Frost is simply frozen dew. Usually on lower temperature refrigerant applications, the suction line and part of the compressor's head will get cold. The part of the compressor's head that gets coldest is where suction vapors enter before they are compressed.

These parts often get cold enough to reach the dewpoint of the surrounding air. When the air comes into contact with the cold suction line and compressor head, water vapor in the air is cooled to its dewpoint and condenses on the suction line and compressor head. (See Figure 1.)

When this condensed water vapor reaches 32 degrees F, it becomes frost. Frost is simply condensed water vapor or dew that has reached 32 degrees or below.

System Specifications

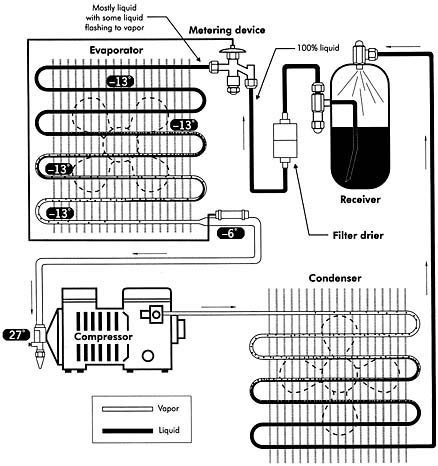

The system discussed here is a low-temperature commercial refrigeration application operating with 7 degrees of evaporator superheat and 40 degrees of compressor superheat. The refrigerated box temperature is 0 degrees with an evaporator temperature of -13 degrees. It is an R-404A system.With an evaporator temperature of -13 degrees and the system having 40 degrees compressor superheat, the temperature of the refrigerant coming into the compressor would be 27 degrees (-13 degrees plus 40 degrees). The 27 degree temperature coming into the compressor is lower than the surrounding air's dewpoint, and it is also lower than the freezing point of water, so the dew on the suction line and compressor's head will form frost.

These frost lines are completely normal for this low-temperature application refrigeration machine. (Refer to Figure 2 for a system diagram with temperatures.)

Compressor Flooding Or Slugging

Because the system has a compressor superheat of 40 degrees, there is no reason to worry about whether the compressor is flooding or slugging. To review, flooding is liquid refrigerant coming back to the compressor's crankcase during a run cycle. Slugging is liquid refrigerant or oil actually entering the compressor's cylinders and/or valve arrangement and being pumped. Again, because the system has superheat at the compressor of 40 degrees, flooding and slugging cannot exist.In order for slugging or flooding to occur, the compressor would have to be experiencing no superheat. In other words, the temperature coming into the compressor would be the same as the evaporator temperature (-13 degrees). This would indicate that there was no compressor superheat and liquid refrigerant was entering the compressor.

In either scenario, whether the system does or doesn't have compressor superheat, both the suction line and compressor's head would still be frosted. This is why it is of utmost importance for technicians to measure superheat at both the evaporator and compressor - to check for possible slugging or flooding.

Measuring Total Superheat

Compressor superheat (total superheat) is all of the superheat on the low side of the refrigeration system. Compressor superheat consists of evaporator superheat and suction line superheat.A technician can measure total superheat by placing a thermometer, thermocouple, or thermistor at the compressor inlet and reading the temperature. A pressure reading will also be needed at this same location.

Consider the example previously noted for an R-404A system with a low-side pressure taken at the compressor of 21 psig, or -13 degrees, and a compressor inlet temperature of 27 degrees. The pressure gauge reading on the low side of the system (21 psig) tells the technician that there is a -13 degree evaporating temperature. The compressor superheat calculation is shown in Figure 3.

As you can see, the compressor superheat is 40 degrees. It is possible to have a TXV adjusted to control the proper amount of evaporator superheat at the coil and still return liquid refrigerant to the compressor at certain low-load conditions. It is recommended that all TXV-controlled refrigeration systems have at least 20 degrees of compressor superheat to ensure that the compressor does not see liquid refrigerant (flood or slug) at low evaporator loads.

Compressor superheats from 20 degrees to 30 degrees are recommended to ensure adequate compressor cooling and preventive liquid control to the compressor. The TXV, however, should be set to maintain proper superheat for the evaporator. Following these instructions should ensure that the compressor always sees refrigerant vapor.

Tomczyk is a professor of HVACR at Ferris State University, Big Rapids, Mich., and the author of Troubleshooting and Servicing Modern Air Conditioning & Refrigeration Systems, published by ESCO Press. To order, call 800-726-9696. Tomczyk can be reached by e-mail at tomczykj@tucker-usa.com.

Publication date: 05/03/2004

Report Abusive Comment