Matt Lattanzi

These new performance requirements apply to residential single-phase air conditioners and heat pumps that are less than 65,000 Btuh, small duct high velocity and through-the-wall products are excluded. Additionally, there are new minimum standards for single-phase weatherized (gas packs) and non-weatherized forced air furnaces below 225,000 Btuh. Also included in this agreement are provisions for individual states to adopt new construction building codes that exceed the federal minimums.

Without a doubt, this is an enormous change for the HVACR industry, and it will have a significant effect on contractors. For example, many contractors believe in and have adopted selling strategies based on the good, better, best sales approach. This approach has been utilized successfully for years and can still be used effectively in the future. With these new standards, however, it may be time to consider some adjustments in how the industry defines the good, the better, and the best.

SELLING IN THE SOUTH

Traditionally in southern climates, good, better, best is often defined based on SEER levels. In the southern states, these three levels might be 13, 14, and 15 SEER respectively. This may work well in today’s environment, but consider what happens when the federal minimum becomes 14 SEER. Good, better, best becomes 14, 15, and 16 SEER. All three tiers are more expensive than before; however, the better and best options just became significantly more expensive because 15 and 16 SEER equipment typically contains two-stage compressors, variable-speed fans, or requires larger footprints to reach these efficiency levels.Good, better, best with 14, 15, and 16 SEER, however, may still work in some markets with the right consumer. This will depend on the consumer and the payback for the higher SEER equipment in a given market. For the consumer who is sensitive to the initial system cost - or where market conditions make the payback marginal for the higher SEER equipment - here is an alternative selling strategy.

The first tier - good - can be 14 SEER, better is 14 SEER plus a high-end thermostat, and best is 14 SEER plus a high-end thermostat and UV light. There are multiple combinations of IAQ products that can be used under this approach depending on the market and the consumer. In fact, upselling with IAQ products makes good sense regardless of federal minimum standards. IAQ accessories give you the ability to upsell based on comfort levels, energy savings, and the consumer’s health concerns, such as asthma or allergies.

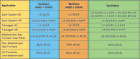

Table 1.

SPECIAL CONSIDERATIONS FOR THE NORTH

The northern region also has its own challenges in the regional standards world. Good, better, best is often defined there as 80-percent AFUE, 90- to 92-percent AFUE, and 95-percent-plus AFUE. In today’s environment, the difference between good and better is significant - 80-percent AFUE versus 90-percent AFUE. Fast-forward to regional standards and this makes the new minimum 90-percent AFUE. Good, better, best becomes 90-percent AFUE, 92-percent AFUE, and 95-percent-plus AFUE. Differentiation between good and better is significantly diminished, so this selling strategy will require some modifications.Here are a couple of alternative selling strategies that should be effective depending on the local market:

• Differentiate based on heat staging and variable speed. For example, good might be a single-stage 92-percent or 95-percent AFUE furnace, better could be a 95-percent two-stage and a fixed-speed furnace, and best could be a 95-percent two-stage, variable-speed furnace. This strategy gives contractors the ability to upsell based on comfort and sound levels in addition to energy savings.

• IAQ accessories can also provide viable options. For example, good might be 92-percent AFUE, better could be 95-percent AFUE with two-stage and a high-end thermostat, and best could be 95-percent AFUE with two-stage and a high-end thermostat with a humidifier. There are many combinations and approaches with heat staging, variable speed, and accessories. AFUE is still usable, but to a significantly lesser extent.

• Another approach could be to provide service/maintenance contracts or extended warranty protection plans. For example, good might be 95-percent AFUE, better could be 95-percent AFUE and a two-year maintenance contract, and best could be 95-percent AFUE with a two-year maintenance contract and an extended 10-year labor plan with the warranty.

Beyond modifying the good, better, best approach, another consideration for the northern region is repair versus replace. When the new regional standards come into effect on May 1, 2013, it is predicted that many consumers will opt to repair their 80-percent AFUE furnaces as opposed to replacing them with 90-percent-plus AFUE condensing furnaces that have a higher price tag and installation cost. The savvy contractor should do everything possible to demonstrate the benefits of utilizing a 90-percent-plus AFUE furnace instead of repairing the 80-percent furnace - especially if market conditions indicate a short-term payback.

That being said, the industry can still expect a significant amount of repairs. Contractors should be aware of this upcoming trend and be prepared to deal with the need for additional service technicians, increased parts inventories, and more.

Additionally, in the northern region, 90-percent AFUE furnaces will likely create some installation challenges, particularly when replacing an existing 80-percent AFUE furnace.

These non-condensing furnaces are commonly vented through B vent, which is galvanized sheet metal pipe, while 90-percent-plus AFUE condensing furnaces are commonly vented through PVC or CPVC. If replacing an 80-percent AFUE furnace in the northern region, it will be necessary to install PVC or CPVC pipe to accommodate venting the furnace.

The existing B vent chimney cannot be utilized because the flue gas is too cool, which will likely lead to condensation issues inside the chimney. This installation could be problematic if there is no easily accessible route for the new PVC venting system. Contractors may have to install several elbows to facilitate venting the furnace, and the trouble with elbows is that each elbow reduces the overall allowable vent length. Additionally, a common application for 80-percent AFUE furnaces is to share the B vent chimney with a domestic hot water heater. Once the 80-percent AFUE furnace venting is removed from the B vent, this could cause the B vent chimney for the hot water heater to become oversized. A new chimney or hot water heater may be required.

MORE CHANGE? BRING IT

As an industry, HVACR has become very adept at handling change - first 13 SEER, then tax credits, then R-410A. These new regional standards will be one more rough patch to navigate. Of course, by planning now for the change to come, contractors can come out on the other end with a stronger business and keener selling strategies. With change comes opportunity, and if the industry prepares for and embraces change, then HVACR should be in a better position to prosper. Here’s hoping for smooth sailing ahead.Publication date:01/25/2010

Report Abusive Comment