Bob received a call from the dispatcher on a Friday morning. The customer’s complaint was an overall overheating of his building. The building was a four-story office building.

Bob arrived at the building and talked to the manager who said, “We arrived this morning and the entire building was hot and keeps getting hotter.”

The manager led Bob to the basement where there was a boiler. The weather was beginning to get cold, so heating was required. Bob went into the room where the boiler and controls were located. It was a hot water boiler and the water outlet temperature was 160°F. The boiler was really putting out the heat. Bob decided to go to one of the areas that was too hot and it was really hot. He looked at the thermostat’s thermometer and it showed 82° and the thermostat was set at 72°. He went to another area and the same was true.

Bob went back to the basement and was looking confused when Btu Buddy appeared. Bob explained what he knew and Btu Buddy said, “First, turn off the heat to the building until you can get the picture. Turn off the boiler and then the hot water pump. No more heat will go out to the building.”

Bob turned them off and Btu Buddy said, “Look at the building’s control sequence. It is in that blueprint that is framed over on the wall.”

Bob looked over the print diagram and said, “This system has pneumatic controls. I remember some things from school, but I have never worked on one of these systems before.”

Btu Buddy then said, “It seems to be a total system problem since the whole building is complaining. Good thing they have windows they can open. If this were an electrical control system with a complete system failure, what would you look for first?”

Bob said, “I would look first at the power supply. The power is on and OK.”

Btu Buddy then asked, “What is the power supply in a pneumatic system?”

Bob said, “Air controls the system.”

“Well,” Btu Buddy asked, “what is the air pressure?”

Bob looked at the system gauge and said, “There is no air pressure. Maybe that is the problem.”

Btu Buddy said, “What is the source of the air pressure?”

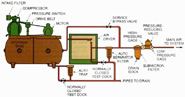

Figure 1. This pneumatic control compressor and control assembly represents what Bob discovered on this call. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Btu Buddy suggested, “Check the inlet filter and see if it is completely stopped up.”

Bob removed the filter and it was not stopped up. Then he said, “This compressor is defective. It must be changed.”

Btu Buddy then said, “Good diagnosis. Would there be any way to put the system controls back into automatic control?”

Bob said, “I didn’t even think of that. This is Friday and if we order a compressor this afternoon, the quickest we can get it here would be Monday.”

Btu Buddy asked, “Isn’t all you need is an air supply for a few days?”

Bob said, “Yes, I believe nitrogen would work as good as air. It is dry and not expensive.”

Btu Buddy asked, “What are you going to do?”

Figure 2. Illustration shows a nitrogen cylinder and regulator arrangement that can be used for pressure. (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Btu Buddy said, “That sounds like a plan that will work.”

Bob connected the nitrogen cylinder to the system and set the pressure to 20 psig and watched the system controls take over. He turned on the hot water pump and then the boiler. It would take a while for the whole building to adjust, but it was in the process.

Bob said, “I have a question: Why did the building go to heat and not to cool?”

Btu Buddy explained, “The system controls have a fail safe option built in. If loss of air caused the system to go over to cool, and the air pressure were lost on a freezing weekend, the building might freeze up. Pipes may burst and all kinds of damage could occur. It is best to have an overheated building than a frozen building.”

Bob then said, “There are a lot of angles and reasons to designing building systems.”

To be continued in the December 20, 2010 issue.

Publication date:11/22/2010

Report Abusive Comment