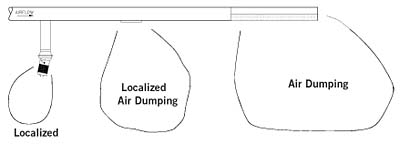

Since exposed duct systems generally result in lower construction costs, there has been a surge in the use of exposed-type terminal outlets. Fortunately, there are several types of terminal outlets that allow different methods of airflow distribution. Most commercial and industrial air distribution applications require one of the following types of methods: localized or concentrated distribution, air dumping (displacement ventilation), or a combination of the two, which we will call "localized air dumping." Figure 1 shows the airflow patterns of each type of terminal outlet discussed. The terminal outlet chosen should match the airflow distribution requirement.

We will examine some of the features of several types of terminal outlets that use the three methods of air distribution discussed.

Localized Distribution

Most industrial plants use ducted air distribution with low-level discharge for the most efficient heating and cooling of work zones located in large, open areas. The low-level discharge is accomplished through the use of drops from the main air system to the work zone.To effectively use low-level distribution for heating and cooling, positive control of the velocity of the ducted air over the worker is required. Because of the natural variables associated with each individual and the continuing change in ambient conditions, this important velocity level cannot be a preset figure.

Workers may control the discharge pattern by setting the opposed-blade outlet damper (called a vari-damper) in an open, intermediate, or closed position. The discharge patterns range from a direct, full-velocity flow to a gradually widening pattern with lower velocity.

There are models available with a swivel ball joint that allows directional control in any direction up to 20 degrees from the vertical axis.

Air Dumping

Many air distribution applications involve supplying air to critical processes without creating a noticeable draft. For example, many university labs require low air discharge velocities in the room. These short throw (distances where the air reaches 100 fpm) applications could benefit from the use of an air dumping type of outlet.Diffusers that fall in this category are fabric ducts and perforated metal ducts (diffusers). The characteristics are low throw and radial discharge, meaning you wish to have slow air discharging perpendicular to the duct centerline. When a perforated metal duct has internal orifice plates, the resulting diffuser assembly can perform similarly to a fabric duct.

Perforated metal diffusers used for air dumping generally have holes of about 1¼8 inch in diameter and an open area of about 20 to 30 percent. These diffusers should not be used in applications where forced air is required, where the volume exceeds the capacity of the diffuser, or where the air supply is not filtered and contains lint or felting types of dirt.

One type of perforated metal diffuser, the Type SP Duct-D-Fuser, also manufactured by McGill, has a radial throw of 5 feet if the velocity entering the diffuser is 500 to 800 fpm. McGill is currently working on a Web-based program so that a diffuser can be sized online. The program will exclude orifice plate sizes, as this information is proprietary and will be supplied when the diffuser is shipped.

The common perforated metal air dumping diffuser has a 360-degree flow pattern along its entire length. Other common configurations include a 90- and 180-degree discharge. These diffusers are sized as a continuous perforated diffuser with internal orifice plates to promote radial airflow. Individual perforated ducts with solid duct in between may be used for long runs of duct as long as there are orifice plates or dampers between perforated sections. This type of diffuser is ideal for harsh environments, as the perforated metal body can be wiped down and will not tear.

The most common perforated metal air dumping diffuser is the round assembly with orifice plates. The radial discharge can be any angle up to 360 degrees, although angles of 90 degrees, 180 degrees, and 360 degrees are most common.

Perforated metal diffuser de-signs have an average surface discharge varying from 5 to 50 cfm per square foot of surface area. The air distribution pattern from the diffuser is dependent on entering air velocity. Typical entering velocities into the diffuser range from 500 to 1,200 fpm. As a general rule, the ideal entering velocity is 500 to 800 fpm, and should never be higher than 1,800 fpm. The static pressure required to operate this type of diffuser is unusually low; it is always less than 0.10 inches water gauge. This is primarily due to the fact that the perforated metal body is 20 percent to 40 percent. The low operating pressure may surprise those familiar with fabric ducts.

Unlike most perforated metal diffusers, fabric ducts have a much lower percentage open area, which results in a higher static pressure to operate for a given entering velocity.

Localized Air Dumping

For many years the rectangular register or grille mounted on a rectangular tap has been the predominant configuration for localized air dumping. In recent years, however, there has been a movement towards the flush-mount terminal outlets that are more aesthetically pleasing. All of these outlets allow local control by the strategic placement of the outlet on the trunk duct, while air dumping is accomplished by varying the number and size of these outlets.The grilles and registers used for localized air dumping have attributes of both localized and air dumping terminal outlets. This means that these types of terminal outlets have the feature of strategic air placement by locating the units where needed, and the feature of the massive air dumping by locating several units in close proximity to each other.

Some of these units have opposed-blade damper assemblies mounted behind a perforated screen or fins. This allows for volume control.

There are many types of grilles and registers that fall into this category of localized air dumping, including the perforated flush-mount grille with an opposed blade damper (OBD), and fin-type flush-mount with OBD. Each of these types may be ordered with OBD assembly, which results in a less costly outlet but does not provide volume control.

Gierzak is the mechanical engineer and laboratory supervisor for McGill AirFlow. He can be reached at jgierzak@mcgillairflow.com.

Publication date: 12/08/2003

Report Abusive Comment