

Bob then asked Btu Buddy, “Suppose I were to start up the system in the spring. What should my procedures be for assuring the condenser is in good shape for the season?”

Btu Buddy then suggested, “Let’s meet for lunch tomorrow and we will discuss spring startup for water-cooled equipment.”

Publication date:08/18/2008

Report Abusive Comment