HVAC systems account for over 35% of a building's energy costs. They are often difficult to design, fabricate, install, and manage with traditional processes and tools. An uncoordinated effort from several contractors across mechanical and energy systems can lead to multiple challenges in the construction stage.

Mechanical contractors that use Building Information Modeling (BIM) experience significant improvements in schedules and costs, greater system efficiency, fewer errors and better fabrication. BIM processes and tools bring powerful capabilities and help HVAC contractors to innovate and deliver better.

A study by Dodge Data and Analytics for Sheet Metal/Ducting contractors and HVAC contractors reveals that HVAC contractors have gained the following benefits by adopting BIM.

- Reduces waste by 50%

- Increased labor production by 50%

- Improved cost performance by 43%

- Better installation quality and reduced errors by 36%

This article discusses the top 5 benefits that BIM offers to HVAC contractors.

Challenges faced in adopting BIM

Some of the challenges that HVAC contractors face while using BIM include:

- Employee training

- Lack of staff

- High investment and overhead costs for resources and BIM technology

- Software costs

Top 5 advantages of BIM for HVAC contractors

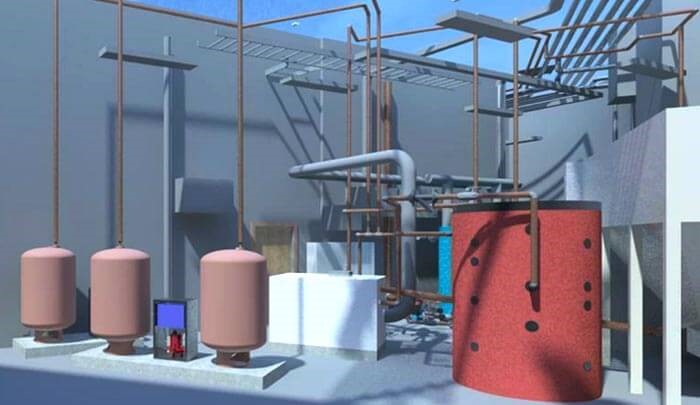

Using 3D modeling tools to create and adopt data-rich digital models through real-time analysis, simulation, calculations, and visualization extends HVAC design and performance during construction and operations. A recent Dodge Data and Analytics finding shows 65% of mechanical contractors produce a BIM model of the work they install onsite.

The top benefits of HVAC contractors using BIM are as follows:

1) Collaboration. Project stakeholders who do not communicate early are bound to experience rework issues as workflows are fragmented and people work in silos. BIM-based workflows allow quick decision-making and cut down re-engineering, iterations and rework for HVAC contractors.

Multi-trade contractors have witnessed a 49% reduction in requests for information, or RFIs, in the construction stage.

Europe based BIM consultants needed a clash-free Revit MEP model for an institutional facility. They partnered with a reliable BIM service provider to gain an efficiently designed 3D Revit model and first time right deliverables. The clash-free and coordinated HVAC model enabled them to make informed decisions to save on costs.

2. Coordination. The use of 3D BIM visualization drives greater coordination and promotes clash-free design for HVAC contractors to reduce uncertainties. A variety of mechanical components and their connections with other project elements have always been a pain for mechanical contractors until BIM arrived.

Installing mechanical components in tight onsite spaces can lead to clashes or costly redesign. Contractors can leverage BIM-enabled workflows to ‘see things better’, shed light on minute installation details, and lower RFI count.

With the rest or the construction industry wholeheartedly adopting BIM, contractors in HVAC have to make their shift. Data shows 61% of HVAC contractors in the US receive a model from a BIM provider to begin their work.

Trade contractors have experienced a significant reduction of 27% in RFIs with the adoption of BIM software.

3. Higher productivity. 2D HVAC drawings extracted from coordinated and interference-free 3D models up productivity. Revit-based model authoring helps contractors leverage bespoke mechanical families that can be customized and modeled through accurate dimensions, specs, material types, etc.

Automation tools for Revit that include Dynamo, APIs, and Macros speed up the modeling process with higher accuracy to achieve improved productivity. Precision shop drawings and IFC drawings help mechanical contractors fabricate accurate mechanical systems and equipment, followed by seamless onsite installation.

84% of mechanical piping contractors have observed greater productivity through BIM adoption, including 78% of users for sheet metal/ducting

4. Reduce waste. As mentioned earlier, stringent project timelines and budgets challenge contractors. Material waste from inaccurate and inefficient HVAC fabrication reduce profit margins significantly.

Mechanical contractors using BIM-based workflows can leverage the power of prefabricated components and equipment to diminish manufacturing waste and streamline onsite installation.

Over 85% of the firms have witnessed a positive impact of BIM usage through lower material waste reinforced by prefabrication.

5. Innovate. You can help future-proof your business with advanced BIM capabilities. Greater use of BIM for synchronization and improved layout can enhance coordination activities. Designing and installing HVAC components in the right layout enhances productivity, boosts construction speed, and elevates installation accuracy.

Advanced BIM processes and tools can help mechanical contracting firms save on material wastage, labor costs, and improve performance, and quality.

BIM adoption in HVAC sheet metal

It is difficult for HVAC contractors to gain a seamless installation and fabrication process without BIM due to technology evolution. A centralized model will become a crucial deliverable to manage a project as every piece of data resides in the 3D model.

With the host of benefits that BIM offers to HVAC contractors, such as coordination, clash-free installation, offsite fabrication, sequential construction, and enhanced project management, contractors BIM holds the key to the future.

.jpg?1675271241)

Report Abusive Comment