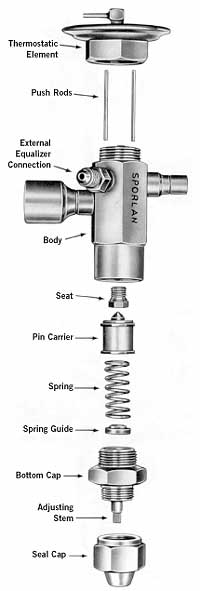

The conventional TXV is controlled by springs, bellows, and push rods. (See Figure 1.) The spring force is a closing force on the TXV. The evaporator pressure, which acts under the thermostatic element's diaphragm, is also a closing force. An opening force is the remote bulb force, which acts on top of the thermostatic element's diaphragm.

There is also a liquid force from the liquid line, which acts on the face of the needle valve and has a tendency to open the valve. However, this force is cancelled out when using a balanced port TXV. Working together, these forces maintain a constant evaporator superheat in a refrigeration system. There are no electronic devices associated with a conventional TXV.

EEVs

The electronic expansion valve (EEV) operates with a much more sophisticated design. EEVs control the flow of refrigerant entering a direct expansion evaporator. They do this in response to signals sent to them by an electronic controller. A small motor is used to open and close the valve port. The motor is called a step or stepper motor. Step motors do not rotate continuously. They are controlled by an electronic controller and rotate a fraction of a revolution for each signal sent to them by the electronic controller. The step motor is driven by a gear train, which positions a pin in a port in which refrigerant flows. A cutaway of an EEV with step motor and drive assembly is shown in Figure 2.Step motors can run at 200 steps per second and can return to their exact position very quickly. The controller remembers the number of step signals sent by the controller. This makes it possible for the controller to return the valve to any previous position at any time. This gives the valve very accurate control of refrigerant that flows through it. Most of these EEVs have 1,596 steps of control and each step is 0.0000783 inches.

Sensors

The electronic signals sent by the controller to the EEV are usually done by a thermistor connected to discharge airflow in the refrigerated case. A thermistor is nothing but a resistor that changes its resistance as its temperature changes. Other sensors are often located at the evaporator inlet and outlet to sense evaporator superheat. This protects the compressor from any liquid floodback under low superheat conditions.Pressure transducers can also be wired to the controller for pressure/temperature and superheat control. Pressure transducers generally have three wires. Two wires supply power and the third is an output signal. Generally, as system pressure increases, the voltage sent out by the signal wire will increase. The controller uses this voltage to calculate the temperature of the refrigerant with the use of a pressure/temperature table programmed into the controller.

A combination of compressor floodback protection and the ability to maintain refrigerator case discharge air temperature set point control makes the EEV useful in many diverse applications. Some EEV controllers can also be programmed for custom control applications.

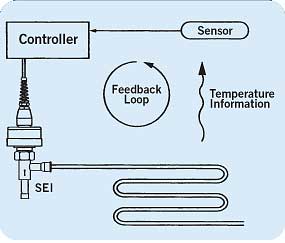

Feedback Loop

The controller may open the EEV too much and cause an overcooling condition. The sensors connected to the refrigeration system and wired to the controller will sense this overcooling condition and feed this information to the electronic controller and the EEV. This will cause the step motor to move in the closing direction and close the valve more. The feedback loop is shown in Figure 3.Next month: Advanced aspects of EEVs will be covered in the Sept. 6 issue of The News.

John Tomczyk is a professor of HVACR at Ferris State University, Big Rapids, Mich., and the author of Troubleshooting and Servicing Modern Air Conditioning & Refrigeration Systems, published by ESCO Press. To order, call 800-726-9696. Tomczyk can be reached by e-mail at tomczykj@tucker-usa.com.

Publication date: 08/02/2004

Report Abusive Comment