EDITOR’S NOTE: This article is the first of a two-part series in response to the question: “Should I choose CO2 (R-744) for my refrigeration system?” It was prepared by engineers with M&M Refrigeration (www.mmrefrigeration.com) of Federalsburg, Maryland.

The application of cascade carbon dioxide and ammonia (cascade CO2/NH3) refrigerating systems has been gaining popularity in North America for the past number of years. But to correctly answer the question, “Should I choose CO2 for my refrigeration system?”, one must first identify the objectives for the refrigeration plant.

Some of the questions to ask are:

• What temperature do you need to maintain?

• Are there product freezing requirements?

• Is maintaining a reduced ammonia system charge critical (most systems under 10,000 lbs.)?

• Is having no contaminating refrigerants in the food storage, processing, and employee work areas desirable?

• Is providing a “green” refrigeration system important?

Counting Costs

Obviously cost is always an important factor in any project.

If your project does not require storage temperatures below 0° to -4°F and there is no blast freezing and very little room freezing requirement, the most cost effective and efficient refrigerating system would be a single stage economized ammonia refrigeration system.

However, if your storage temperature requirements are below -4° and there is considerable room and or blast freezing requirements, you should carefully consider the benefits of a cascade CO2/NH3 refrigerating system.

Additionally, depending upon the size of the refrigerated facility, the installed cost of a cascade CO2/NH3 refrigerating system is often less than an equivalent two-stage ammonia system. The primary factors contributing to the lower cost are smaller low stage compressors; smaller low temperature suction piping, valves, and liquid separating vessels; less piping and vessel insulation; and lower CO2 costs.

When lower temperatures than those just mentioned are required, the operating cost of a cascade CO2/NH3 refrigerating system becomes very attractive.

Testing

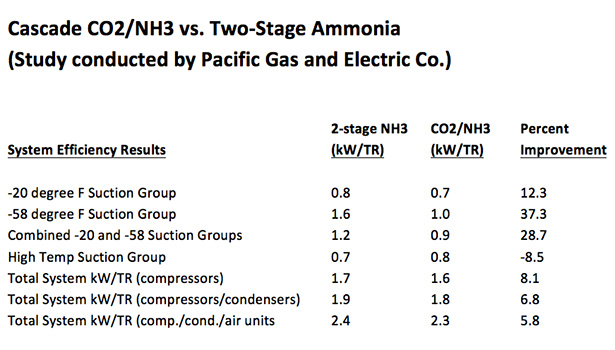

A third-party energy company conducted a comprehensive study of a cascade CO2/NH3 system modeled against an equivalent two-stage ammonia system. The project included field installed instrumentation and data acquisition equipment to monitor and evaluate the real-time performance of the refrigeration plant. The plant had refrigerated storage spaces, and ultra-low temperature blast freezers that have the ability to operate at temperatures lower than those commonly obtained with conventional ammonia systems.

The cascade CO2/NH3 system operates at the following nominal process temperatures (i.e., saturated temperatures): -58° blast freezing; -20° CO2 freezer storage; +20° CO2 coolers and docks; and +11° NH3 high stage. The conventional ammonia system was model for the following temperatures: -58° NH3 blast freezing; -20° NH3 freezer storage; and +20° NH3 high stage, coolers and docks. The efficiency of the cascade CO2/NH3 refrigerating system was measured in kilowatts per ton of refrigeration load (kW/TR).

After five months of monitored operation the comparison of the cascade CO2/NH3 refrigerating system efficiency to the efficiency calculated for the conventional two-stage ammonia system indicated that the cascade CO2/NH3 combined (-58° and -20° suction groups) efficiency showed a 28.7 percent improvement compared to the conventional ammonia system. However, the cascade CO2/NH3 overall system efficiency was reduced by the cascade heat exchangers between the CO2 compressors’ +20° saturated discharge temperature and the +11° ammonia high stage saturated suction temperature.

Moreover, the cascade CO2/NH3 system showed a 5.8 percent overall efficiency improvement over the conventional ammonia system (Table 1).

Many refrigeration engineers and service technicians have generally reached the opinion that there is very little difference between maintaining a CO2 system compared to an ammonia system.

Report Abusive Comment