"The Romans logged celestial activity and tried to predict future events," said Welsh, who was speaking at the National Conference on Building Commissioning. "The concept has remained the same from the beginning: record information regarding a physical property, analyze that information, then make predictions or draw conclusions from the patterns observed."

The technology has advanced through hand logging to strip chart recorders and benchtop loggers, which were commercialized in the early 1980s, he said. "A good-quality, 20-channel benchtop logger cost about $5,000, which equates to a cost of about $250 per channel.

"The true stand-alone logger is what we have today," he continued. They are available "with just about every communication option imaginable." Some are even emersion capable. With a USB port, a technician can place the logger inside ductwork for as long as he needs to record conditions there, plug it into his or her PC later on, and collect the data.

Some modern units contain only internal sensors; others can have external sensors attached. Some have built-in LCD displays, and still others connect to PDAs for downloading and reading in the field. Models can be linked together to form a data acquisition network, and located "virtually anywhere so as to be located in, or right next to, the environment that is to be monitored," Welsh said.

Data can be downloaded via USB, radio, or optical systems to a PC. "The data analysis software available from the logger provider can be extremely powerful and flexible," Welsh said. "A single logger can have three or four sensors and cost less than $100, for a cost of about $25 per channel. This makes it economical to have many stand-alone data loggers distributed in the environment running few or no wires."

TROUBLESHOOTING WITH DATA

The two most common reasons for data logging in building commissioning are to demonstrate performance or troubleshoot the system, Welsh said.Troubleshooting applications include:

Performance demonstration includes:

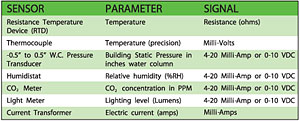

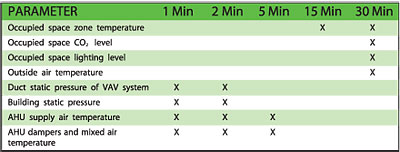

"Data loggers are designed to measure and record a variety of characteristics of the physical environment," Welsh said. The following are typical physical characteristics that may need to be trended to troubleshoot or evaluate performance of a building system in a commissioning application. "This list, though fairly extensive, is not intended to list all characteristics that may need to be logged," he said.

DATA LOGGER OPERATION

Welsh said that certain steps have to be taken regardless of the particular style of logger being used:Planning: "Careful planning will be the difference between a successful logging project and one that requires excessive data manipulation at the end - or, in some cases, that has to be done over. You'll waste a ton of time if you don't sit down and plan what you're going to do."

Welsh recommended developing a data logging plan (DLP) that outlines your goals and approach.

"Start with the end in mind," he said. "The DLP should outline specific goals to be achieved or a problem statement outlining the circumstances requiring troubleshooting and hence, data logging and reporting."

The DLP should include goals and/or problem statement, a list of the building automation system (BAS) trend-logging capabilities, list of environmental parameters to be measured, accuracy/calibration requirements, sample intervals for all logged points, sensor locations, logging period (start-stop date-time), and a communication plan (to explain the intent, impact, and duration of the study to the building owner, facility, staff, or occupants).

"If people see a little box with wires, they might get all freaked out" if you haven't explained what's going on, Welsh said.

Deployment: Once the loggers are configured, the stand-alone data loggers need to be deployed into the environment to be evaluated. The deployment process includes:

Recovery: At the end of the logging period, the stand-alone loggers are retrieved and data is recovered from BAS trend logs and stand-alone loggers. The recovery process also includes backing up the data.

"Prior to erasing the data off the loggers or before leaving the site, it is recommended that the data be backed up," Welsh said.

"Inexpensive, portable storage devices can be plugged into USB ports that work well for the backup and for transferring the data files from the BAS trend logging system.

"Don't forget: Do your backup. That's a lot of money you've invested."

USE THIS KNOWLEDGE WISELY

"Data loggers are powerful analysis tools that can be used to evaluate complex building relationships and solve control problems," Welsh said. However, with such a broad range of possibilities, "Data loggers and the subsequent analysis of thousands of points of data can also be a huge waste of time if improperly applied."You can inundate yourself in data, swim in it for hours, but not get anywhere. Log smart." Standard procedures and techniques can help ensure that the data logging tools are used optimally.

Sidebar: Your Best Logger

Make sure you get the type of sensor that best suits your application, Welsh said. "Each type has various advantages and the best one will depend on the specific application. Generally the most universally useful units for building commissioning are the types with both internal and external sensors." Also, consider the following selection criteria:Engineering units. "For loggers that accept an analog signal from a generic device such as 4-20 mA or 0-10 vdc, the ability to program and record data in actual engineering units is an extremely valuable feature." Welsh said.

Cost. "Everyone has a budget. Generally it will be an exercise in finding the best bang for the buck, the unit with the most capabilities at the least cost."

Size. "Most units are so small that this is likely not an issue, particularly for building commissioning applications," Welsh said. However, some applications (e.g., food processing) require the units to be processed along with the food inside the containers.

Mounting. "This can be important depending on your application," Welsh said. "For instance, you may need a watertight enclosure. Many units simply come with a hole in the case for hanging via a screw or a wire. Some units come with a magnetic back, which is generally very handy for HVAC work as there is almost always some steel around."

Accuracy. There are three basic areas of accuracy: the sensor, the logging device receiver, and the number of bits the logger uses.

"Each type of sensor has a built-in level of error so that the signal they produce is off by that amount regardless of the measuring device," Welsh said. "Any receiving device, whether a logging device or just a readout, has a built-in level of error in its ability to take an analog signal and convert it to a digital signal. These first two errors combine to form the overall input error."

Calibration and traceability. Will there be a requirement to have the ability to field calibrate the instruments, will they require factory calibration, or will they have no calibration capability? "Many of the applications for building commissioning do not require extremely high accuracy," Welsh said, "so depending on the specific needs, having no calibration capability may be a good trade-off to low cost."

However, "even without the ability to calibrate a device, its calibration can and should be verified in the field by subjecting it to a known physical standard."

Real-time readout. Some units come with an LCD screen for real-time reading, if you need it. In building commissioning, it typically isn't a necessity, Welsh said. "Some units can be connected via the downloading cable and the data stream monitored via software on a portable computer."

Recording indicator. This feature shows you that data is indeed being recorded and logging is occurring.

Recording interval. Small recording intervals are needed to capture events that change rapidly. "The shorter the interval, the more data points are taken and the faster memory is used up," Welsh said.

Storage capacity. This is measured by the total number of samples the device can record. "Most systems can now log into the tens of thousands of samples so this is usually not an issue, but should always be considered in the selection process."

Memory type. Most systems use an internal memory chip; the logging device is plugged directly into the computer for data download. Some loggers use flash memory cards.

Software. The software is used to configure, launch, and recover data from the logger. It also can be used to view, analyze, and report on the data. It is important for logger software to have good exporting capabilities so that other software can be used for the data analysis.

Connectivity. The most common connection method is the USB cable, which is usually sufficient for most applications, Welsh said. Some units use infrared or other wireless protocols. Units that use flash memory don't require a cable. Some units plug directly into a computer or PDA.

Networking. Some data loggers can be networked, allowing the devices to be configured, launched, monitored, and uploaded from one point.

Starting options. There are several options for starting a logging period; instantly after download - at a predetermined time, event-driven, or via a manual input (pushbutton).

Data overflow options. When the logger's memory is full there are two options, overwrite the oldest data or stop logging. Logging systems should have both options.

Batteries. Some units come with replaceable batteries; others have "10-year" nonuser-replaceable batteries.

Battery status indicator. Some data loggers include a battery status indicator either on the unit, via software, or both.

Publication date: 06/12/2006

Report Abusive Comment