Are your clients asking you whether you can hook up ice machines? If you’re subbing that work out, you’re handing away money for easy work. Ice machine installation and maintenance can be charged at a premium for work that nearly does itself.

If you’re doing a restaurant or residential HVAC install, you’ve already signed up to work with the ventilation and water lines. Why not take a few extra moments to install an ice machine in that process? It’s essentially just a couple more hookups to the water lines and making sure there’s enough clearance around the machine for airflow.

That extra service might be just the thing that attracts a new client to your company. Basic maintenance is also a snap. Just run cleaner through and change the filter out.

If the idea of getting into ice machine installation and maintenance intrigues you, here are some basic considerations for determining the make and model of the ice machine that your client needs.

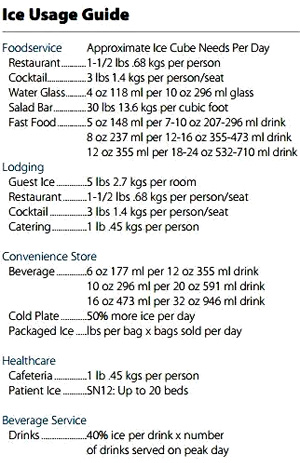

Different ice machines are suited for different functions. First you’ll want to make sure that your client will have enough ice on hand for their needs. The chart at right from Manitowoc will show you how much ice is needed on average for different applications.

Different ice machines are suited for different functions. First you’ll want to make sure that your client will have enough ice on hand for their needs. The chart at right from Manitowoc will show you how much ice is needed on average for different applications.

You’ll need to talk with your client to see how many people on average they expect to have in their establishment. That’s the minimum capacity you’ll want. It’s better to go larger to allow room to grow.

You also want to make sure that it’s going to be the right type of ice machine. There are several different configurations:

• Self-contained ice makers have both the ice making head and the storage bin where the ice is placed. This is great for hotels which have a lot of foot traffic.

• Touch-free ice and water machines work well in the self-service convenience store and buffet environments.

• Ice machines which produce over 1,000 pounds of ice in a day might be just the thing for a restaurant.

There are also different types of ice that a machine can make. You’ll need to familiarize yourself with the basic types and which types of businesses use which ones. For instance, most grocery stores need flake ice for displays. Here are the basic types:

• Cubes — Cubed ice is exactly like it sounds. Cube ice melts slowly and is used for drinks or general cooling. You can find this type of ice in restaurants and fast food places.

• Flake Ice — Flake ice is used for packing. It’s extraordinarily moldable and great for keeping things as cold as they need to be. Fish displays in supermarkets are a primary user, but it is also used in hospitals since it’s difficult to choke on.

• Nugget Ice — Nugget ice is little chewable chunks of ice. This type of ice melts faster than the cubes, but it’s less stressful for the teeth. Convenience stores and some fast food locations prefer this kind of ice.

Maintenance for most ice machines is done on a twice yearly basis. The primary tasks are scale cleaning and replacing the filters. If you’re not interested in offering maintenance contracts, it may still be a good idea to carry the equipment so that owners can handle it themselves.

Ice machine installation doesn’t take a lot of training beyond what you already know as an HVAC tech. Taking a bit of time to learn the ins and outs of installation could lead to a nice secondary stream of income, and who doesn’t want more income?

Report Abusive Comment