*The following originally appeared in the April 2006 issue of Snips. Figures used have not been adjusted for inflation.

Many shop owners and managers know that it takes a well-equipped facility to be competitive in the HVAC construction and sheet metal forming market, but that’s only one requirement.

You also need the correct machines and tools, and to use them efficiently.

In the selection of a shop machine or tool, a prime consideration is whether its use will require more than one person. A basic principle of efficient shop labor is the “one man, one job” concept.

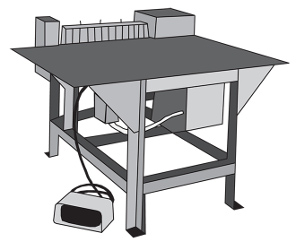

A machine that requires two people to operate it may not justify the expense of the labor costs. An example of a one man, one job machine is a hand-operated drive-slip turner compared with a newer table model power-drive turner.

A table model power-drive turner is much more labor efficient when turning drive edges on larger pieces of ductwork that would require two workers on the old style hand-drive turners.

Before buying any equipment, ask yourself if the task that the machine or tool is being purchased to do is one that the shop should be doing at all.

Justify the use

Can you instead buy the items from a vendor and use your employees to fabricate products that are more profitable? A good example is ductwork connectors. Most shops simply cannot compete with the efficiency of the high-volume, well-equipped connector makers. The bottom-line cost analysis of shop-fabricated versus purchased connectors must consider the lost revenue that would have been generated by applying that labor to making duct and fittings.

Some argue that a lower-paid shop worker can cut up scrap and produce the connectors cheaply. The problem with this is two-fold: First, ample scrap in the correct gauges isn’t always available; neither is low-cost labor. In reality, it’s common for full-fledged mechanics to use prime sheets, sheets that cost almost as much as the formed connectors could have been purchased for. It certainly makes economic sense to have a lower-paid worker use up scrap during a slow period, but only to supplement a good stock of purchased connectors.

Is the machine being considered versatile and capable of performing numerous operations on a variety of fabricated products or is it limited by design?

A table model power-drive turner is more efficient to use when turning drive edges on large ductwork. A hand-operated drive turner would require two employees to work it, violating the “one man, one job” concept.

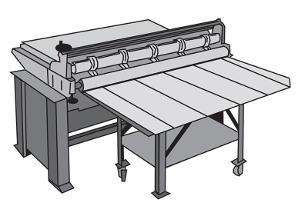

Such is the case with certain power brakes. Some power brakes are primarily duct brakes, designed to very efficiently make 90-degree male flanges and “L” section bends on light-gauge, straight-duct sections. They are cost effective and do a good job. However, there are some medium-duty hydraulic brakes available that not only make light-gauge male flanges and “L” sections efficiently but also can handle industrial-type metals down to 12 gauge. These have a wide range of upper dies available, including sectioned dies for box and pan fabrication, “gooseneck” dies for difficult, close bends and to make architectural shapes of almost any type.

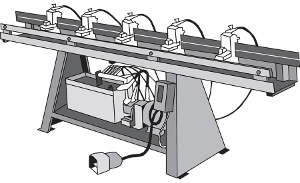

This freestanding beading machine will bead 16-gauge metal. However, some models listed as 18 gauge may have difficulty beading the heaviest steel still considered 18 gauge.

Ensure equipment is versatile

Versatility is great insurance for a timely return on investment. The rule here is to not purchase equipment that has limited usefulness by design. Instead, buy equipment that will perform efficiently on a variety of your existing product-fabrication tasks and can even open the door to the possibility of expanding your overall product base.

Often, several machines can perform the same task. However, there may be great variances in the operating speed of these similar machines. Roll formers are a good example. Generally speaking, the faster a roll-forming machine runs, the more productive it will be. This is a very important consideration as roll-forming machines vary widely in processing speeds, and almost all ductwork requires a significant amount of roll forming on the longitudinal seams and even on other edges such as standing seams and connectors.

The speed of roll-forming machines varies greatly, and can impact your profit on the fabrication labor on the product as clearly indicated on the roll-forming productivity chart.

Heavy-duty service

Always purchase a heavier duty machine than your normal applications require. Like household appliances, shop machines are often rated at the extreme edge of their capabilities, and realistically will not hold up forever at that level. That’s why it is always prudent to purchase a machine rated at least one gauge heavier than needed and preferably two gauges heavier.

Return on investment, commonly called “ROI,” is your bottom line on any equipment purchase. In reality, four factors will determine your ROI on any equipment:

- The initial cost of the machine, including installation and operator training.

- The anticipated productivity increase.

- Your business’ hourly wage rate.

- Your annual volume of the task performed by the machine. The following is an example of the ROI for a new or used partial coil line through the notcher.

This hydraulic duct notcher is a perfect example of how purchasing extra power up front can dramatically increase productivity and profits. These units are available in 20-gauge residential duty or 16-gauge commercial duty. However, this 16-gauge model is capable of notching two light-gauge patterns together, which doubles the productivity on residential or commercial work.

Most owners expect it to take about five years for their machine purchases to pay off. Unfortunately, predicting the exact payback period is not easy. On the other hand, when the four factors discussed earlier clearly indicate a payback period of five years or even less, the question of making the investment becomes much easier to answer.

Here’s a hypothetical example of a partial coil line purchase:

- New purchase price of a through-the-notcher machine: $125,000

- Annual volume of full, straight joints: 300,000 pounds

- Shop-labor cost: $35 per hour

- Productivity rate with partial coil line: 250 pounds per hour

- Manual productivity rate: 110 pounds per hour

- Direct labor costs with coil line: $42,000 (1,200 man-hours)

- Direct labor costs with manual equipment: $95,454 (2,727 man-hours)

- Gross direct-labor savings with coil line: $53,454

- Minus annual coil line burden costs: $22,500

- Annual direct labor savings with coil line: $30,954

Roll-forming machines speed-comparison table

| Machine Speed | Time per 1,000 feet of seam | Time for 10,000 feet of seam |

|---|---|---|

| 25 feet per minute | 40 minutes | 400 minutes |

| 35 fpm | 29 minutes | 286 minutes |

| 45 fpm | 22 minutes | 222 minutes |

| 65 fpm | 15 minutes | 154 minutes |

| 70 fpm | 14 minutes | 143 minutes |

| 100 fpm | 10 minutes | 100 minutes |

At a labor savings of $30,954 annually, the ROI payback period will be a little over four years ($125,000 divided by $30,954)

There’s an old saying about tools: “There is nothing more expensive than a cheap tool, and there is nothing cheaper than an expensive tool.”

This definitely also applies to machinery. Shop machines are a classic example of getting what you pay for. However, used machines and tools, purchased from a reputable and technically qualified sheet metal equipment dealer, can help equip a smaller volume shop with a limited budget.

Such dealers have the ability to completely refurbish a good, solid piece of used sheet metal equipment and bring it to like-new condition. Many offer a 30-day or longer guarantee after such reconditioning. Your shop equipment budget can be stretched by up to 50 percent by seeking out high-quality used equipment from reputable vendors.

Report Abusive Comment