"Operating a safe and effective salad bar or buffet requires a lot of work," points out the National Restaurant Association.

"Food safety needs to be a main ingredient to prevent food-borne illnesses."

Food safety is not a footnote with Whole Foods Market, a retailer of natural and organic foods. The company uses no artificial sweeteners, colors, flavors, or synthetic preservatives. Its Web site includes the phone number of the USDA Meat and Poultry Hotline, a storage chart for leftovers, and a cold storage chart.

Some of the company's 166 locations in North America and the United Kingdom have salad bars and/or food stations. In Atlanta's Whole Foods Market, the salad bar is 6 by 20 feet and holds 250 to 300 pounds of food. Keeping the food at a safe and constant temperature (29 degrees to 35 degrees F) is a critical requirement of the refrigeration controller.

Icing Coils

The originally installed mechanical controller in the Atlanta store was struggling to do the job."The coils were icing up and the controller wouldn't allow for defrost termination," explained Sam Swearingen, service manager for Shumate Refrigeration of Atlanta.

"You might set the defrost cycle for 40 minutes, but after 20 minutes, the defrost was complete. So for 20 minutes the salad bar was not being refrigerated. That was definitely a problem."

Shumate has a monthly service and maintenance contract with the store and had serviced the malfunctioning controller several times in the past two years.

"The salad bar is a key part of our prepared foods business," said store manager John Brown. "We probably serve about 6,000 customers per week."

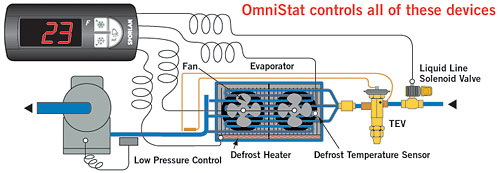

For each controller, one sensor was placed inside the salad bar cabinet below the food; the other sensor was placed on the evaporator coil.

Brown authorized the replacement. He also instituted a system of regular temperature checks and visual checks on the salad bar products' quality. The configuration now allows for 50 settable parameters for temperature, alarms, and defrosts.

Electronics' Advantages

The use of electronics in the new generation of controllers permits functions that were not possible using older mechanical controls. One of the most interesting functions is the ability to set upper and lower limits to which the device may be adjusted.For example, a beverage cooler must not only cool the product, but it must also prevent the product from freezing.

With a mechanical thermostat, the end user may set the temperature below the freezing point of the product. With the electronic device, the installer narrows the control band to temperatures above freezing but below those that would be objectionably warm. The control is then electronically locked to prevent unauthorized adjustment.

Of course, the installer can modify the control band when required. "Whole Foods is impressed that Shumate could repair and improve their equipment," said Bob Dolan, Sporlan sales engineer in the Atlanta office.

"And Shumate is also very pleased with the results of the controllers. Several other Whole Foods stores are now scheduled to receive the same controllers in their salad bars."

For more information, visit www.sporlan.com.

Publication date: 06/06/2005

Report Abusive Comment