The weather was really hot, unusually hot. The design temperature for the area was 95°F and the actual temperature was 102°. Bob got a call to go to a car dealership late Friday afternoon. The complaint was the showroom temperature was 85° and they were having a big sale Saturday morning and had to have the showroom cooler for the show.

Bob arrived and was outside at the condensing unit looking troubled when Btu Buddy appeared and asked, “What is the trouble, Bob?”

Bob said, “The owner of this business is really mad because it is Friday afternoon and he has a big sale in the morning and the showroom is 85°. Just from looking, the unit is doing all it can. I don’t know what to do next.”

Btu Buddy then said, “Boy, you are right, it is bad to have a mad owner. Here are some facts that we know without even checking the unit:

• The outside temperature is 102° and the unit was probably designed to hold the showroom up to 95° outside temperature.

• The system uses R-22.

• The unit is probably doing all it can. We need to do a performance check on it to be sure.

• We can get the unit to do a little more than its rated capacity for a short period of time.

• We can do some temporary things to reduce the load on the showroom tomorrow.

Let’s run the performance check first.”

Bob went to the truck and got his gauges, ammeter, and temperature tester and got them in place. Btu Buddy had Bob fasten the temperature tester lead to the liquid line to check the subcooling.

Bob then said, “Here are the readings:

• The suction pressure is 78 psig corresponding to 46° boiling temperature in the evaporator. That seems about right because the temperature in the space is 85°. At 75° indoor temperature it would be about 40°. It is hot in the conditioned space.

• The head pressure is a little over 300 psig. It is 102° outside so we should be condensing at about 132°. The head pressure is about right.

• The liquid line temperature is 130° with only about 2° of subcooling.

• The compressor is running at full load amperage, 100 amps.

The unit is doing all it can.”

Figure 1. This illustration shows correct expansion valve bulb and temperature test lead location. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Thomson Delmar Learning.) (Click on the image for an enlarged view.)

Bob said, “I would be afraid to add refrigerant with the head pressure running that high.”

Btu Buddy then said, “The head pressure won’t rise; we will just get more capacity from the unit. The unit capacity will rise about 1 percent for each degree of subcooling until the subcooling circuit is full, then the head pressure will rise.”

Bob charged the unit to 18° of subcooling and the head pressure remained the same.

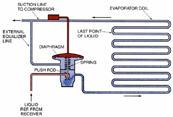

Btu Buddy then said, “Let’s find out what the true superheat is at the evaporator. This will give us more accurate information than checking the superheat like we do with a residential unit. We will fasten the temperature tester lead to the suction line at the expansion valve bulb location (Figure 1). We could get a false reading if we placed the bulb after the external equalizer line (Figure 2).”

Bob fastened the bulb to the line and insulated it and the line temperature showed 56°. He then said, “The suction boiling temperature is 45° and the suction line temperature is 56°, so the superheat is 11°. That is as close as we can get.”

Btu Buddy agreed and said, “You have tuned the system so that it is doing all it can using its air cooled capacity. If you could lower the head pressure a little, we could get even more from the unit. Here is what we will do:

Figure 2. This illustration shows what can happen if the bulb and temperature test lead are placed at the wrong location. (Click on the image for an enlarged view.)

• We will pull a water hose up here tonight and on the way home, we will stop at a store and get one of those soaker hoses that sprays a fine mist. We will get a couple of flat pieces of wood and fasten it to the wood so that in the morning we can turn on the mist under the air cooled condenser and lower the head pressure a little for even more capacity. This is a temporary setup for two reasons: use of a lot of water and the water will leave mineral deposits on the coil fins. We don’t want too much of that.

• We will get a yard sprinkler and water the roof of the showroom to lower the solar heat load on the room.

These things should get you through a bad day.”

Bob and Btu Buddy arrived at the dealership with their sprinkler system and mist system at 7:00 a.m. and got it set up.

The doors opened at 8:00 a.m. and people started to arrive. The showroom temperature was 70° at the start of the sale day. Bob turned on just the roof sprinkler to wet the roof.

At about 12:00 noon, the showroom temperature rose to 73° and there was a crowd of people in the showroom. The head pressure began to rise above 275 psig when the outside temperature went above 95° and Bob turned on the mister under the condenser and the head pressure dropped back to 260 psig.

At 4:00 p.m., the temperature in the showroom had risen to 75°, but the crowd began to leave. All was well.

At 6:00 p.m., the last customers left and the day was over. The showroom temperature never went above 75°. The owner came out to where Bob was and said, “You did a great job here today. The outdoor temperature went to over 100° and you were able to hold the showroom temperature to 75°. I understand that you went to a lot of trouble to get this equipment to outwork itself and I want to thank you for a professional job well done.”

Bob then said, “I had a lot of help from the schooling and instructors that I have had. That schooling experience was worth every bit of what it cost. I learned some tricks from my instructor that pulled us through the day. Hopefully there won’t be any more 100° sales days. This weather is really out of the normal range that the equipment is designed for.”

While riding away, Btu Buddy said, “The owner gave you a real compliment. It cost him to keep you here on overtime, but he probably made a lot of money today as a result of your help.”

Publication date:08/20/2007

Report Abusive Comment