With good reason, Advance Cutting Systems named its newly released fiber laser the “Evolution.” In terms of cut quality, fiber lasers are considered “the next step in HVAC cutting” after high definition plasmas, explains Clint Ray Jr., national sales manager at Advance Cutting.

“Everyone needs something, for lack of better words, ‘yesterday,’” he says. “They need ‘just-in-time production.’” Fiber laser cutting technology has evolved to do the work.

Fiber lasers can cut up to 10 times faster than plasma cutters; they don’t smoke as much, and cuts produce a smooth edge — requiring little to no finishing before assembly. Although the technology has been around for some time, price has been the largest factor in preventing the widespread use of fiber lasers in the duct fabrication industry. Now as the use of the technology becomes more affordable, machinery brands are bracing for demand.

“When plasma cutters first came out, they were around $200,000. So, the technology on the laser side is coming down in price, and it’s making it more attractive, especially to some of the bigger shops who invest in a $300,000, sometimes $800,000 coil line,” Ray explains. “Most laser cutters are going to be geared toward your larger shops, manufacturers. Or, you will have the contractor who says they are going to go ahead and invest in it because they want to buy into the future.”

Call Clint

On the fence about laser cutting technology? Contact Clinton Ray, Jr., of Advance Cutting Systems, at 205-337-8520 or clint@advancecutting.com.

Laser cutters are mostly priced by the strength of the wattage, which is what produces the laser beam. The higher the kilowatt, the faster you can cut. For 1.5 kilowatts, fiber laser cutters start around $200,000, increasing as high as 10 kilowatts. Comparatively, the average plasma or CO2 laser table today can cost $50,000 or less.

Beyond wattage, higher end machine brands for manufacturing such as Amada and Trumpf include robotic automation in their fiber laser packages. “That’s where they take a different step than what we do,” says Ray. “That’s when you are getting into the big, big shops where they are more about running lean than anything.” But when it comes to the precision of the cut, wattage is wattage.

“If I cut a part off my machine, and they cut a part off their machine, I would say 99.9 percent of the time you can’t tell the difference,” says Ray. The more important distinction between laser cutters is open v. closed enclosures, he explains.

Enclosures protect users from the laser beam during production, which can cause instant blindness if the beam were to reflect or refract during operation. For that reason, most fiber lasers used in metal fabrication come with enclosures. An exception to this is Mestek Machinery’s fiber laser, the Laser-Max 1.5, which is specifically engineered for the duct fabrication industry. Patented technology prevents the laser from bouncing during production, allowing the machine to be safely used without an enclosure and to be coil fed.

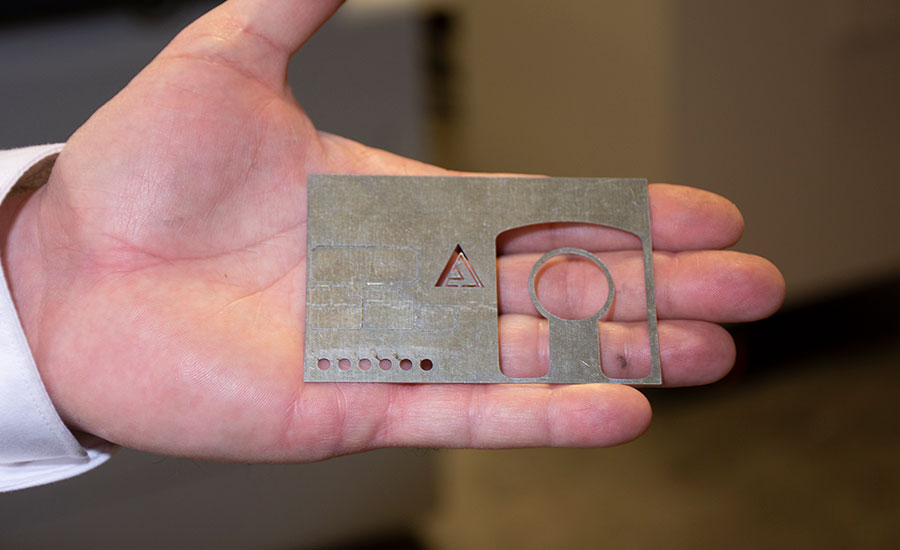

Clint Ray Jr., national sales manager at Advance Cutting Systems, operates the Advance

On the shop floor, it is important to remember that laser cutters are not plasma cutters. Distinctions in speed and production between the two machines allow contractors to take advantage of shifting workflows and retiring older machines, says Ray.

“That’s where the Evolution is,” says Ray. “For the bigger mechanical contractors, that’s where they are going to start seeing a big difference in that they don’t have to have three or four plasmas.”

He adds, “I could put in a laser, and they could keep one of their plasmas as a backup or run specialty on. The other three machines I’ve replaced with this one laser, and it’s going to do the work of four or five machines.”

At top speed, plasma cutters can cut 600, 700 inches a minute. The problem with that says Clint is they are not reliable.

Evolution E3015-B Fiber Laser Cutting Machine.

“You are changing consumables at every other sheet. Realistically you are going be cutting plasma at probably 400 on the thinner stuff 450 inches a minute on the thinner stuff,” he says. “On the thinner stuff, lasers are cutting at 2500 to 3000 inches a minute.” Of course, there’s the caveat of acceleration and deceleration for the machine.

“You just don’t start off at 3000 inches a minute. You have to ramp up and ramp down,” he explains. “But when you look at the big picture of it, that’s where a fiber laser is cutting at a lot faster than a plasma.”

This story originally appeared in the September 2019 issue of SNIPS magazine.

Report Abusive Comment