Many sheet metal contractors are operating in an unforgiving and ultra-competitive business environment that is eroding their profits. Challenges include disconnected data, siloed teams and operations, economic pressures, labor shortages, communication gaps, poor visibility, inefficient processes — the list goes on.

At the same time, projects today are moving at ever increasing speed, and the urgency to streamline communication between the field and office is higher than it has ever been. However, you can’t meet today’s real-time construction demands with disorganized data and workflows, which result in project delays, costly rework, and razor-thin profit margins.

Fortunately, the adoption and accessibility of technology is helping to streamline these processes and has the potential to do even more. According to a study from Cemex Ventures, an estimated $5.38 billion was invested in construction technology in 2022, a fantastic milepost on the way to true industry digitization.

Contractors are turning to digital workflows for improved project outcomes, driven by greater visibility on how their processes impact projects. From streamlining ticket fittings to better materials management and analyzing shop run rates, implementing technology ultimately mitigates risk, increases project efficiency and helps contractors pivot their workforce from reactive mode to proactive mode. In fact, a 2022 study by Dodge Data & Analytics and Trimble, found that among those trade contractors using digital workflows, 58% reported better informed decision making, and 57% reported an increase in efficiency of internal processes.

Here are five technologies that sheet metal contractors should consider when taking steps to digitize their workflows:

Going Mobile

Mobile applications and devices are closing the gap between the fabrication shop and the field by empowering sheet metal contractors to easily capture data, track items, document issues, and digitize checklists in the fab shop and on the job site. For example, using a mobile application, contractors can enter fitting dimensions and preview them in 3D while on the jobsite, reducing the re-work associated with deciphering handwritten notes. Further, items are not stationary. Mobile apps can streamline status and location-tracking workflows by allowing shop managers to monitor items and see their status as they move through the shop, out the door and into the field. By leveraging barcode scanning capabilities that are available via a smartphone or tablet, contractors can associate status and location information with the ductwork.

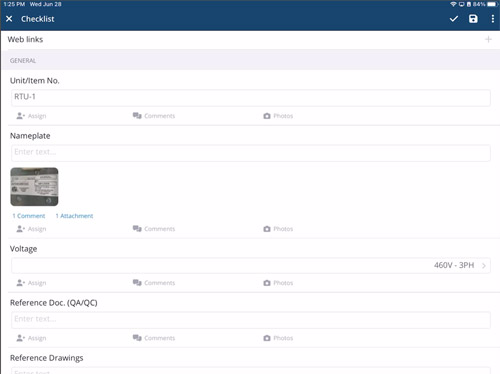

Mobile apps are even helping to digitize other traditionally paper-based activities like checklists to keep track of critical items and commissioning. With these apps, contractors can create custom forms and checklists that can be accessed, completed, and approved straight from a mobile device or tablet. In the shop or on site, the checklist is filled in with the respective details and the appropriate images and documentation can be attached. The checklist can then be approved or rejected by the lead or manager, requiring a signature for approval, simultaneously documenting the date and time of approval. Not only does this help to ensure every detail is recorded but it provides a digital record for future audit purposes.

Working from a Common Data Environment

A common data environment (CDE) is key to connecting your workflows because it provides a digital information platform that centralizes project data. While the first construction CDEs were developed to house BIM data and information, today they can also include documents like project contracts, estimates, reports, material specifications, and other information relevant to a project’s design and construction processes. A CDE effectively serves as the digital backbone for project integration, collaboration and coordination, allowing the right people (internal and external project stakeholders) to have access to the right information at the right time, enhancing decision making and enabling better project efficiency. The capabilities span beyond sharing project data; it can be used for detecting clashes, tracking issues, and even tracking “to dos.”

Software add-ons can also expand the functionality of a CDE for sheet metal contractors. For example, a fabrication add-on can provide sheet metal contractors with the capability to democratize access and modification of BIM models and fabrication spools – without requiring the fabrication department to have their own license to the BIM software. One of the greatest features of a CDE is being able to take metadata that was historically locked up in the model and make it accessible to project managers, foremen or other stakeholders. They can use it to see the manufacturer and part number of components, work package number, spool number or any other important metric or data point that your company uses to run projects.

Implementing Augmented and Mixed Reality

With augmented and mixed reality, you can now take 3D constructible models out to the field and visualize them in the context of the real world. It offers an intuitive way to interact with your information-rich BIM data, increase access to information and empower people to make decisions. Imagine walking onto the jobsite and using mixed reality to “see” clashes because another subcontractor made a change no one predicted. Catching and documenting the error from the field before the project is built eliminates rework, downtime, wasted materials and unnecessary expense. Project managers and foremen can more easily collaborate and communicate with the detailers in the office by capturing the visualization of the model on site to show them where problems or clashes may arise. And now this technology is becoming even more accessible to contractors with affordable mobile applications that offer augmented reality capabilities.

Capturing Fabrication Shop Analytics

Construction analytics can capture data from pre-construction workflows and extract intelligence from it, enabling proactive decision making so that you can check your performance before it’s too late. Using analytics throughout the process can provide key insights into your fabrication shop activities by providing insight into your fab shop’s run rates on a daily, weekly or monthly basis, how much each project and job costs, what materials you’re using and how they’re being used, how much weight in sheet metal is being used, and how much labor went into the project. You can even drill down into your material usage by category, weight, shape, and fitting quantity; this insight provides advantages for future projects too. Analytics can be run by date, project, job or any combination of three, which can lead to better decision making and improved business outcomes.

Field Layout and 3D Laser Scanning

Prefabrication of hangers, duct manifolds or spools, pads and roof curbs is beneficial, but its success is largely dependent on access to accurate, thorough site information. If there are discrepancies between the design or plan and the reality on the jobsite, or if changes on the jobsite occur that aren’t communicated well, a prefabricated component or module may not fit into the build. By using a robotic total station (RTS) and 3D laser scanning technology for layout, you can more accurately and efficiently capture complete as-built information before construction begins. This information can be exported to and from the RTS and then back into the model allowing you to plan with precision how MEP systems will be installed and alerting you to any existing limitations of the site.

Investing in technology today can take you from reactive mode to proactive mode and position your company for long-term growth. Centralized data connects people and functions, which drives consistent, scalable and predictable outcomes that can increase profit margins anywhere from 10-25%. Applying more solutions over time will enable, detailers, project managers, fab shop managers, foremen, project owners and everyone in between to have more control, more visibility and less risk, which will ultimately lead to more stable and consistent business operations and healthier margins.

Report Abusive Comment