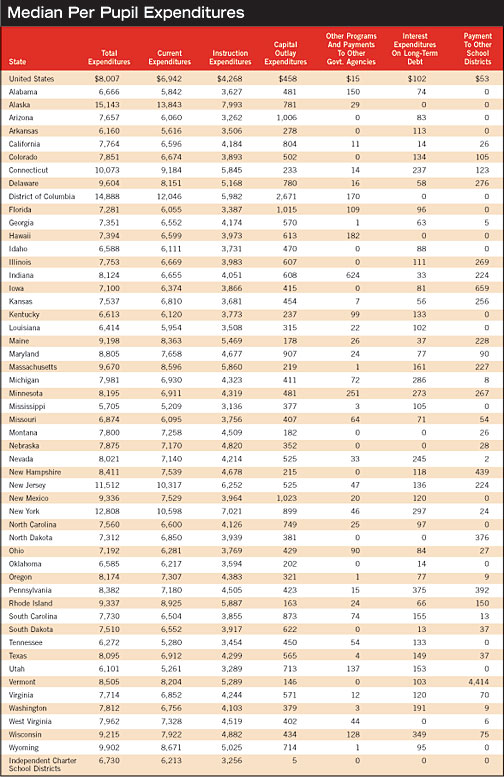

According to Education Statistics Quarterly, "The median total expenditure by school district in the nation was $8,007 per student. This included current operating expenditures, capital outlays (for school construction and equipment), expenditures for programs other than elementary/secondary education (such as adult education and community service programs), interest payments on long-term debt, and payments to state and local governments."

The quarterly, a publication of the National Center for Education Statistics (NCES, www.nces.ed.gov), stated, "A major barrier to schools' improving their facilities is the substantial cost involved. If schools are unable to obtain the funding they need to perform maintenance or construct new buildings when necessary, facilities' problems multiply, which can result not only in health and safety problems, but also in increased costs of repairs."

Background Figures

According to the 1999 NCES survey:Each of the following environmental conditions was rated as unsatisfactory by about one-fifth of the schools: heating, IAQ, acoustics or noise control, and physical security. Twelve percent of schools reported unsatisfactory lighting.

The total amount needed by schools was estimated at approximately $127 billion.

According to projections published by the NCES, "from 2000-01 to 2012-13, current expenditures in constant 2001-02 dollars per pupil in fall enrollment are projected to increase from 14 to 37 percent, depending on the alternatives schools choose to solve their particular problems." Table 1 shows which states are spending the most on their schools' capital outlays, where HVAC repairs/re-placement falls.

The following cases demonstrate the kind of effect HVAC equipment selection can have on ventilation, IAQ, acoustics, and especially, the bottom line.

Ventilation And Acoustics

Alabama spends slightly more than the national average on school capital expenditures. However, repair budgets can be altered in an instant due to damage from a natural disaster.On Nov. 10, 2002, a tornado cut a 43-mile-long, 1,100-foot-wide swath of destruction through northwest Alabama. At 7:10 p.m., it reached the rural town of Carbon Hill and plowed through the town's elementary school. Because of the time of day, no children or teachers were on campus and no one was hurt, but the school building was destroyed. The Walker County School District organized a plan to rebuild. The new school is set to open this fall.

With the perceived perception of ventilation being subpar in many schools, it's not surprising that the designers for the new school building paid close attention to the new ventilation system.

The mechanical engineering firm, Edmonds Engineering (Birmingham, Ala.), requested estimates for lined sheet metal air ducts. Fluctuating sheet metal prices, however, raised the estimated cost higher than the district's budget could handle.

"This school is a $15 million project, but we've had to work hard to stay within budget," said Dan Blackman, vice president of Edmonds Engineering. Changing to fiberglass duct board lowered the cost approximately $120,000, Blackman said.

Operational efficiency, or sustainability as it is now called, was also part of the engineers' mandates. Mickey Barrentine, maintenance supervisor for Walker County Schools, explained, "We would not have installed it if it was only going to save money during construction and still cost us money down the road."

According to manufacturer Johns Manville, Denver, fiberglass duct board delivers conditioned air at the desired temperatures, and reduces or eliminates condensation problems. Moreover, "standard fiberglass duct board installation methods provide extremely low system leakage, enhancing comfort and minimizing energy loss," the company said.

The NCES survey also cited sound control as being critical. "Classrooms can be noisy places," pointed out architect Rick Lathan. "The duct board is going to do a lot to dampen the sound that travels through the duct system, including cross talk from other classrooms and air-handling noise."

The Efficiency Picture

Ohio falls close to the middle of capital outlay expenditures, at $429 per student. Mason City Schools is one of Ohio's largest and fastest-growing school districts, serving more than 9,000 students in seven buildings. The school district recently held a competitive bid process for a $1.8 million contract to supply air-handling and climate control equipment.Construction will include the new Mason City Schools Early Childhood Center and an addition to the Intermediate Campus. Trane, Piscataway, N.J., will supply a 300-ton RTAC chiller, modular air-handling units, variable air volume (VAV) controllers, and its Tracer Summit building automation system.

The chiller complies with standards for energy efficiency developed by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE).

According to Shelly Benesh Hausman, public information officer, Mason City Schools, "This contract will allow us to integrate all of our different school buildings into one common system operated and maintained by Trane equipment and controls."

"The chiller is engineered for lower life-cycle costs and reliability through design simplicity, which is particularly important for schools," said Gary Luepke, senior systems engineer, Trane.

"Our building automation system combines hardware components and engineering applications into a single, logical, and efficient system that makes it ideal for customers who need to consolidate various processes, even across different buildings."

The manufacturer has supplied Mason City Schools with HVAC equipment and controls since Mason Middle School was built 10 years ago. The district has had a maintenance contract with Trane since 1997.

"Education facilities across the country are looking for ways to improve learning environments for students and lower operating costs," commented Luepke.

The company also will provide HVAC systems for New Bethel Middle School, Bryant, Ark., where capital outlay expenditures are only $278 per student.

The school is looking to receive the title of "first high-performance and Leadership in Energy and Environmental Design for New Construction and Major Renovations (LEED-NC) Green Building Certified school to be constructed in Arkansas." LEED is the United States Green Building Council's (USGBC) voluntary standard for developing sustainable buildings.

Trane is supplying two FAXA packaged fresh air units to provide humidity control of ventilation air; 50 Varitrane VAV units; 35 Varitrane VAV reheat units to control space temperature; 32 16-SEER XL16i two-stage, DX condensing units and variable-speed air handlers serving classrooms; four 14-SEER XL14i DX condensing units and air handlers for administration offices; and the Tracer Summit building automation system to control climate and lighting systems.

IAQ And Energy Savings Go Hand In Hand

Minnesota is tied with Alabama in its school capital outlay expenditures: $481 per student. In Robbinsdale Area School District 281, officials wanted to use some of that outlay to renovate HVAC equipment with an eye toward improved IAQ, sustainability, and maintenance savings. The district comprises 26 facilities on 422 acres, with a K-12 student population of 13,000.According to Ron Bjorklund, district-wide maintenance supervisor, an extensive renovation program is now under way. "We have gradually been replacing unit ventilators with central air-handling units [AHUs] that supply tempered air to fan coil units with a dedicated outdoor air path," he said.

Approximately half of the district's 90 AHUs are equipped with UVC lights from Steril-Aire Inc., Burbank, Calif. Bjorklund said that the UVC-treated coils appear clean even after three years with no sign of mold growth - which was verified by testing petri dish samples from coil surfaces. Maintenance required on the UVC devices is the annual tube changeout.

"Our indoor air quality is 100 percent better than what we had with unit ventilators," Bjorkland states. "In at least one facility, we believe there has been a decline in respiratory illnesses since the renovation. We will continue to monitor results."

Publication date: 08/08/2005

Report Abusive Comment