Ultrasound is a well proven and respected diagnostic tool routinely employed for weld and flaw detection in critical applications such as aviation, aerospace, military, and nuclear power. Yet, while improvements in instrumentation have moved this technology into other areas such as manufacturing and quality control, its benefits to facility managers, plant engineers, and technicians as a diagnostic and predictive tool are still widely unknown and underutilized.

Many Advantages

As a nondestructive method, UT offers obvious advantages over cutting out pipe for metallurgical inspection. It is nonintrusive, accurate, reliable, safe to both building and inspection personnel, provides immediate results, requires no system shutdown, and is extremely cost effective. Depending upon the measurement technique, degree of testing, and data analysis method used, ultrasound can produce a general assessment of building piping condition, provide direction for capital projects, or focus in on a specific area of concern.Such advance information is becoming more valuable as the former "run to failure" mode of operation moves toward one where all possible vulnerabilities of an HVAC or process operation are known and monitored, and where long-term planning has replaced unexpected failures and emergency repairs.

Establishing the condition of an aged piping system becomes especially important due to its critical function in any HVAC building environment, and due to the wide variety of problems which can potentially develop.

Greater Corrosion Problems

Though not often recognized by building owners and operators, the corrosion threat to most piping systems has increased significantly over the past 20 years. This is due to less effective chemical corrosion inhibitors, more corrosion susceptible steels, less tolerant engineering practices, and yet, always greater operating demands.Compared to steel pipe installed in the 1950s, where a 1-2 mil per year (MPY) corrosion rate could be reliably assumed, most open water cooling or process water systems average 3-5 MPY or greater today. Low pressure open water cooling tower systems, once exclusively constructed using schedule 80 or extra strong pipe until the early 1970s, are now installed with schedule 40 and even ultra thin schedule 10 as a means to cut material and installation costs.

Less Effective Controls

Chemical treatment programs are far less effective in all but the most strictly maintained and highly monitored piping systems, yet still fail to equal the corrosion control of decades ago. At the same time that microbiological agents are being recognized as a significant factor in many high corrosion rate scenarios, stricter environmental regulations have not only cut the effectiveness of many chemical biocides, but have reduced their active half life as well.Regular monitoring for corrosion and remaining system life is often lacking for all but the largest or most critical building or process operations. Even when employed, most testing methods provide little information relative to the true corrosion activity existing within the piping system.

Corrosion Coupon Limitations

Corrosion coupons, the most commonly used and widely accepted method of corrosion monitoring, exclude most of the environmental forces normally acting against any steel recirculating system. Typically housed in an isolated loop separate from the main piping system, corrosion coupons never suffer the negative consequences of galvanic activity, biofilm attachment, flow rate, erosion, and most importantly, under deposit attack.Underreporting Corrosion

Although providing a relative indication of chemical inhibitor effectiveness, corrosion coupons can significantly underreport actual wall losses by a factor of 10 or greater - this often to the surprise of building owners and operators years later, and after substantial piping damage has occurred.While the threat of a piping leak is an obvious concern, a high corrosion condition can produce even more serious secondary effects which can often exist for years without being detected.

True Meaning Of MPY

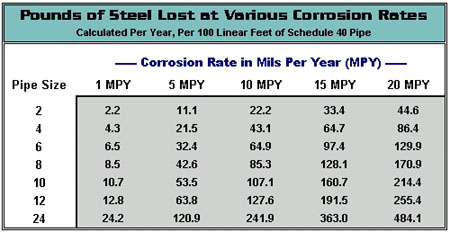

A low to moderate corrosion rate of 3 MPY at a 12-inch condenser water pipe, for example, while seemingly minor, actually translates to a physical loss of 39 pounds of steel per every 100 linear feet. At 10 MPY, approximately 128 pounds of metal is lost.Multiplied by the number of years in service, and overall length, and the true magnitude of system corrosion takes on much greater significance than when reported as simply 1, 2, or 5 mils per year.

Various weight losses for different pipe sizes and corrosion rates can be found in Table 1.

But while even a 5 MPY loss of metal can be tolerated by some piping systems for an extended period of time before resulting in a leak, it is the deposits created, and their eventual deposition, that will inevitably produce even more serious long-term secondary problems.

Steel, when corroded back into iron oxide, produces a significantly greater volume of less dense material. This, in turn, ultimately creates a substantial loss of heat transfer efficiency, constricted flow, and under deposit wall loss.

Internal Deposits Created

Given a 5 MPY corrosion rate at 12-inch pipe, approximately 2.6 cubic feet of iron oxide deposits are created per every 100 linear feet. Over a decade, and throughout a large building property, enormous volumes of foreign debris will normally accumulate unless filtered out.An estimate of deposits created for different pipe sizes and corrosion rates can be found in Table 2.

Open vs. Closed Systems

Whether a piping system is open or closed becomes far more significant where such internal deposits are concerned. Closed system deposits often remain hidden for decades, whereas a condenser water or process cooling problem will reveal itself much sooner at the cooling tower pans, strainers, condenser tubes, or heat exchanger plates.An open cooling tower typically blows down 10 percent or some percentage of its recirculation rate in order to prevent tube scaling, thereby also providing the removal of some particulates from the system. Supplemental filtration may also be in use.

Closed piping systems, by definition, contain and concentrate their foreign deposits - with the heat exchanger coils, horizontal lines, and lowest points of the system often providing ideal settlement areas. Except where a problem has already been identified, filtration is rarely provided for closed systems.

For most building operations, responsibility for the current piping condition may span across multiple property owners and an even greater number of HVAC plant operators.

Most likely, various water treatment contractors, utilizing different programs, have been employed with varying degrees of success. Corrosion monitoring may be inaccurate when employed, intermittent, or much more likely, nonexistent.

Common Problem Areas

Some areas of pipe, such as dead ends, bypass lines, basement areas, low flow sections, threaded joints, lead and lag equipment, or those periodically drained, are virtually guaranteed to exhibit significantly higher and more damaging corrosion and pitting activity.In addition, wide differences in corrosion rates are commonly found where dissimilar metals meet, at horizontal vs. vertical pipe, at supply vs. return lines, and even at the top and bottom of the same section of pipe.

Combined, such unknowns make it unlikely that a clear, thorough, and accurate understanding of current pipe condition exists.

Very often, a determination of piping integrity is made based upon assumption, visual observation, prior opinion, and unreliable data - especially that suggested by corrosion coupon results and/or the water treatment contractor.

Hard Data Required

In order to provide the greatest degree of reliability, any evaluation method must address the various sizes of pipe installed, the furthermost areas of the system, top and bottom areas, horizontal and vertical runs, and both threaded and welded pipe.A reliable piping evaluation, therefore, must address sufficient sections of pipe at its most vulnerable areas, offer accuracy and ease of use, cost effectiveness, as well as present a minimum of interference with system operations. Accommodating such needs and more, ultrasonic testing becomes the overwhelmingly preferred choice.

Taking multiple wall thickness readings at any pipe section not only identifies its current status, but more importantly, provides a virtual image and profile of its interior wall surface. The more uniform the result, the more likely that a mild and general corrosion condition exists.

A wildly varying thickness profile, in contrast, will indicate not only a pitting condition, but the high probability that even lower thickness values exist beyond those identified. Typically, a highest to lowest variation in wall thickness of 0.100 inch or more strongly suggests, by itself, a severe corrosion and pitting condition. It also raises greater concern for those most vulnerable areas of the system.

Statistical Predictions

With the original pipe wall thickness and time in service known, calculations can be made regarding the approximate speed, as indicated in mils per year, that the pipe has reached its current thickness level.Even though the pipe is not likely to have corroded evenly over time, such corrosion rate estimates are generally accurate, and will fall within a certain range of values depending upon piping service.

A theoretical minimum acceptable wall thickness calculation, or estimate of the lowest point the pipe should be allowed to safely operate, can also be made based upon material strength, system pressure, pipe diameter, thread loss, temperature, and corrosion factor.

This allows a further prediction of the remaining service life of the pipe according to the time it will take to deteriorate from its current wall thickness, at the current corrosion rate, to its minimum acceptable value. From this point, a retirement date or remaining service estimate can be offered.

With sufficient pipe locations tested, individual results can be grouped according to various criteria, and graphed to show any similarity or differences within the same piping service.

Such advanced analysis helps to identify possible data errors, but most importantly will highlight any corrosion trends within the piping system. Data analysis and trending may show, for example, a higher corrosion rate at the smaller, low flow areas, or greater losses at the return side piping.

Multiple Benefits

Overall, ultrasonic pipe testing offers tremendous benefits. For many building operators, ultrasound will very often provide the first suggestion of a corrosion problem or concern, and provide the advance notice required to address it effectively. Many years of 1 MPY corrosion coupon results may, in reality, prove to be substantially higher.Ultrasonic pipe testing can provide solid, irrefutable evidence of a suspected corrosion problem, or document that a piping system has fulfilled its useful service life and is in need of replacement. At the high cost associated with any capital piping replacement, an ultrasound report will provide the hard documentation necessary to move the project forward.

Similarly, ultrasound can save money by confirming that suspected bad pipe is still suitable for decades of additional use, or limit repairs to specific areas.

Where no problems exist, ultrasound will provide greater security, and most importantly, establish a solid baseline from which future and even more accurate and reliable estimates of corrosion rate and remaining pipe life can be made.

Bill Duncan is president of CorrView International LLC, Landing, N.J. For more information, call 973-770-7764, e-mail info@corrview.com, or visit www.corrview.com.

Publication date: 10/18/2004

Report Abusive Comment