At some point or another, you are bound to have an experience with Trimble’s SysQue, and sheet metal workers everywhere would do well to know at least why the sheet metal software is so popular.

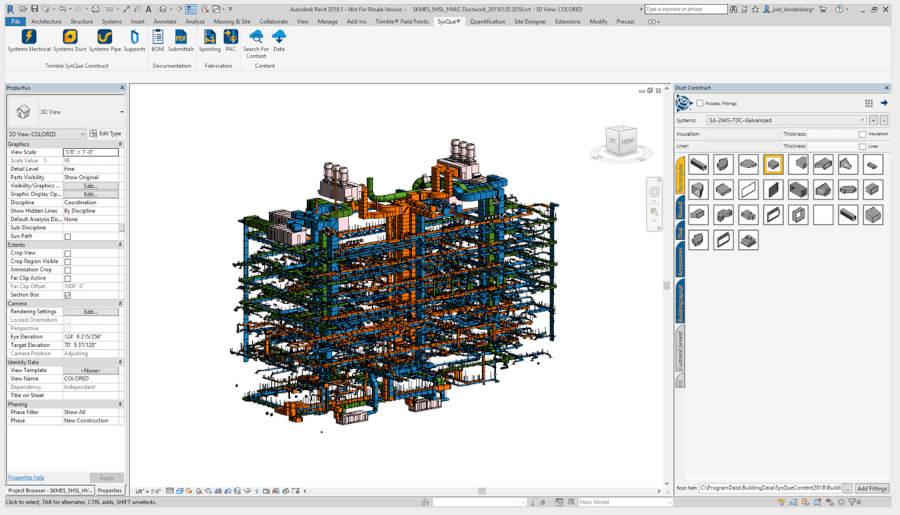

In a nutshell, Trimble’s SysQue is a Revit plugin that enhances a sheet metal shop’s detailing process.

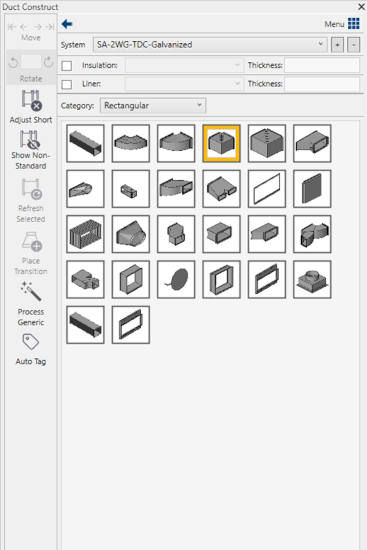

As an add-on software, SysQue sits right on top of Revit and utilizes Trimble’s database of Constructible Content, formally known as Building Data. The advantages of the constructible content over your standard out of the box Revit families (RFAs) is the level of detail shown as you draw. Meaning, the fittings that you are drawing accurately match the fitting in real life which is a requirement for any BIM project requiring a LOD 350 or greater.

The value to this is that your foreman in the field can install the fittings you have coordinated and downloaded them with full confidence, knowing that every little detail has been accounted for — down to the type of hanger that will be installed in the field.

On the shop floor, sheet metal workers may not work directly with SysQue, but they will need to be able to use and understand the products created from the software, such as shop and spool sheets, to help assemble and prefab ductwork.

What Is Trimble SysQue Trimble SysQue

For mechanical contractors, Trimble SysQue enables the coordinating and design of mechanical, sheet metal, electrical, and plumbing systems using Revit, with the added bonus of native Revit pipe, valve, and fitting families. For sheet metal shops, the ability to create spool drawings for the fab shop and pre-fabricate duct assemblies is key.

SysQue’s streamlined system has been a mainstay for larger mechanical contracting operations. However, Trimble does offer other programs that compliment SysQue throughout the whole construction process.

For sheet metal shops, Trimble offers another product called FabShop, which is their CAM (computer aided manufacturing) software. FabShop allows all the fittings that were coordinated and detailed to be downloaded directly to your shop’s plasma or laser machine for fabrication.

Additionally, if you are considering moving to SysQue from a CAM system, you do not have to replace because SysQue is compatible with CAM software such as Autodesk’s Fabrication.

For commercial sheet metal operations, SysQue is often the first step in streamlining a shop. However, like any sheet metal software, it is the process that makes software a powerful tool.

A lot of sheet metal shops don’t realize this and get frustrated thinking that their sheet metal software is meant to be a cure all. My processes are what have help make me successful in this industry, and sheet metal software is very much about knowing what you need to make your own success.

Trimble SysQue As A Sheet Metal Software

Sheet metal shops need programs like SysQue to help better streamline their process. As a stand-alone product, shops will benefit from the fact that they are able to participate in the 3D BIM coordination process. It also allows for the fittings to be downloaded directly to the shops plasma or laser machine and saves the time from manually inputting each piece. When paired with the other software, it allows a company to run leaner by:

- Granting sheet metal shops the ability to estimate projects more accurately and in a shorter amount of time

- Create a just in time delivery schedule for when parts of the project will be downloaded, fabricated, shipped and installed

- It gives the shop a forecast on what items will need to be fabricated and on what day so they can make sure they have sufficient materials to complete the project

- Track fabrication and installation times to see where the bottlenecks are

- Export hanger and penetration details to be geographically placed in the field giving a more accurate layout.

SysQue also has built in tools that help with certain tasks such as hanger layout and spool sheet creation.

If it seems like some sheet metal machinery brands work lock and step with other sheet metal software, you’re probably right. A good example of this is the interoperability Trimble SysQue famously shares with Mestek’s laser and plasma cutting tables. However, there are other sheet metal machinery brands, that can do the same with some small added programming.

My experience and opinion when it comes to Trimble SysQue is this: as a sheet metal software, I’ve known about SysQue and have been following the developments of the software since 2012. I have tested their software and like what they have to offer especially now that they have been acquired by Trimble.

For myself, the price point is a bit high compared to the other options out there, and there are plenty of great options out there. SysQue definitely has some good features. Overall, I would rate SysQue an 8 out of 10 as there are some things that are not quite there yet. But to be fair, there is no software on the market yet that is 100 percent complete.

Alternative Sheet Metal Software to Trimble SysQue

There are other sheet metal software options to choose from, but it really comes down to budget, options and comfort level in using the software. Here’s an overview of a few of those software options.

Applied Software – eVolve

Applied Software software is also an add-in to Revit, but the biggest difference is that it utilizes ITMs. ITMs are components native to Autodesk’s Fabrication database

This allows former Fabrication CAD users to import the exact database that they were using in CAD directly to Revit with the exception of a few items. The use of ITMs mean that each fitting accurately represents the real-life model much like Trimble’s Constructible Content. However, unlike SysQue, the database is tied to fabrication so the parts that are used in Revit are not native RFA files.

ASTI has built in tools similar to SysQue to help with automated tasks. All around, eVolve is about the cost as SysQue, with really great customer service and support.

MetaLab – PractiRev

PractiRev is a sheet metal software is similar to Trimble SysQue in that they both have databases that are hosted on Revit. They have their own Revit family (RFA) fittings similar to Constructible Content, just not as many at this time.

MetaLab also helps build custom content for their customers. They have built-in tools to speed up certain tasks, and they are higher tiered when it comes to price. However, MetaLab also includes additional software to help with workflow. Add that with excellent customer service and great tech support, and you will quickly appreciate what you're paying for.

AutoDesk – Revit

The third alternative option to Trimble SysQue is to learn about AutoDesk and build your own components within their platform. They have programs like Dynamo and Forge that can help sheet metal companies create their own content and tools.

The upside is you are not paying a third party for software. The downside is that it takes a lot of time and trial and error because the software is always updating with added features. Or, if you can wait five more years, in my opinion, I think AutoDesk will continue to develop their fabrication system to work better with Revit. Fingers crossed.

Report Abusive Comment