New building codes dictate the amount of outside air that must be supplied to various spaces in such facilities. In the ASHRAE Handbook - HVAC Applications, Chapter 6, the American Society of Heating, Refrigerating, and Air-Conditioning Engineers recommends that design considerations for education facilities must take into account that today's schools are used for functions year-round. Adult education, night classes, and community functions put ever-increasing demands on these facilities. ASHRAE Standard 62 gives recommended ventilation rates for various spaces within educational facilities.

The environmental control system must be designed carefully to meet these needs. Many schools use gymnasiums as auditoriums and community meeting rooms, resulting in wide variations in use and occupancy rates. Flexibility is important in these multi-use rooms.

This article reviews some considerations HVAC professionals need to follow to meet the required ventilation rates of the education facilities, and some proven methods to control outside air.

Ventilation Requirements

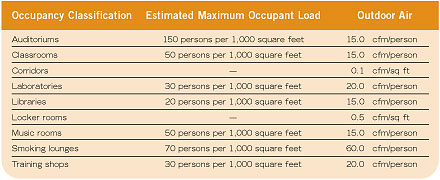

The code requirements are varied, but the new International Building Code (IBC) has been adopted by 44 states and will be the code most used in the future. The IBC gives data to determine the minimum outdoor airflow rate based on occupancy of the space and the occupancy load. (See Table 1.)The occupancy load used for the design of the ventilation system shall not be less than the number determined from the estimated maximum occupant load rate indicated in the table. The ventilation system shall be designed to supply the required rate of ventilation air continuously during the period the building is occupied.

The minimum flow rate of outdoor air that the ventilation system must be capable of supplying during the operation of the system is based upon the rate per person indicated in the table. The IBC also addresses the special needs of variable air volume (VAV) systems and requires controls to regulate the flow of outdoor air over the entire range of supply air operating rates.

How To Control Outside Air

With today's codes and mediation resulting from mold and related issues, a conscientious HVAC system designer should require verification and continual recording of the quantity of outside air introduced into the facilities.A typical practice is to have an air balancing contractor measure outside airflow during building commissioning and adjust the position of the outside air dampers to obtain the desired minimum rate of outside air supply.

However, accurately measuring outside air is technically challenging. Even if the air balance professional could provide a perfect measurement of the outside airflow rate, it will still fluctuate with changes in wind and supply airflow rates.

Also, operating conditions, such as a small change in damper position due to changes over time in the motor position or damper linkage, can change the outside airflow rate drastically. This results in either not enough outside air being supplied to the building, or being a source of wasted energy because too much air is supplied to the system.

Outside Air Measurement

In the past, a common method to measure ventilation was to determine the difference between return air and supply air measuring stations. This difference was the approximate amount of outside air introduced into the building.However, if each airflow-measuring station in the supply and return air was 3-percent accurate, an error rate of 6 percent for the total system air could result.

For example, if there is 100,000-cfm supply air system with a 6-percent error rate (or 6,000 cfm) compared to the requirement of 15,000 cfm outside air, the total error of the outside air system is 40 percent. This demonstrates the driving trend toward today's more preferred system: direct measurement of outside air. By directly measuring outside air, the system designer minimizes the error and increases the accuracy.

In the last few years, several products have come into the market that are designed to directly control the outside air introduced into a building.

One method uses two outside air-measuring stations to control the outside airflow through the unit. One station is designed for 25-percent airflow and the other sized for 75-percent flow.

The control scheme is de-signed to keep the pressure signal viable for control. These stations stage their operation to keep the signal pressure useable, thus maintaining ventilation rates.

Another method integrates an air-measuring station into an outdoor air intake louver. Stability and control signals are amplified in this scheme, since air is measured at the highest velocity point in the outside air system. It is important that the manufacturer test this as a package. The louver can impact the performance of the air-measuring station if it is not designed and tested as a combination.

The fan-injection method consists of a separate fan and air-measuring station and is used to control the minimum outside air introduced into the HVAC system. These types of systems require extra space to install. Also, the extra energy required to operate the injection fan must be taken into consideration. It is possible that the injection fan could overpower the system and relieve air through the outside air damper.

Measuring and controlling outside air with an integrated air measuring station/damper assembly is becoming more popular. For constant-volume applications, these are usually set up to maintain minimum ventilation; a separate, standard damper for economizer operation obtains free cooling.

Accuracy is increased in measuring and controlling the minimum outside air versus the total air because the signal (or velocity pressure) from Pitot arrays is limited to 300 to 400 fpm on the low end. (The velocity pressure at that point is only 0.01 inches wg.)

Typical commercially available transducers have limited accuracy at these low pressures. By directly measuring and maintaining minimum ventilation rates, again the error rate is minimized.

Outside Air Management

It is desirable to be able to read and control the minimum ventilation rate on constant-volume systems, but it is an International Mechanical Code (IMC) requirement on all VAV systems.Because of changes in the mixed air plenum when VAV systems reduce airflow, accuracy will increase by measuring the entire outside air. To measure the total outside air, flow sensors have been built into the entire outside air damper arrangement. This is one of those recently introduced products to control outside air into facilities.

This flow sensor consists of a flow-measuring station integrated within a low-leakage damper with airfoil blades. Fixed monitoring blades contain air pressure-sensing ports, one open to the upstream edge to sense total pressure and the other downstream to sense static pressure. The resulting output goes to an onboard differential pressure transducer that internally adjusts damper position to maintain required minimum airflow.

The control damper, designed for modulating operation, utilizes standard blade and jamb seals for low leakage. Strategically placed air-sensing blades measure air-stream velocity. Air tubing/piping connections provided connect the sensing blades to the controller.

Using the velocity information provided by the sensing blades, the controller calculates a cfm value that will be compared to the design cfm setpoint as determined by the particular mode of operation of the HVAC system. This setpoint will correspond to the minimum outside air ventilation required by the system design to meet ASHRAE Standard 62. The controller will adjust the actuator to position the blades so the airflow reaches the desired level, which is based on the difference between the actual cfm reading and the desired setpoint.

When total system air is reduced, the outside air damper senses this reduction and opens more fully to maintain proper ventilation. The return air damper correspondingly closes, helping keep the mixed air plenum within the control range.

The pressure readings on this type of system are usually between 0.10 and 0.40 inches wg, providing a usable signal output from the damper. Improvements in accuracy are more predictable.

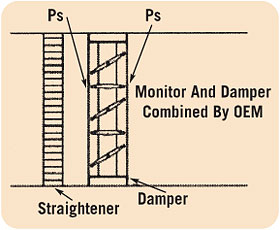

Figure 1 shows a combination damper-flow station. Figure 2 shows the control logic for control and monitoring outside air within this system. The velocity pressure is calculated from Pt-Ps and maintained constant by modulating the minimum outside air blades themselves. This control damper is designed to measure airflow across the blades and, by monitoring the blades, controls the airflow to a desired volume. As the supply fan reduces airflow, the outside air damper/monitor senses the reduction and opens the damper to maintain pressure.

The three sections include:

1. Damper - This discharge section contains aerodynamic blades that can modulate from fully open to fully closed, controlled by a reversible damper gear motor.

2. Air measuring station - This center section contains stationary aerodynamic blades that contain air velocity-sensing glands on the upstream and downstream sides. Velocity pressure is measured across this differential pressure-sensing device. A number of instruments are available to read this pressure drop and determine air velocity across the damper.

3. Air-straightening section - This inlet section contains a honeycomb media to straighten the flow of incoming air and prevent turbulence, allowing the air-measuring station to more accurately determine air velocity.

This has proven to be simple and reliable in the field when used for managing the entire outside air damper. Regardless of the return air pressure drop, the outside air damper will work the mixing box and modulate the outside damper and the dependently controlled return damper to maintain velocity pressure.

If economizer controls are included, they will permit more than the minimum ventilation maintained by this outside dam-per/monitor if temperature conditions permit. At the low Pv encountered, this method can read accurately. The dampers are sized as described for the differential pressure method.

Certified Performance

Measuring airflow is the first step to controlling airflow. It is essential that the air-measuring and management devices be accurate. ANSI/AMCA Standard 610-95 establishes a uniform test method for measuring the performance capability and accuracy of airflow measurement stations under varied flow rates and conditions.This standard covers airflow measurement devices that stand alone or are integrated with dampers, louvers, etc., as applied in HVAC systems. This standard includes single- and multi-point, Pitot-type thermal anemometers, thermistors, vortex-shedding sensors, and orifices.

Please note that the manufacturer may test management devices to these standards, but that does not mean their claims are certified. The AMCA 611 certified ratings program provides assurance that the manufacturer's published data are reliable and accurate. This program also provides a procedure for verifying performance ratings on a regular schedule by check testing the certified ratings of the airflow-measuring product.

Because of the number of prolific claims regarding the accuracy of air-measuring products, you should specify AMCA 611 certification to ensure accuracy of the air-measuring product.

HVAC professionals must have knowledge of proper ventilation control and code requirements for educational facilities in order to prevent Sick Building Syndrome and minimize the spread of respiratory diseases.

Proper amounts of outside air must be introduced whenever the building is occupied. A good solution is to direct measurement of total outside air and closing the return air dampers when pressure reductions are sensed across the outside air damper.

ASHRAE Standard 62 requires that a "substantial majority" of building occupants suffer no discomfort from air quality and that they are not exposed to health risks associated with air quality. The IBC and ASHRAE 62 require the need to maintain the ventilation rate for both VAV and constant volume systems.

Tom Edwards has been president of Ruskin since 1995. The company manufactures air distribution and control products via multiple channels of distribution. Robert Van Becelaere is the vice president of engineering for Ruskin Manufacturing, a division of Tomkins Industries.

Publication date: 11/08/2004

Report Abusive Comment