Operating Costs

A consulting engineer who owned a Phoenix-area office building was interested in lowering the operating costs associated with ventilating the building in the dry Arizona climate, while maintaining indoor air quality (IAQ) for his employees and other tenants.The building was originally equipped with a variable air volume (VAV) system, complete with direct digital control (DDC) of the VAV boxes, variable-frequency drives (VFDs), and staged compressors on the rooftop unit. With the existing DDC system, he was able to call up the system on his computer, monitor control parameters at his discretion, and make changes to building set points and box settings.

As his business continued to grow, and the first-story tenant space was leased out, the building owner found he needed more flexibility in responding to the fluctuating energy demands imposed on the building during the day. After investigating DCV as a control strategy, he immediately recognized the benefits that zone level control of ventilation rates could achieve.

The engineer decided to invest in DCV technology to reduce costs and meet ASHRAE Standard 62-99. The existing Carrier system was upgraded with Carrier ComfortLink Rooftop Controllers, ComfortID VAV terminal box controllers, and DCV control routines based on levels of carbon dioxide (CO2). A Carrier CO2/temperature sensor controlled both room temperature and ventilation.

Since DCV algorithms are already built into the ComfortLink and ComfortID systems, retrofit of the system was as easy as "plug and play." Over 12 months, the air quality was noticeably improved, and the owner saw a 38 percent improvement in HVAC-related energy costs.

How It Works

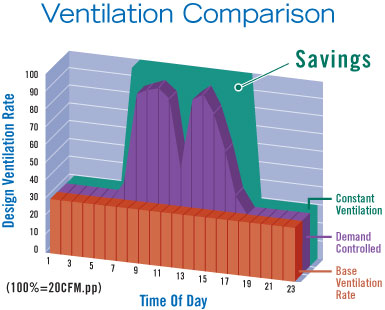

DCV measures the amount of CO2 in the building's environment and uses that information to modulate outside air levels to maintain proper ventilation without costly overventilation.Buildings using this ventilation control strategy remain in compliance with the requirements of ASHRAE Standard 62 and en-joy substantial energy savings over buildings ventilated at a fixed rate during occupied periods.

Up until ASHRAE Standard 62-2004 was adopted, there was little available material to reference when establishing the base ventilation rates. Over the last few years, a rule of thumb has been established that the base ventilation rate for most spaces should be 20 percent to 40 percent of the design ventilation rate.

In practice, the base ventilation rate is most often driven by the amount of fresh air needed to balance building exhaust and provide positive pressurization. ASHRAE has released Standard 62-2004 that established base ventilation rates for sources in terms of cfm per square foot for various occupancy categories.

Compared to a fixed ventilation approach, DCV offers considerable advantages.

Since it is based on CO2, DCV does not affect the design ventilation capacity required to serve the space - it just controls the operation of the system to be more in tune with how a building actually operates. Overventilation is avoided while outside air requirements and IAQ are maintained.

Numerous studies show that using a DCV versus fixed ventilation can result in operational energy savings being reduced by up to 80 percent, with a range of 5 cents to one dollar per square foot. System paybacks can range from a few months to two years and are often substantial enough to help pay for other system or building upgrades.

The payback from CO2 DCV will be greatest in higher density spaces that are subject to variable or intermittent occupancy (such as theaters, schools, retail establishments, meeting rooms, and conference areas).

This ventilation standard can be implemented in applications ranging from single-story buildings with one rooftop unit to high-rise office buildings utilizing central cooling plants and air handlers. It is versatile enough that it can be used just in certain areas of the building, where load is only provided on an occasional basis.

Thom Sellars is territory service manager for Carrier Commercial Service. For more information, visit www.commercialhvacservice.carrier.com.

Publication date: 06/13/2005

Report Abusive Comment