For a given pressure, the addition of water to the ammonia will raise its temperature. At typical suction pressures, the addition of 10 percent water by weight will increase the evaporator temperature by about 4°F.

Stated another way, for a given evaporator temperature, the addition of water to the ammonia will require a lower suction pressure. For example, pure ammonia at -4° has a saturation pressure of 12.9 psig. An ammonia/ water solution of 10 percent water and 90 percent ammonia by weight at the same -4°, has a saturation pressure of 10.2 psig.

Therefore, to maintain an evaporator temperature of -4° in a system with 10 percent water contamination, the suction pressure would have to be run at 12.9 – 10.2 = 2.7 psi lower than if the water were not present.

The 4° difference represents a water concentration of slightly more than 10 percent. Therefore, the extra energy required due to the 10 percent water concentration is (1.55 –1.44)/1.44 = 7.6 percent.

To calculate the energy savings that could be achieved if the water was removed, consider a total system operating at 1,500 tons or 3,500 kilowatts (kW), a compressor run time of 6,500 hours per year, and an electricity rate of $.06 per kilowatt-hour (kWhr). Then calculate the excess energy to run the compressors at the lower suction pressure due to 10 percent water.

For example, .076 X 1,500 tons x 1.44 hp/ton X .746 kW/hp X 6,500 hr/yr X $.06kWhr) =$48,000 per year potential energy savings if the water is removed.

The effect of air contamination in industrial refrigeration systems has been well documented over many years.

Like water contamination, air contamination lowers system efficiency and increases electrical costs due to the high compressor discharge pressure caused by the presence of the air. When the air is removed with a noncondensable gas purger, the discharge pressure is reduced, system efficiency is restored, and electrical costs are reduced. The energy savings quickly pay for the cost of installing the noncondensable gas purger.

Typically, there is a 6 percent savings in energy costs for every 10 psi (0.7 bar) of excess pressure due to noncondensable air that is removed from the refrigeration system.

PROPER MAINTENANCE

Removing air and water from ammonia refrigeration systems certainly saves energy, but there are other benefits that improve system operation. On the high side of the system, operating at the lowest condensing pressure permissible means less wear and tear on compressor bearings and other mechanical parts. The lower discharge temperature also reduces oil and refrigerant breakdown and extends gasket life.

Air removal means there is less oxygen in the system, which is sometimes associated with corrosion of piping and vessels. In the same way, removing water from the refrigeration system may reduce corrosion.

MEANS OF WATER ENTRY

The most common way that water enters a system is with the air that enters the system. The air that enters the system has a certain relative humidity. Therefore, as air enters a system, a certain amount of moisture also enters the system.The moist air enters the system in two common ways. For systems that operate in a vacuum, system leaks will pull moist air into the system through the leak path. For all systems, regardless of whether they operate in a vacuum, if maintenance is performed on a portion of the system, and if this portion is not pulled into a strong vacuum before restoring it to service, that moist air remains in the system.

Noncondensable gas purgers are very effective at removing the air from the system. They are, however, less effective at removing the moisture from the system.

Another means of water entry into a system is when a water chiller develops a tube leak, and water from the tube side mixes with the ammonia on the shell side or vice versa. This can introduce large amounts of water to a system and drastic measures may be required, including replacement of the entire refrigerant charge.

LOCATION WHERE WATER TYPICALLY COLLECTS

The ammonia, air, water, and oil circulate through the refrigeration system. Water will tend to collect on the low side of the system. Only gas can leave the low side of the system.Therefore, water for the most part cannot leave the low side and will collect there. Some water can leave as water vapor, but most will stay in the low side. In two or more stage systems, the water will eventually collect in the lowest stage vessel.

The oil, also not being a gas, collects in the low side of the system, and must be routinely drained.

Alternatively, only liquid can exit the high side of the system, so air collects in the high side. This is typically near the outlet of evaporative condensers or in the coolest, low-velocity section of receivers and water-cooled condensers.

REMOVAL OF WATER AND AIR

A purger, such as the Hansen Auto-Purger, removes air from the high side of the system where air collects. Recent models of purgers, such as the Auto-Purger Plus, have also included water removal capability. In removing air from the high side, the liquid comes from the high side receiver and from condensed foul gas and is expanded into the shell side of the heat exchanger that is maintained at suction pressure (Fig. 1).In the more recent version, the liquid is taken from the pump discharge of the lowest pressure recirculator. This is where one would expect water to collect. Only ammonia gas can exit the shell side of the heat exchanger. The concentration of water gradually increases over time as liquid ammonia and water are brought in, and only ammonia gas leaves.

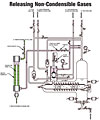

In the air and water version (Fig. 2), an ammonia gas and air mixture is taken from various locations in the high side. This gas is brought into the tube side of the shell-and-tube heat exchanger with cold liquid ammonia on the shell side. The ammonia gas in the tube condenses to liquid. The air, being noncondensable, remains a gas. When enough air is collected, it is released.

Using foul gas as a heat source for concentrating the water can only bring the concentration to about 50 percent water and 50 percent ammonia depending on the evaporating pressure and the condensing temperature. In order to concentrate the water much more, a water concentrate sensor (pressure/temperature transducer) in the shell side of the heat exchanger monitors the mixture.

When the concentration of water in the shell side of the heat exchanger gets to about 20 percent, the Auto-Purger Plus stops collecting air, isolates the mixture of ammonia and water, and energizes two electric heaters to heat the ammonia water solution even hotter to more effectively concentrate the water. The heaters remain energized until the ammonia water solution is heated to 185°.

This corresponds to a concentration of about 80-90 percent water and 10-20 percent ammonia, depending on the suction pressure. This concentrated water is then drained to a customer-supplied container (Fig. 3).

Publication date: 08/21/2006

Report Abusive Comment