The dispatcher calls Bob on a cold morning and explains that a customer's oil furnace will not fire on a regular basis. The customer related that the furnace would start sometimes and sometimes it would not, and he would have to reset the primary control. Bob asks for the customer's phone number, calls, and gets the homeowner's wife and tells her not to reset the furnace until he gets there, within the hour.

When Bob arrives, the wife tells him that she had not reset the control again. He asks her when the burner had been serviced last and she says about two years.

Bob then says, "It seems like just a sales pitch, but oil burners benefit from service every year. They are not like other heating equipment. They should be checked by a good technician every year."

Bob goes to the garage where the furnace is located and turns the furnace switch off. He uses a flashlight and mirror to inspect the combustion chamber for excess oil. There is no oil in the chamber, but what he sees is a very dirty combustion chamber. It has a lot of soot in it from unburned oil.

He decides to start the furnace and see what it looks like. He goes to the thermostat and sets it to call for heat. Since the furnace switch is off, the furnace will not start until he turns it on with the switch.

Bob goes to the furnace and holds the inspection door open and turns on the switch. The furnace fan and pump motor start, but it does not ignite for a few seconds. When it does ignite, a puff of black smoke comes out the inspection door and it makes a slight booming sound. The burner continues to burn, but the fire is very orange and there seems to be a lot of smoke. He steps outside to look at the flue and there is some smoke in the flue gas.

Bob turns the furnace off and is trying to get his thoughts together when Btu Buddy shows up and asks, "What is going on, Bob?"

Bob explains what the furnace is doing, but that he does not see any reason for the furnace not to fire each time.

Btu Buddy then says, "Why don't you remove the burner and give it a good examination. You are going to need to remove it to service it anyway. Did you ask the owner how long it had been since it was serviced?"

Bob responds, "It seems as though it might not have been serviced for about two years."

Btu Buddy says, "The timing is right to do a full service on the system."

Bob goes to the truck and brings in his tools and removes the burner section of the furnace. He looks it over closely.

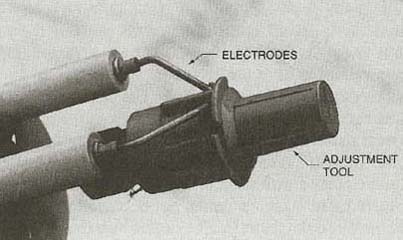

Bob says, "It looks like the fire has been burning with some smoke for a long time. The electrodes should be white, and they are black (Figure 1). I am going to start by cleaning them up and changing the oil nozzle."

"That sounds good. You are on the right track," says Btu Buddy.

Bob takes the electrodes off and starts soaking them in solvent to get them clean. He takes the mirror and inspects the combustion chamber for damage. There is some soot, but the furnace combustion chamber and heat exchanger look good.

Bob then cleans the electrodes and they become almost white again. Btu Buddy then says, "I think the electrodes were so dirty that they were leaking an arc to ground part of the time and the furnace did not fire as it should. Electricity will follow the path of least resistance and it may have depended on whether the electrodes were hot or cold where the arc may go. If it doesn't arc across the electrodes, the burner will not fire."

Bob then changes the oil filter and fills the filter cartridge with fuel oil to prevent air from being in the lines. He then changes the nozzle and keeps the nozzle line from getting air in it.

Bob puts the burner back together and places gauges on the pump to see the oil pressures. The tank is below the burner, so it is a 2-pipe system. He is ready to start the system.

He uses the furnace switch to start the system. The furnace fires up correctly. The gauges read 2 inches of Hg (mercury) inlet and 100 psig outlet. The pressures are good.

Bob then says, "The fire looks good now. I guess the furnace burner just needed a good service call." He starts to pick up his tools when Btu Buddy says, "Don't you think you should finish this professional service call by doing a flue gas analysis?"

Bob says, "Yes, you aren't going to let me get by with anything are you?"

Btu Buddy notes, "You are being paid to do a complete job, so let's do it."

Bob explains to the owner what he has found and what he has done. He also expresses again that the furnace should be examined each year at the beginning of the season to make sure it is performing correctly.

She agrees and thanks him for doing a good job.

Bob then removes the gauges and puts his tools away.

As they are riding away, Btu Buddy says, "I am glad that you ran that combustion analysis. You would not have known that the furnace was performing correctly without it. Now you have it written in your report that you did the complete job."

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Thomson Delmar Learning. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or billj@carolina.rr.com.

Publication date: 04/17/2006

Report Abusive Comment