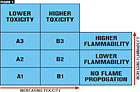

Figure 1.

SAFETY

It is a very safe refrigerant and has a safety classification of A1. This means that it is not flammable and is very low on toxicity (See Figure 1). A classification of A1 is the safest, where a classification of B3 would be the most toxic and flammable.MOLECULAR STRUCTURE

R-134a is not a refrigerant blend. It is considered a pure compound and has only one molecule present consisting of carbon (C), fluorine (F), and hydrogen (H) (See Figure 2).

Figure 2.

ENVIRONMENTAL ISSUES

Because R-134a has no chlorine in its molecule, it has a zero ozone depletion potential (ODP). Its global warming potential (GWP) is relatively low at 0.27.TEMPERATURES, PRESSURES

R-134a has a very similar pressure-temperature relationship when compared to R-12 (See Figure 3). However, at the lower temperature, R-134a has a bit lower pressures than R-12. Also, at higher temperatures, such as 65°F, R-134a has a bit lower pressure when compared to R-12. Otherwise, their pressure-temperature relationships closely compare.

Figure 3.

CAPACITY

Both R-134a and R-12 have comparable capacity relationships (See Figure 4). When comparing capacities of R-134a to R-12, R-134a suffers some capacity loss when used as a low-temperature refrigerant. This can be a 6 percent capacity loss when compared to R-12 at the lower-temperature applications.However, at the higher-temperature applications, there is a 6 percent increase in capacity when compared to R-12. Again, because of this phenomenon, R-134a is a good medium- and high-temperature refrigeration and air conditioning refrigerant.

It is not usually used in low-temperature applications. R-134a often operates with a very low pressure, if not a slight vacuum, at these lower temperatures.

Figure 4.

EVAPORATOR TEMPERATURE APPLICATION

At about a -15°F evaporating temperature, R-134a starts to fall into a vacuum. These lower pressures at the lower temperature application cause higher compression ratios and low efficiencies, not to mention the added stress put on the system’s compressor.LUBRICANT

Stationary R-134a systems use synthetic polyolester (POE) lubricants. The automotive industry uses polyalkylene glycol (PAG) lubricants with R-134a. R-134a is insoluble, and thus incompatible, with mineral oils used in many refrigeration and air conditioning applications today.Publication Date:07/06/2009

Report Abusive Comment