When thinking about artificial intelligence (AI), usually what comes to mind are movies that depict computers or robots becoming self-aware and proceeding to torment humans. Think of HAL in “2001: A Space Odyssey” or Skynet in the “Terminator” movies. Thankfully, the reality is much different.

In fact, as far as the HVACR industry is concerned, AI is already providing opportunities to improve maintenance, comfort, and energy savings. For example, some AI-enabled systems use predictive modeling to foresee when a breakdown may occur, giving contractors time to fix the issue before it results in downtime. Other systems use AI to monitor and analyze conditions inside a space, as well as outdoors, and constantly make adjustments to the environment based on the data being collected. This leads to not only more comfortable occupants, but lower energy bills for building owners.

ALREADY AVAILABLE

AI is beneficial to the HVACR industry because it allows equipment to automatically perform work that once required human effort or was previously unavailable, said Michelle Robb, director of marketing, Mitsubishi Electric Trane HVAC US LLC.

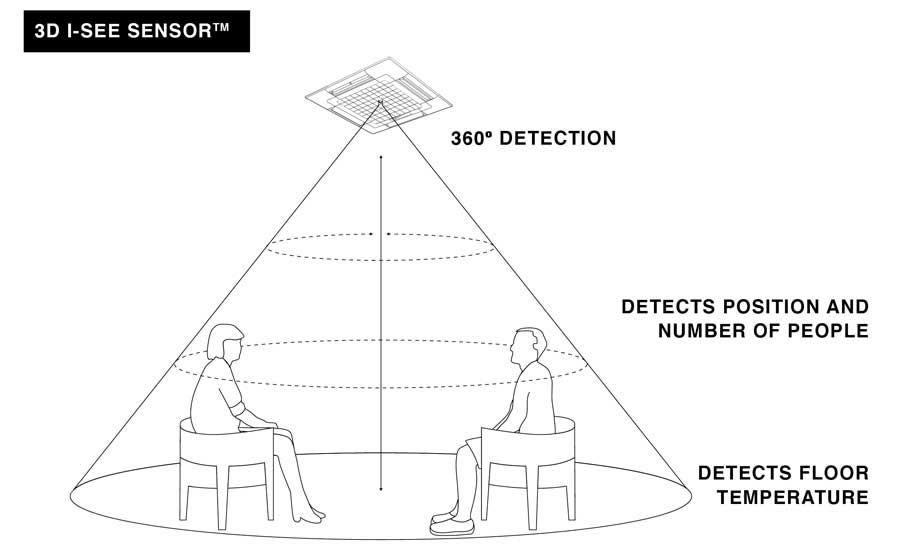

“Our 3D i-See Sensor™, for example, uses AI to detect room occupancy and automatically adjust airflow temperature and direction to maintain desired comfort level,” she said. “This technology enables our products to make smart decisions concerning comfort and operation.”

I SPY: Mitsubishi’s 3D i-See Sensor can detect the location of occupants in a room by recognizing their heat signatures and then automatically change conditioning and airflow for comfort and energy efficiency.

The 3D i-See Sensor, which is available on commercial and residential indoor units, can detect the location of occupants in a room by recognizing their heat signatures and then automatically change conditioning and airflow for comfort and energy efficiency. Once occupants are detected, the angle of the indoor unit’s vane is automatically adjusted and can be set to blow conditioned air indirectly or directly toward the occupant.

“Systems equipped with the 3D i-See Sensor reduce energy consumption according to the number of occupants in the room,” said Robb. “In addition, AI allows users to take advantage of complex time-of-use billing schemes by automatically adjusting operation to the most cost-effective heating source and turning off units in unoccupied spaces.”

Incorporating AI may also reduce downtime by predicting when a problem or maintenance issue may occur. For example, Emerson is using some elements of AI in order to detect refrigerant leaks in supermarket refrigeration systems.

“We’re researching how some of the newer techniques can be utilized for more advanced services, to detect problems faster and pinpoint what actions need to be taken to help minimize both disruptions to our customers’ operations and their operational expenses,” said John Wallace, director of innovation, Emerson Commercial and Residential Solutions.

Johnson Controls is also utilizing AI in order to become more predictive and proactive in its offerings. The company is using AI-based analytical techniques in its products, such as Johnson Controls Enterprise Management, Connected Equipment and Services, Connected Converged Security, and Mid-market Enterprise Application offerings.

“With the explosion of intelligent edge devices and data in buildings, the complexities have significantly increased,” said Sudhi Sinha, vice president and general manager of Digital Solutions, Johnson Controls. “In addition, customer expectations about how to use their facilities to tie them more closely to the commercial mission of the business are growing. Companies want to optimize not only the equipment but also their operations. Given the complexity and diversity of buildings and building systems, this work can be greatly augmented with more unconstrained AI-type techniques.”

Daikin is interested in examining how machine-to-machine (M2M) learning can assist technicians, mechanical contractors, and building facilities managers in performing trend analyses for HVAC equipment performance, energy usage, and IAQ.

“With M2M technology, our controls platforms could potentially provide reports generated through machine analysis of data and then describe recommended actions for a technician or customer to take,” said Mike Hoppe, product leader of intelligent solutions, Daikin Applied.

ONLY THE BEGINNING

AI was conceptualized back in the 1950s, but it is only through recent technological advancements that it has become more of a presence in our daily lives. For example, music and video streaming services created algorithms to predict consumer tastes and habits that have emerged into forms of AI that have really become a part of daily life without many people taking notice, said Hoppe.

“But within a commercial building, the power of M2M learning will really come into play as building owners become more aware about energy consumption and spending, comfort of the occupants, and the overall air quality inside the building,” he said. “Intelligent controls that use M2M learning could effectively provide recommendations to the building owner and technicians that result in less energy consumption, fewer HVAC repairs, and a potential lower cost of insurance due to catastrophic equipment failures.”

For technicians, the integration of AI could mean that they would no longer need to guess what operating parameters should be used after lengthy trial and error. Instead, intelligent controls could tell the technician what the problem with the equipment is and, more importantly, what to do about it, said Hoppe. To get to that point, though, AI will need to analyze massive amounts of data and a huge variety of scenarios.

That is why its implementation in the HVACR industry will initially be tied to more enterprise-level outcomes, broader system-level optimization, and limited focus on individual pieces of equipment or sensors, said Sinha.

“Keep in mind that AI gets better over time,” he said. “The commercial HVAC and controls industry is accustomed to certainty and predictability. AI introduces more agile learning and optimization methods of operating buildings and systems, and drives more continuous improvement. Eventually, AI will be used to find new boundaries for optimizations, as well as to predict new events and synthetic events that are not naturally extensible through data interpretation or alarm analysis of any one specific system, and then use external environmental factors to simulate the outcome of HVAC and control systems.”

As AI becomes utilized in a broader fashion, Wallace believes that more of the data processing will be performed at the equipment level (i.e., the controller on the equipment, sometimes called the edge device), which will lead to tighter integration of the controller installed in the equipment and a cloud-based service where the models would be created.

“To date, most of the work involving AI has been centered around gathering data from equipment and creating models to understand or predict if it is operating as intended for a given set of conditions,” he said. “For instance, if an abnormality is predicted or detected, a notification is provided, indicating that the piece of equipment may need attention of some sort.”

In order to create a predictive maintenance model that utilizes machine learning (a subset of AI), historical data will be required that details the operation of the equipment (e.g., status of the compressor, fans, temperature of the environment, etc.), as well as information about failures or operational problems that have occurred, said Wallace.

“While much of this data is present today, new sensors might be needed on the equipment to provide a more detailed prediction of its health and what actions should be taken to ensure it operates in an optimized fashion,” he said.

While AI-enabled products will no doubt continue expanding in the HVACR industry, a change in thinking may also be required. That’s because the primary challenge of designing HVACR products with AI is the same one faced by each company that integrates AI into its technologies, said Robb — recruiting talent with the skills and insight to create the AI-driven products of the future.

“This is, in part, due to challenges caused by generation gaps,” she said. “Older generations feel a level of confidence walking up to a thermostat and physically pushing a button. However, younger generations tend to expect that systems will evolve and adapt around them and that using voice commands and a generally hands-free approach to controlling the environment will become the norm.”

EXPECTATIONS

AI will likely impact all aspects of HVACR equipment and controls, but people should not expect magical results overnight, said Sinha, as end users will see the true value of AI over time, with benefits that include improved comfort, energy savings, asset life, and predictive maintenance.

“Because of the technology industry hype, people may have unrealistic expectations from AI,” he said. “Not everything is a data issue. A deep understanding of the domain and physics of HVAC can still give a lot of insights without extensive investment in AI systems. Understanding when to use AI and for what reasons is important for end users and other stakeholders.”

Wallace agreed, noting that while AI has the potential to be a very effective tool that can help end users better manage operations, it is important to remember that it is just a tool. And, like any tool, it is only effective if it is the right tool to solve the problem.

“Comfort, energy, equipment life, and maintenance are all areas that could benefit [from AI], but the key is to really understand the problem that needs to be solved and then apply the appropriate tool for the job,” he said. “Like any other new tool or technique, there needs to be justification and return on investment if there is an increased cost. Equipment manufacturers and service providers will likely need to provide the appropriate data to owners and managers in order to justify any premium or additional costs.”

Even though there is a danger of unrealistic expectations, there are already many practical examples of how AI is currently being incorporated into commercial and residential HVAC products, Robb said.

“At some points, the changes associated with AI will seem immediately revolutionary, while at other points, we might notice changes that seem mundane,” she said. “The bottom line is that AI will continue to become more sophisticated and elaborate.”

Right now, AI utilization in the HVAC industry is still emerging, and it will likely be a few years before the technology is fully implemented across most buildings, Hoppe said.

“We are only beginning to understand the possibilities of how deeply AI should be implemented into building and HVAC controls,” he said. “The full benefits of M2M learning within the controls and HVAC industry are still unknown, but we are starting to understand the significant value it can provide.”

Publication date: 2/25/2019

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment