In addition to consumer-driven energy improvements, federal and state energy codes have created tighter houses, resulting in very low air exchange rates, which requires supplemental mechanical ventilation systems, such as heat recovery ventilators. If adequate ventilation air is not provided, either naturally or mechanically, the home cannot "breathe" with the outside air. This situation is further exacerbated by consumers adding new exhaust fans (some of them continuously operating), or installing a new cooktop or range that utilizes a downdraft ventilation system.

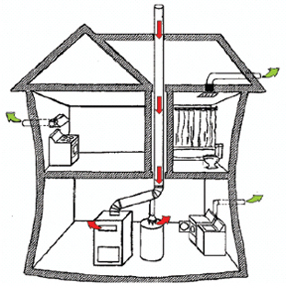

Upsetting the delicate balance of a home's ventilation rate can result in a condition referred to as depressurization. This condition is capable of overcoming the natural draft established by combustion appliances, causing the flue gases to spill into living spaces instead of being safely vented to the outdoors.

Spillage, also referred to as backdrafting, is bad news for a home's occupants in terms of indoor air quality (IAQ) and safety. Fortunately, the gas appliance installation codes in the United States have been updated numerous times over the past decade to address combustion appliances installed in unusually tight construction. Installers and service personnel need to follow these codes and the manufacturer's instructions to ensure that combustion appliances are properly vented and supplied with an adequate supply of outside air to ensure proper combustion, dilution, and ventilation.

Moreover, when a contractor enters a home on a service call or for a new installation, he needs to determine from the consumer what changes have been made to the home that may have an impact on the operation of natural draft combustion appliances. Then the contractor needs to inspect those appliances for signs of spillage, and recommend corrective action to address the cause of any potential problem. This may involve inspecting the appliance's heat exchanger and flue gas passageways and cleaning them if needed, and determining that the appliances are receiving an adequate amount of air in accordance with the codes.

HOW TO DETERMINE APPLIANCE BACKDRAFTING

In the United States, there are several established methods to determine whether there is depressurization-induced backdrafting from combustion appliances. The American Society for Testing and Materials (ASTM) has published E1998-02, "Standard Guide for Assessing Depressurization-Induced Backdrafting and Spillage from Vented Combustion Appliances." This guide describes and compares different methods for assessing the potential for, or existence of, depressurization-induced backdrafting and spillage from vented residential combustion appliances, conducted under either induced depressurization or natural conditions.The methods in this guide are applicable to draft-hood- and induced-fan-equipped gas appliances, such as furnaces, boilers, and water heaters; but the guide does not apply to power-vented or direct-vent gas appliances. The methods are not intended to identify backdrafting or spillage due to vent blockage or heat exchanger leakage, but do provide a visual assessment of the installation, which may indicate the need for a thorough inspection by a qualified technician. Users of the methods in this guide should be familiar with combustion appliance operation and with making house-tightness measurements using a blower door per another ASTM standard.

Another, more simple test for appliance spillage has existed for many years in national codes. The National Fuel Gas Code (ANSI Z223.1/NFPA 54), jointly maintained and published by the National Fire Protection Association (NFPA) and the American Gas Association (AGA), has an appendix containing a recommended procedure for safety inspection of an existing appliance installation. The International Code Council's International Fuel Gas Code also contains this appendix.

Part of this procedure is a test for spillage at the draft hood relief opening after five minutes of main burner operation using a flame of a match or candle or smoke. This test is conducted after closing all building doors and windows and all doors between the space in which the appliance is located and other building spaces. In addition, clothes dryers must be turned on, as well as any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum speed, and fireplace dampers are to be closed. All fuel-fired appliances must also be operated at their full input rate.

After the spillage test, doors, windows, exhaust fans, fireplace dampers, and any other fuel-gas-burning appliances are to be returned to their previous conditions of use. This is a quick check to ascertain the operating condition of the gas appliances; and if the appliances have checked out clean and are still spilling flue products, further investigation is warranted for conditions such as possible house depressurization. However, determining house depressurization can be elusive as some studies have shown, as there are many factors that can quickly create such a condition, and then disappear days later.

REGULATIONS ON DEPRESSURIZATION, APPLIANCE BACKDRAFTING

One example of regulations that attempt to address house depressurization and appliance backdrafting can be found in Minnesota's codes. The mechanical provisions of that state's building codes specify that the need for additional combustion and makeup air for combustion appliances should be addressed when:In addition, several alternative prescriptive paths are available to meet the requirements for protection against excessive depressurization in the 2000 Minnesota Energy Code. In that code, Chapter 7672, "Detached Single-Family and Two-Family Dwellings," specifies appliance maximum depressurization requirements for appliances with manufacturer-certified negative pressure tolerance ratings. For atmospherically vented gas and oil appliances, the limit is –5 Pascals (–0.02-inch water column), which is the same limit for decorative wood-burning appliances. An atmospherically vented water heater has a limit of –2 Pascals (–0.008-inch water column). For direct-vent and power-vented appliances, the limit is –25 Pascals or –0.10-inch water column.

In addition, a listed carbon monoxide (CO) alarm must be installed in residential dwellings. The installation of CO alarms is very important and should follow the alarm manufacturer's installation instructions and the 2005 edition of NFPA 720, "Standard for the Installation of Carbon Monoxide (CO) Warning Equipment in Dwelling Units."

WHAT'S GOING ON NORTH OF THE BORDER?

In Canada, where residential buildings are really tight, the Canadian General Standards Board (CGSB) developed a spillage test to determine the potential for pressure-induced spillage from combustion space heating appliances, water heaters, and fireplaces. That standard was adopted in 1995, based on research on appliance venting by the Canada Mortgage and Housing Corporation (CMHC).Most of the procedures described in the standard are familiar to any blower door operator who has done a worst-case depressurization test. The standard sets different limits for continuous and intermittent depressurization. However, unlike most worst-case tests used in the United States, the standard requires the use of a fireplace simulator, a two-burner camp stove, for open fireplaces (those without glass doors). The standard limits depressurization to a range between –5 Pa (Pascals) and –20 Pa, depending on the category of equipment and associated venting system. The continuous and intermittent limits for most naturally vented equipment are –5 Pa, the same limit specified by Minnesota code. In addition to referring to the performance test, Canada's 1995 National Building Code has two relevant prescriptive sections about depressurization.

"Protection against depressurization" requires that in dwellings with fuel-fired appliances vented through a chimney, "any mechanical air exhausting device, or group of devices, operated by a single control, with a net exhaust capacity greater than 75 liters/second (L/s) [160 cmf] shall be provided with makeup air ... by a supply fan rated to deliver not less than the amount by which the net exhaust rate of the device exceeds 75 L/s ... wired so that it is activated whenever the device is activated."

Meanwhile, the Canadian code also requires that "the return-air system shall be designed so that negative pressure from the circulating fan cannot: a) affect the furnace combustion air supply; or b) draw combustion products from joints or openings in the furnace or flue pipe."

Currently, there are two separate activities in Canada to develop new depressurization spillage tests for residential gas-fired and oil-fired combustion appliances, respectively. Natural Resources Canada (NRCan), the Canadian counterpart to the U.S. Department of Energy, in partnership with CMHC, carried out a project to evaluate the performance of a small sample of residential gas combustion appliances using a new depressurization spillage test procedure. The test is designed to accurately measure the amount of combustion spillage from residential gas combustion appliances and their venting systems when they operate at selected levels of depressurization, and uses carbon dioxide (CO2) that is produced in the fuel combustion process as a tracer gas.

The test method has been designed so that it will not require the use of precision space conditioning facilities during the test, which is exactly the method that has been developed for a proposed depressurization spillage test for oil-fired appliances for the Canadian Standards Association (CSA) B139 Committee on Oil Appliances.

CANADA LOOKING AT MORE RESTRICTIVE REGULATIONS

In January 2006, a CSA Task Group on depressurization held a meeting in Toronto with the intent of establishing a consensus among stakeholders (governmental, utilities, and manufacturers) to harmonize the Canadian requirements and test methods for evaluating the effects of depressurization on gas and oil appliances. At that meeting, it was agreed that work should continue toward development of a test method for determining the level of depressurization that fuel burning appliances (including wood appliances with power exhaust) can tolerate and the eventual incorporation of this test method in the relevant appliance standards.The CMHC will continue development of a testing method for all fuel type appliances to be finalized in 2007. A document will be prepared comparing all current draft and published methods and requirements, and applicable CSA standards committees will be notified of potential codes and standards activities addressing the depressurization issue. The Gas Appliance Manufacturers Association (GAMA) will become involved in this activity.

ONTARIO TAKES ACTION

Finally, in response to reported CO incidents involving either depressurization-induced backdrafting or a lack of maintenance, in January 2006, the Province of Ontario's Technical Standards and Safety Authority (TSSA) Fuels Safety Program issued a Director's Public Safety Order. The order requires a mandatory inspection of existing installations of natural draft gas boilers having inputs less than 300,000 Btuh and equipped with a draft hood installed in one- and two-family residential buildings.The order also requires all Ontario-certified gas technicians that perform service, maintenance, and/or emergency response work, to conduct a CO check in the boiler's flue (between the heat exchanger and the draft hood) and take action when the level is above 100 ppm (not an air-free sample). The check is required whenever a technician enters a home with this type of boiler, regardless of whether the homeowner has requested service on that boiler. The gas technician is also expected to examine the boiler and take action if there are signs of spillage or poor operation.

The order also provides contractors with a homeowner information sheet that outlines the requirement, the need for proper maintenance, and the recommendation of installing a CO alarm. TSSA continues to work with GAMA and other Canadian trade organizations and utilities to develop suitable requirements to address the installation of new and replacement natural draft, draft hood-equipped gas boilers in residences. GAMA has recommended that Canada's CSA B149 gas installation code be revised to properly address this issue, similar to the combustion air and ventilation requirements specified by U.S. gas installation codes, which were based on extensive gas industry research.

Publication date: 07/24/2006

Report Abusive Comment