In evaporative cooling products, cooling is accomplished by evaporating a small portion of the recirculating water as it flows through the unit. As this water evaporates, the dissolved solids originally present in the water remain behind and, if not controlled, their concentration will increase rapidly. This can lead to corrosion, scale, or biological fouling which may negatively affect heat transfer as well as the longevity of the unit and other system components.

Each of these aspects of water quality is discussed in greater detail below. Since the quality of the ambient air and make-up water varies significantly from job site to job site, Baltimore Aircoil strongly recommends obtaining the services of a competent water treatment agency prior to the initial startup of the evaporative cooling equipment. Additionally, to protect against the risk of Legionella contamination, the cooling equipment should never be operated without adequate biological control.

Corrosion And Scale Control

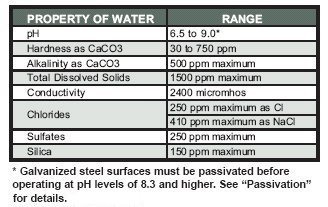

To control corrosion and scale, the water chemistry of the recirculating water must be maintained within certain parameters. The specific measures required vary from system to system and are dependent on the chemistry of the make-up water, the metallurgy of the piping and heat transfer devices exposed to the recirculating water, and the temperatures at which the system will be operating. Bleed/blowdown, the continuous flow of a small portion of the recirculating water to a drain, is used to control the concentration of dissolved solids. On rare occasions this may be adequate to control scale and corrosion. More often, however, chemical scale and corrosion inhibitors are necessary, which raise the allowable level of dissolved solids without the risk of scale and corrosion.Chemically treated water should be kept within the guidelines given in Table 1, or within the limits provided by your water treatment specialist. In cases where bleed/blowdown alone is being employed for corrosion and scale control, without chemical treatment, your water treatment specialist may recommend more conservative limits than those shown in Table 1.

Chemical treatment programs must meet the following requirements:

1. The chemicals must be compatible with the unit materials of construction as well as other materials used in the system (pipe, heat exchanger, etc.)

2. Chemical scale and corrosion inhibitors, and particularly acid (if used) should be introduced into the circulating water through automatic feeders at a point in the system where total mixing and dilution occur before reaching the evaporative cooling equipment. The preferred injection point for chemical scale and corrosion inhibitors is on the discharge side of the system circulating pump(s). These chemicals should not be batch fed directly into the unit's cold water basin or water distribution system, as this can severely damage areas directly contacted.

3. When chlorine is added to the system, free residual should not exceed 1 ppm. Exceeding this limit may accelerate corrosion.

4. Closed circuit cooling towers and condensers only: Unless a common remote sump is utilized, each cell of a multi-cell coil product must be treated as a separate entity, even if the cold water basins are flumed together or equalized.

Passivation

When new systems are first commissioned, special measures should be taken to ensure that galvanized steel surfaces are properly passivated to provide maximum protection from corrosion. Passivation is the formation of a protective, passive, oxide layer on galvanized steel surfaces. To ensure the galvanized steel surfaces are passivated, the pH of circulating water should be kept between 7.0 and 8.2 for four to eight weeks after startup, or until new zinc surfaces turn dull gray in color. If white deposits form on galvanized steel surfaces after the pH is returned to normal service levels, it may be necessary to repeat the passivation process.Note: Stainless steel units and units protected by a corrosion protection system do not require passivation.

Biological Control

The warm, oxygen and nutrient rich environment inside evaporative cooling equipment provides an ideal environment conducive to the growth of algae, slime, and other microorganisms. Uncontrolled, this can reduce heat transfer, promote corrosion, and promote the growth of potentially harmful organisms such as Legionella.To avoid biological contamination and minimize the risk of Legionella, a biocide treatment program should be initiated at startup, and administered on a regular basis thereafter in accordance with the treatment supplier's instructions. Bleed/blowdown or chemical treatment used for corrosion and scale control alone is not adequate for control of biological contamination.

Solid or granular biocides should be introduced through a chemical "pot" feeder installed in parallel with the system circulating pump(s). Dilute liquid biocides may be added directly to the cold water basin. If ozone water treatment is used, ozone concentrations should not exceed 0.5 ppm.

Initial Startup And Startup Following A Shutdown

To minimize the risk of biological contamination during a shutdown period of three days or more, it is recommended that the entire system (evaporative cooling equipment, system piping, heat exchangers, etc.) be drained. To resume operation of a drained system and at initial startup, clean all debris from the cold water basin and fill the system with fresh water. Then execute one of the following biocide treatment programs while operating the circulating pump(s) and prior to operating the unit fans:1. Resume treatment with the biocide that was used prior to shutdown. Then run the pump only while maintaining the maximum recommended biocide residual for a sufficient period of time (residual and time will vary with the biocide) as recommended by the water treatment supplier. Only after this treatment period is completed should the fan(s) be started.

2. Check the pH of the circulating water and, if necessary, adjust it to 7.0 to 7.6. Then, running the pump only, treat the system with sodium hypochlorite to maintain a level of 4 to 5 mg/l (ppm) free chlorine (as Cl2) over a six hour period. Test kits that can be used to measure the free residual of chlorine are commercially available. Only after this treatment period is completed should the fan(s) be started.

When it is not practical to drain the system during shutdown periods, a bypass line with shut-off valves should be installed to permit the recirculating water to be circulated throughout the system, including the unit basin, while bypassing the fill section of the evaporative cooling equipment (fans should remain off). The system should be treated per one of the two methods described above prior to restarting the unit.

System Cleaning For Coil Products

This section is applicable to closed circuit cooling cowers and evaporative condensers only.The outside surface of the heat exchanger coil may require occasional cleaning. The chemicals used for cleaning must be compatible with the materials being treated (the outside of a standard coil is galvanized steel). For specific recommendations on coil cleaning, consult a qualified water treatment specialist.

Closed Circuit Cooling Towers

When the following precautions are taken, an alkaline solution used to clean condenser water systems prior to startup may be circulated through the coil of a closed circuit cooling tower.

1. Limit the duration of the cleaning to one day.

2. The temperature of the solution should never exceed 100 degrees F.

3. The maximum concentration of chemicals in the circulation solution should not exceed any of the following:

5 percent sodium hydroxide

5 percent sodium metasilicate

2 percent sodium carbonate

2 percent tetra sodium pyrophosphate

0.5 percent trisodium phosphate

0.5 percent sodium nitrite

10 percent butyl cellosolve

Evaporative Condensers

The installation and manufacturing processes commonly used for field-assembled steel-piped refrigeration systems leave weld byproducts inside coils and connecting piping. It is common practice to install filters and/or strainers that remove contaminants during initial system operation. Shortly after system startup, the filters and/or strainers should be cleaned or replaced.

Reprinted with permission from the Baltimore Aircoil Co. technical resources data sheet "Water Quality Guidelines." For more information, visit www.baltimoreaircoil.com.

Publication date: 02/07/2005

Report Abusive Comment