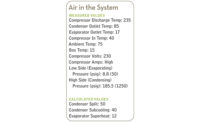

The main reason for pulling a vacuum on a system is to rid it of unwanted gases, mainly air and water vapor. Air, being a noncondensable, will get trapped in the high side of a refrigeration system because the condenser’s liquid seal (subcooled liquid) at its bottom prevents the air’s passage. The system’s head pressure, condensing temperature, discharge temperature, and compression ratio will now elevate, causing unwanted inefficiencies because of the reduced condensing surface area. At these elevated temperatures, oxygen in the air will react with the refrigeration oil to form organic solids. Removing air or other noncondensable gases from a system with a vacuum pump is known as degassing a system. Removing water vapor from a system is known as dehydration. In the HVACR industry, the process of removing both air and water vapor are referred to as evacuation. So, (Degassing + Dehydration) = Evacuation.

Water Vapor

Water vapor, on the other hand, will cause more serious problems to systems. As we know, all air contains water vapor. If for some reason air is present in the system, water vapor will also be present.

Water vapor can cause ice crystals at an expansion valve’s orifices. However, sludging problems due to the formation of acids will cause more serious system problems due to water vapor in the system. Pinhole leaks in coils caused from environmental factors or poorly manufactured coils are also ways moisture can get inside a HVACR system.

Water vapor can also enter a refrigeration system either through a leak; poor service practices; or it may be generated from the chemical reaction of oil, refrigerant, and excessive heat. Corrosion, acids, and sludge from the mixture of water vapor, excessive heat, oil, and refrigerant can seriously damage a cooling system. HVACR systems that have been exposed to an atmosphere of high relative humidity or use very hygroscopic oils like Polyolester (POE) lubricants may hold more moisture than other systems. These systems may need more

evacuation time.

Also, larger systems can hold larger amounts of moisture because of their large internal volumes and also may need more evacuation time because of this. Whatever the case, it is the vacuum level, not the time on your wristwatch, that tells the service technician the deep evacuation is complete.

Corrosion and Sludges

When moisture, heat, and refrigerant are present in a refrigeration system, you can bet, after a short period of time, acids will form. Refrigerants, such as chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and hydrofluorocarbons (HFCs) either contain chlorine, fluorine, or both and will hydrolyze with water forming hydrochloric and hydrofluoric acids and more water. POE oil with high concentrations of moisture will break down into its original components of alcohol and sulfuric acid. Once acid is formed, corrosion will occur on most of the system’s metals (See Figure 1). When this acid is carried through the system and mixes with the system’s oil, globules of sludge will form along with organic acids and oil decomposition products. Sludge is nothing more than a tightly bound mixture of water, acid, and oil. One point that has to be understood is that many refrigeration oils are very hygroscopic, meaning they will attract moisture readily. Refrigerants are also attracted to refrigeration oil because of the oil’s low vapor pressure.

When considering (Moisture + Acid + Oil) = Sludge, this means that refrigerant and water vapor will be attracted to the oil, and all three will mix and be soluble in one another. Sludge will severely breakdown the oil, reducing its lubricating abilities and causing serious mechanical system damage. If any mechanical parts have corroded from acids, small particles from the corroded parts will be carried in the sludge.

These sludges and solids tend to build up in the hottest point of the system: the discharge valve seats. The valves will no longer seat properly and valve leakage will occur. Sludge can exist as minute slimy or sticky solids; powdery solids; or thick, slimy, and oily liquids. Technicians must realize in order to avoid corrosion and sludging problems in cooling systems, moisture must be kept out through good service practices and an effective preventive maintenance program.

Sludging and corrosion will cause expansion devices, filter/driers, and strainers to plug and malfunction. So, once moisture is in a cooling system, the only sure way to rid the system of its presence is with the proper deep-evacuation procedures. However, once sludge is formed, standard cleanup procedures using oversized driers specified for sludging problems must be followed. Vacuum pumps are simply not designed to remove solids like sludge. By all means, deep-vacuum procedures will not take the place of liquid-line or suction-line dryers because of the vacuum pump’s inability to remove solids.

Evacuation Practices

Clean vacuum pump oil and unrestricted flow from the HVACR system to the vacuum pump maximizes evacuation speed. Clean and pure vacuum pump oil has a very low vapor pressure. A vacuum pump can only pull as deep as the vapor pressure of its sealing oil. The vacuum pump oil is a liquid seal between the vanes and the cylinder walls of all two-stage rotary vacuum pumps. When moisture enters the vacuum pump sealing oil, it reduces the oil’s capability of maintaining a low micron seal. As the oil becomes saturated with moisture, its vapor pressure rises. This, in turn, raises the vacuum level that can be achieved by the vacuum pump. The oil must be changed as its gets cloudy or dirty to remove the initial contamination or the rate of evacuation will slow and a deep vacuum will never be reached. A micron gauge is the only true indicator as to when the oil needs to be changed. The vacuum pump will pull at a slower rate, and the micron gauge will not reach deep vacuums with contaminated oil.

A vacuum pump needs the maximum flow to pump at its full capacity. Removing Schrader valve cores and core depressors in service hoses and using as many ½-inch-or-larger-diameter hoses will provide more evacuation channels and less resistance to flow. A Schrader core can cover 90 percent of the internal diameter of the access port. A Schrader valve core removal tool allows the service technician to remove Schrader valve cores during an evacuation process. The tool also allows the Schrader core to be replaced after the evacuation is complete.

Micron Gauges, Hoses, and Manifolds

A ¼-inch service hose will only allow a vacuum pump to pull at 0.8 cfm, regardless of the vacuum pump’s cfm rating. Never use ¼-inch hoses for HVACR system evacuations. Using 3/8- and ½-inch hoses greatly reduces the resistance to flow from the HVACR system through the vacuum pump. Always ensure the connecting equipment from the HVACR system to the vacuum pump is vacuum-rated to the capability of your pump. A rotary-vane vacuum pump’s capabilities are 20-100 microns.

Avoid using manifold gauge sets for pulling a vacuum because they increase the opportunity for leaks. Also, many manifold gauge sets and hoses offer a lot of restriction to flow from the HVACR system to the vacuum pump. It is not necessary to have a manifold gauge set involved in the evacuation process. Evacuation accesses from both the high and low side of the HVACR system can be done with large diameter hoses coming from the system (See Figure 2). These large-diameter hoses are vacuum-rated and connect to the vacuum pump.

Also, a wireless, digital, Bluetooth micron vacuum stub gauge connected to the HVACR system can be used (See Figure 2). There is no need for gauge hoses or a gauge manifold when evacuating a system.

All micron gauges should be located on the HVACR system as far as possible from the vacuum pump. (A free app for this wireless, digital technology can be downloaded by searching “ION Viewer” in Google Play.)

Accuracy

The Bluetooth gauge is a stand-alone micron vacuum gauge that offers extended functionality, including wireless remote vacuum measurements, a rate of change display, and custom alarms. A wireless, digital vacuum gauge can measure from atmosphere pressure (760,000 microns) down to 1 micron with a +/- 5 percent reading accuracy and a 1-micron resolution.

It is critical that all measuring devices used have a high degree of accuracy, which is key to reducing the total potential margin of error. The degree of accuracy is directly proportional to the operating efficiency of the system. The total margin of measurement errors is the sum of errors in all the measuring devices used for measuring system parameters. HVACR efficiency standards have been increasing steadily over the years, so there must be accuracy in measurement when installing and servicing these systems. The accuracy of measuring devices is critical in today’s society. High- and low-side system gauges are also available with remote, wireless, digital, Bluetooth technology.

Publication date: 11/3/2014

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment