UV Technology: What Is It?

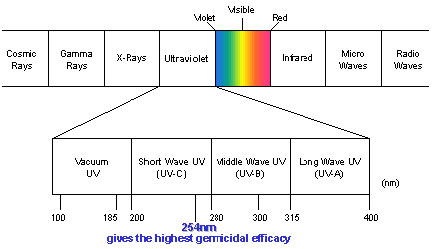

Ultraviolet is a high-energy light, which is not visible to the naked eye. Light waves are generally measured in nanometers (nm). There are three bands of useful UV light:

The sun irradiates all three bands of UV but, for the most part, only UV-A and UV-B make it through the earth's atmosphere. UV-C is filtered out with the exception of some that reaches the highest mountaintops. Experts have shown that 253.7nm is the most effective germicidal peak within the UV-C band of germicidal light. This is the wavelength of the light that Honeywell UV air treatment systems emit.

Ultraviolet technology has been used for a century as a germicidal agent. It is used in water treatment plants, hospitals, pharmacies, and kitchens.

UV Technology: How Does It Work?

A cell’s nucleic acid tends to absorb light energy from 230nm to 290nm. The germicidal effect of UV-C is caused by the absorption of these rays by the cell's deoxyribose nucleic acid (DNA). The UV-C energy scrambles the DNA coding rendering the cell nonviable, unable to reproduce, and unable to infect.

The amount of UV-C energy required to kill each pathogen is referred to as the "lethal dosage." The lethal dosage needed to kill a microorganism is a measurement of light intensity and exposure time (lethal dosage equals UV-C intensity multiplied by exposure time). Each lethal dosage differs for each type of pathogen.

Kill Rate Factors — Balancing The Equation

The following provides kill rate factors for UV lamps relative to various factors.Relating To Intensity:

The intensity of a lamp (measured in microwatts/centimeters squared) should be adequate to deliver the desired kill rate. The goal in return air applications is to kill airborne pathogens. Time is limited because they are traveling in and out of the range of the light; therefore intensity is of great importance. In coil applications the goal is to kill surface mold, so light intensity is not as important because the pathogen remains in sight of the lamp giving it “infinite” exposure time.

The accepted industry standard for UV lights is that they should effectively emit UV-C for 8,000 hours. At this point it is referred to as reaching its “end of life.”

Mercury collecting on the inside of the lamp walls contributes to the decline of UV-C output. Honeywell uses soft glass lamps that are chemically coated to minimize mercury from collecting, which helps increase effective operation.

Temperature also affects the output or intensity of a lamp. Cooler temperatures make it more difficult for UV-C energy to penetrate the glass lamp wall. (Consider it like putting tinting on a window for visible light.) Therefore the ambient temperature accompanied by velocity affects lamp performance. We recommend installing UV lights with the intent to kill airborne bacteria on the return side of the system where they will not be exposed to chilled air during the air conditioning season.

The coil irradiation model is also affected by the cooler temperatures, but because of the long exposure time, the reduction in light intensity does not affect the lethal dosage to surface molds.

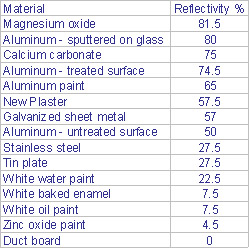

Certain duct materials can reflect UV rays better than others, thus increasing the intensity and the kill rate. UV rays do not reflect the same way visible light does. The chart at right shows the reflectivity of some example materials.

Like mercury coating the inside of the lamp wall, dust and residue can settle on the outside lamp wall that can also reduce UV-C output and therefore kill rate. To avoid this we recommend proper maintenance including quarterly lamp cleaning with a soft damp cloth. Window cleaner may be used, but be cautious of window cleaners containing any sort of oil that may leave a residue.

Relating To Time:

Exposure time is directly linked to fan speed. The slower the fan speed is, the longer a microorganism will be exposed to UV-C, and the higher the kill rate will be. Conversely, the faster the fan speed is, the shorter exposure time will be, and the lower the kill rate will be. This does not mean that the fan speed should be adjusted to increase the kill rate. What it does mean is that the fan speed should be considered when choosing a model.

The Honeywell models were tested at 2,000 cfm in a 12- by 25-inch duct. The dual lamp return air model delivers an 87 percent kill rate on Serratia marcescens, and the single lamp return air model delivers a 70 percent kill rate on the same pathogen.

The placement of the lamp is crucial in attaining the desired kill rate. In a return air application for killing the highest amount of airborne microorganisms we recommend that the device be mounted with 3 feet of open space both before and after the lamps. It is understood that this will not be possible in all applications, but the general principal should be kept in mind. In a coil irradiation application the goal is to shed light on the greatest amount of surface area that could be subjected to mold. The Honeywell coil model was found to kill 99.9 percent of colony forming Aspergillus niger mold spores when irradiated for three hours at a distance of 18 inches.

Note: High intensity UV-C energy can degrade non-metallic materials. We recommend that a minimum distance of 3 feet is maintained between the lamps and non-metallic or non-fiberglass materials. If this is not possible, aluminum-face duct tape can be used to cover the material to shield the light.

Other:

The right humidity level is important to all living things, but just as adding humidity to dry winter homes helps people, it also helps many of the microorganisms to thrive and be hardier. While it is not possible in all applications, we recommend installing return air ultraviolet air treatment systems in front of the humidifier or humidifier bypass.

Homeowner Benefits

In a survey conducted by the National Association of Home Builders (NAHB), customers rated indoor air quality as a 4.6 out of 5 in importance for their new home. Ultraviolet air treatment systems create a better indoor environment by reducing mold growth in the air conditioning cooling cools and reducing airborne bacteria blowing through the HVAC systems and into the living space. The availability of UV technology is of particular importance to people concerned about the effects of mold, bacteria, and other bioaerosols.Since so many customers are concerned about their indoor air quality and a solution is available, you have the opportunity to provide them with a complete comfort system that alleviates indoor environment problems as it heats and cools their home.

Reprinted with permission from Honeywell’s “Ultraviolet Air Treatment Systems” technical bulletin 50-8887. For more information, visit www.honeywell.com.

Publication date: 07/14/2003

Report Abusive Comment