Superheat

What is superheat?

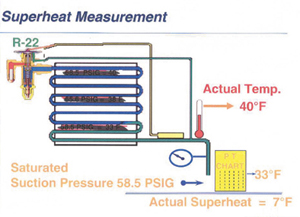

Superheat refers to the number of degrees a vapor is above its saturation temperature (boiling point) at a particular pressure.

How do I measure superheat?

Superheat is determined by taking the low side pressure gauge reading, converting that pressure to temperature using a PT chart, and then subtracting that temperature from the actual temperature measured (using an accurate thermometer or thermocouple) at the same point the pressure was taken.

Why is it important to know the superheat of a system?

Superheat gives an indication if the amount of refrigerant flowing into the evaporator is appropriate for the load. If the superheat is too high, then not enough refrigerant is being fed resulting in poor refrigeration and excess energy use. If the superheat is too low, then too much refrigerant is being fed possibly resulting in liquid getting back to the compressor and causing compressor damage.

When should I check the superheat?

The superheat should be checked whenever any of the following takes place:

Note: The superheat should be checked with the system running at a full-load, steady-state condition.

How do I change the superheat?

Turning the adjustment stem on the TXV changes the superheat.

|

|

Subcooling

What is meant by subcooling?Subcooling is the condition where the liquid refrigerant is colder than the minimum temperature (saturation temperature) required to keep it from boiling and, hence, change from the liquid to a gas phase.

The amount of subcooling, at a given condition, is the difference between its saturation temperature and the actual liquid refrigerant temperature.

Why is subcooling desirable?

Subcooling is desirable for several reasons:

Quick Facts is courtesy of the Flow Controls Division of Emerson Climate Technologies (formerly Alco Controls). For more information, visit www.emersonclimatecontractor.com.

Publication date: 06/13/2005

Report Abusive Comment